Hydraulic dock levellers

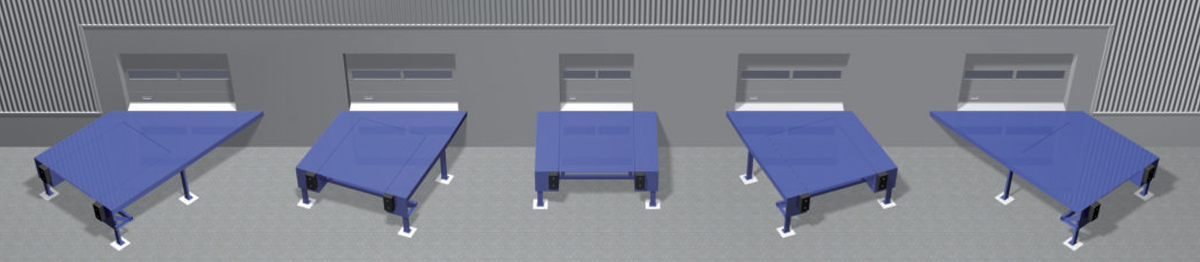

For every application

Hydraulic dock levellers from Novoferm are available with feed and in various designs. As a highlight, we offer you our NovoDock EVO X as the next generation dock leveller, as well as the NovoDock L730i as the ideal ISO loading point.

Get an overview for yourself!

Dock levellers overview

Comparison and properties

Comparison of dock levellers with feed

| Product features | L730i ISO | L730i Standard | L530 | L530R | P1530 | L550i | VL6020 | |

| with feed | ● | ● | ● | ● | ● | ● | ● | |

| with folding wedge | ||||||||

| ISO dock | ● | ● | ||||||

Option packages | GreenPlus | ● | ● | o | o | o | ● | |

| GreenSLOD | o | o | o | |||||

| IsoPlus | o | o | o | o | ||||

| DoorPlus | o | o | o | o | o | o | ||

| SafetyPlus | o | o | o | o | o | o | ||

| Nominal load according to EN 1398 in kN | 60 | 60 | 60 | 60 | 60 | 100 | 60/20 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 3.000 | 2.000, 2.500, 3.000 | 2.000, 2.500, 3.000 | 2.000, 2.500, 2.750, 3.000 | 2.000, 2.440 (2.500), 3.000 | 2.000, 2.500, 3.000, 3.500, 4.000, 4.500 | 3.500, 4.000, 4.500, 5.000 | |

| Nominal widths in mm | 2.000, 2.250 | 2.000, 2.250 | 1.750, 2.000, 2.250, 2.400 | 1.710, 1.750, 1.960, 2.000, 2.060, 2.100, 2.160, 2.200, 2.250 | 2.000, 2.200, 2.250 | 2.000, 2.250, 2.400 | 2.000 | |

Overall height | 600 mm | up to 3,000 mm (NL) | up to 3,000 mm (NL) | |||||

| 700 mm/725 mm1) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | up to 2,500 mm (NL) | ||||

| 800 mm /830 mm2) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | at 3,000 mm (NL) | |||||

| 900 mm/1200 mm3) | at 3,000 mm (NL) | at 3,000 mm (NL) | from 3,500 mm (NL) | up to 5,000 mm (NL) | ||||

| Feed/folding wedge length in mm | ● 700 / o 1.000 | ● 500 / o 700 / o 1,000 | ● 500 / o 1.000 | ● 500 / o 1.000 | ● 500 / o 1.000 | 500 | ● 500 / o 1.000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | IP 65 | IP 65 | IP 65 | IP 65 | IP 65 | IP 54 | |

| Motor power in kW | max. 1.5 | max. 1.5 | max. 1.5 | max. 1.5 | max. 1.5 | max. 1.5 | max. 1.5 | |

| Design feature | Plateau of tear plate in mm | 8/10 | 8/10 | 8/10 | 8/10 | 8/10 | 10/12 | 8/10 |

| Feed/folding wedge tear plate in mm | 12/14 | 12/14 | 12/14 | 12/14 | 12/14 | 15/17 | 15/17 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 330 (405)/300 (315) | 330 (405)/300 (315) | |||||

| Nominal length 2000, overall height 700 /7251)/8302) | 350 (400)/370 (400) | 320/3404) | 360 (440)/400 (435) | 360 (440)/400 (435) | 360 (460)/380 (430) | 300/400 | ||

| Nominal length 2250, overall height 600 | ||||||||

| Nominal length 2500, overall height 600 | 430 (500)/290 (280) | 430 (500)/290 (280) | ||||||

| Nominal length 2500, overall height 700 /7251)/8302) | 400 (430)/370 (370) | 370/3104) | 470 (540)/370 (390) | 470 (540)/370 (390) | 470 (590)/350 (390) | 300/400 | ||

| Nominal length 2750, overall height 600 | 400 (500)/270 (270) | |||||||

| Nominal length 2750, overall height 700 | 430 (530)/350 (370) | |||||||

| Nominal length 3000, overall height 600 | 420 (475)/270 (260) | 420 (475)/270 (260) | ||||||

| Nominal length 3000, overall height 700/7251)/8302) | 340 (370)/330 (350) | 310/3104) | 480 (565)/400 (390) | 480 (565)/400 (390) | 480 (590)/400 (380) | |||

| Nominal length 3000, overall height 800 /9002) | 400 (430)/370 (400) | 370/3504) | 370/400 | |||||

| Nominal length 3500, overall height 800 | ||||||||

| Nominal length 3500, overall height 900/12003) | 450/400 | 400/600 | ||||||

| Nominal length 4000, overall height 900/12003) | 450/400 | 400/650 | ||||||

| Nominal length 4500, overall height 900/12003) | 450/400 | 400/750 | ||||||

| Nominal length 5000, overall height 1200 | 400/775 | |||||||

| Maximum permissible inclination according to EN 1398 | 12,5 % | 12,5 % | 12,5 % | 12,5 % | 12,5 % | 12,5 % | 12,5 % | |

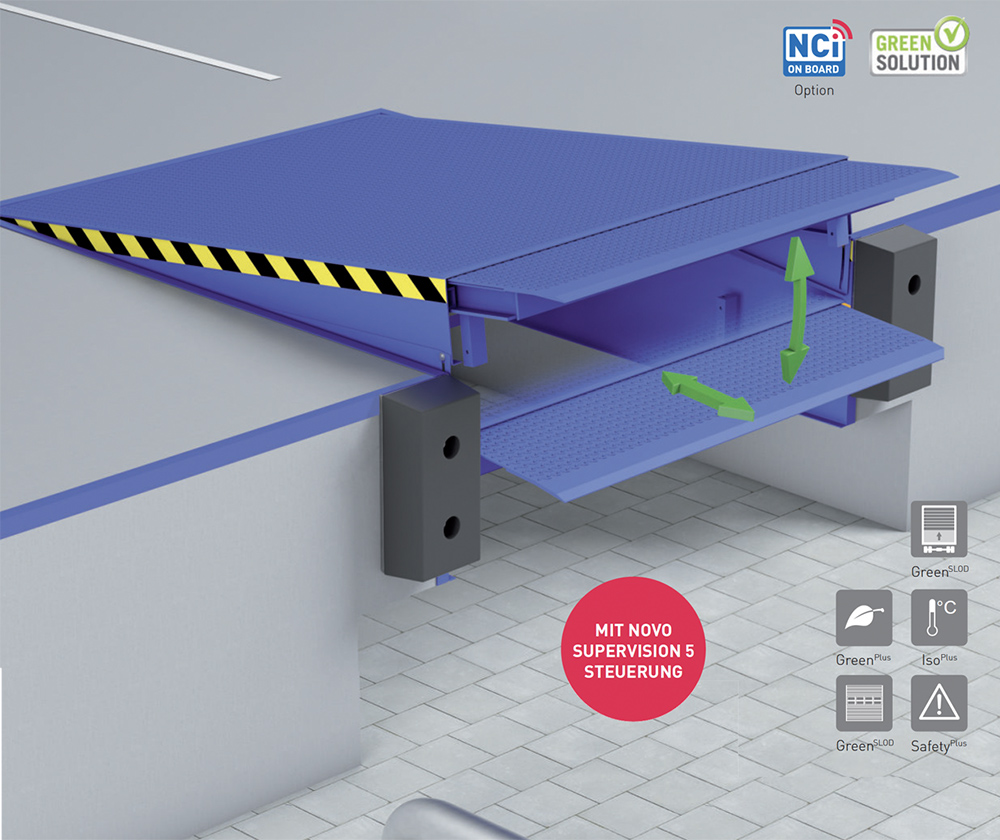

| Control system | Novo i-Vision | Novo i-Vision | Novo SuperVision 5 | Novo SuperVision 5 | Novo SuperVision 5 | Novo i-Vision | 5-button control | |

| Novo i-Vision version | ● TA | oTAD | ● TA | o TAD | o TA | o TAD | o TA | o TAD | o TA | o TAD | ● TA | o TAD | ||

| Novoferm Communication Interface (NCI) | ● | ● | o | o | o | ● | ||

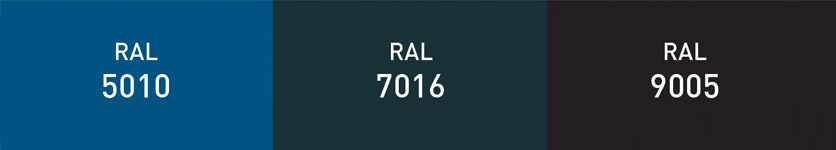

Colours | RAL 5010 (gentian blue) | ● | ● | ● | ● | ● | ● | ● |

| RAL 7016 (anthracite grey) | ● | ● | ● | ● | ● | ● | ● | |

| RAL 9005 (black) | ● | ● | ● | ● | ● | ● | ● | |

| Further RAL colours | o | o | o | o | o | o | o | |

| galvanised | o | o | o | o | o | o | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||||||||

Comparison of dock levellers with folding wedge

| Product features | L320 | L320R | L320e | P1320 | L350i | |

| with feed | ||||||

| with folding wedge | ● | ● | ● | ● | ● | |

| ISO dock | ||||||

Option packages | GreenPlus | o | o | o | o | ● |

| GreenSLOD | ||||||

| IsoPlus | o | o | o | o | ||

| DoorPlus | o | o | o | o | ||

| SafetyPlus | o | o | o | o | o | |

| Nominal load according to EN 1398 in kN | 60 | 60 | 60 | 60 | 100 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 2.750, 3.000 | 2.000, 2.500, 2.750, 3.000 | 2.000, 2.250, 2.500, 3.000 | 2.000, 2.440 (2.500), 3.000 | 2.000, 2.500, 3.000, 3.500, 4.000, 4.500 | |

| Nominal widths in mm | 2.000, 2.100, 2.250 | 1.710, 1.750, 1.960, 2.000, 2.060, 2.100, 2.160, 2.200, 2.250 | 2.000 | 2.000, 2.200, 2.250 | 1.750, 2.000, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | up to 3,000 mm (NL) | |||||

| 800 mm /830 mm2) | at 3,000 mm (NL) | |||||

| 900 mm/1200 mm3) | from 4,000 mm (NL) | |||||

| Feed/folding wedge length in mm | 400 | 400 | 400 | 400 | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | IP 65 | IP 65 | IP 65 | IP 65 | |

| Motor power in kW | max. 0.75 | max. 0.75 | max. 0.75 | max. 0.75 | max. 1.5 | |

| Design feature | Plateau of tear plate in mm | 6/8 | 6/8 | 6/8 | 6/8 | 8/10 |

| Feed/folding wedge tear plate in mm | 12/14 | 12/14 | 12/14 | 12/14 | 15/17 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 360/300 | 360/300 | 360/270 | 250/290 | |

| Nominal length 2000, overall height 700 /7251)/8302) | 360/320 | 290/340 | ||||

| Nominal length 2250, overall height 600 | 360/270 | |||||

| Nominal length 2500, overall height 600 | 380/270 | 380/270 | 330/270 | 310/270 | ||

| Nominal length 2500, overall height 700 /7251)/8302) | 380/290 | 360/330 | ||||

| Nominal length 2750, overall height 600 | 390/270 | 390/270 | ||||

| Nominal length 2750, overall height 700 | ||||||

| Nominal length 3000, overall height 600 | 400/260 | 400/260 | 270/270 | 360/270 | ||

| Nominal length 3000, overall height 700/7251)/8302) | 400/290 | 430/330 | ||||

| Nominal length 3000, overall height 800 /9002) | ||||||

| Nominal length 3500, overall height 800 | 520/350 | |||||

| Nominal length 3500, overall height 900/12003) | ||||||

| Nominal length 4000, overall height 900/12003) | 570/350 | |||||

| Nominal length 4500, overall height 900/12003) | 620/350 | |||||

| Nominal length 5000, overall height 1200 | ||||||

| Maximum permissible inclination according to EN 1398 | 12,5 % | 12,5 % | 12,5 % | 12,5 % | 12,5 % | |

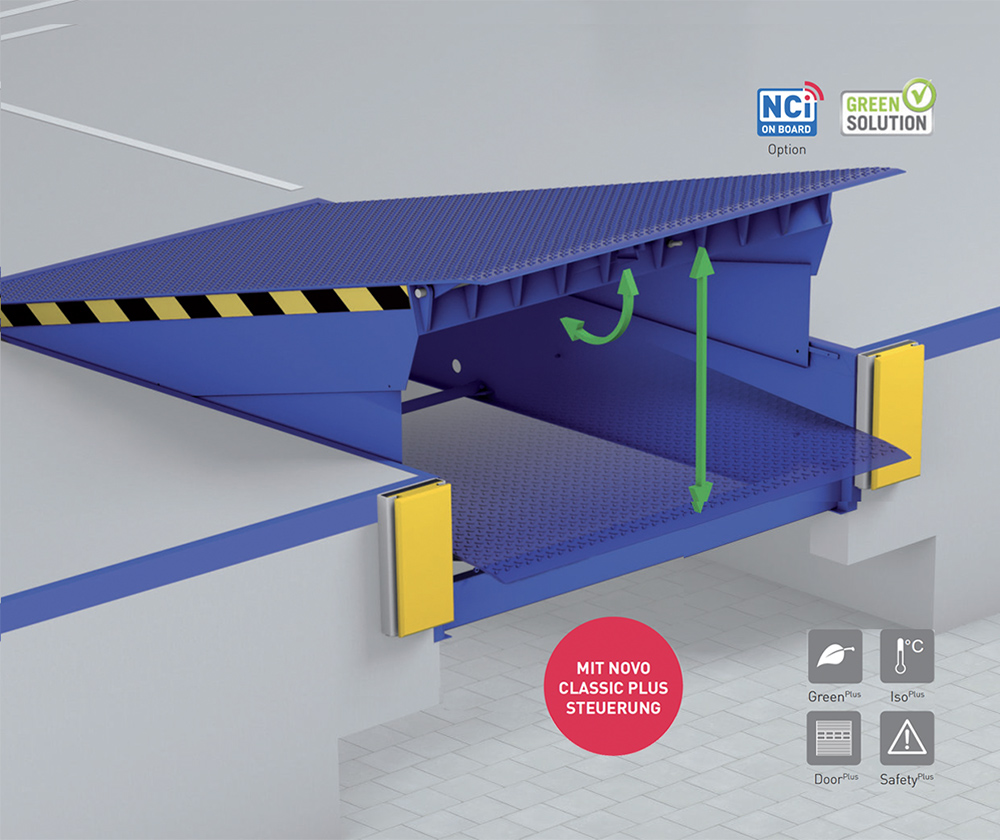

| Control system | Novo Classic Plus | Novo Classic Plus | Novo Classic Plus | Novo Classic Plus | Novo i-Vision | |

| Novo i-Vision version | o HA | o HAD | o HA | o HAD | o HA | o HAD | o HA | o HAD | ● HAR1 | |

| Novoferm Communication Interface (NCI) | o | o | o | o | ● | |

Colours | RAL 5010 (gentian blue) | ● | ● | ● | ● | ● |

| RAL 7016 (anthracite grey) | ● | ● | ● | ● | ● | |

| RAL 9005 (black) | ● | ● | ● | ● | ● | |

| Further RAL colours | o | o | o | o | o | |

| galvanised | o | o | o | o | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||||||

Details Novodock Evo x - next generation dock leveller

Details Novodock Evo x

THE NEXT GENERATION OF DOCK LEVELLERS

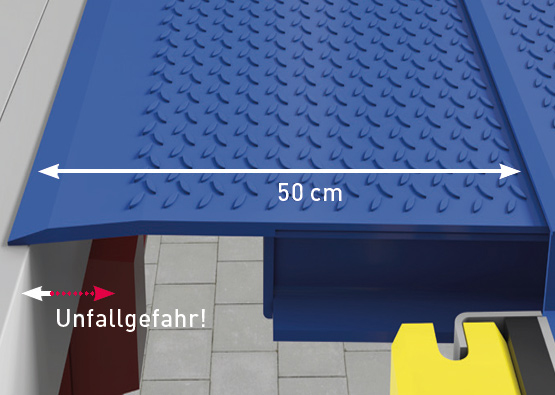

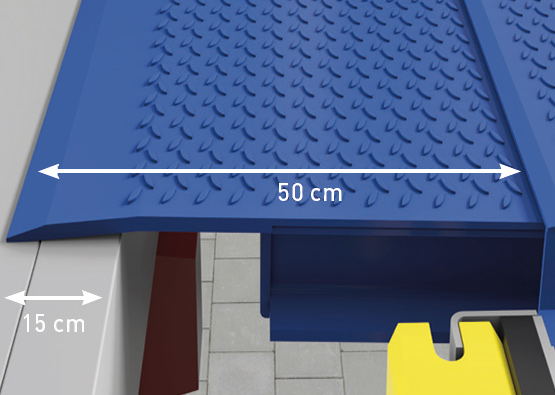

X-TRA safety

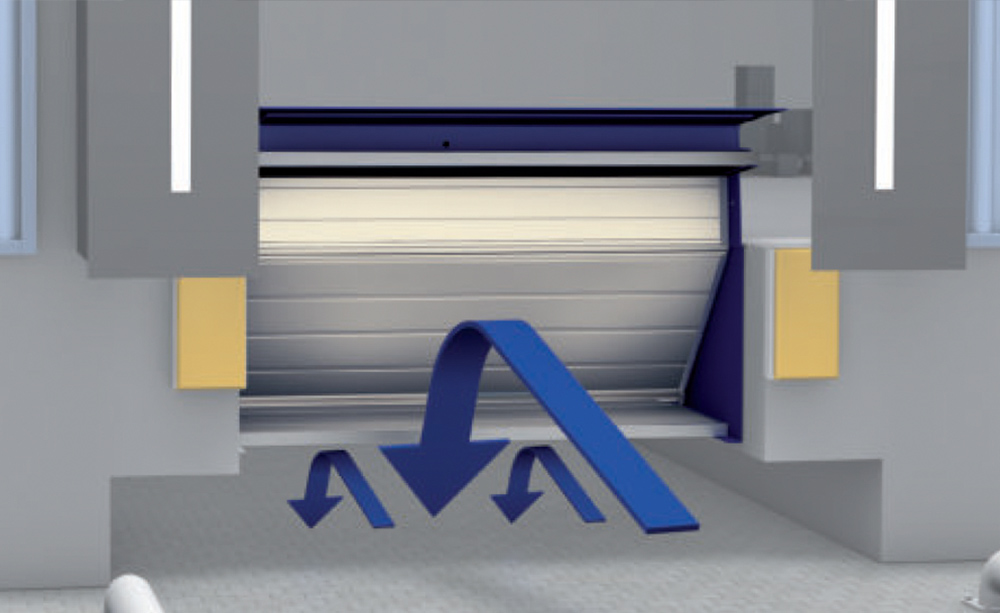

iQ-Slide - the intelligent feed follows the lorry iQ-Slide is a patented solution that automatically advances the dock leveller feed and thus follows the lorry. This prevents the feed from slipping off the lorry. If the feed has travelled its maximum distance and it is no longer possible to follow the truck, a warning signal sounds and an LED on the control unit indicates that the function is no longer active.

SLOD function - opening lorry doors safely

Thanks to the SLOD function, the operator can open the rear lorry doors without running the risk of falling off the dock leveller. A decisive safety advantage. All movements of the dock levellers with this function are carried out with just one operating button. Simple and efficient.

X-TRA Silent

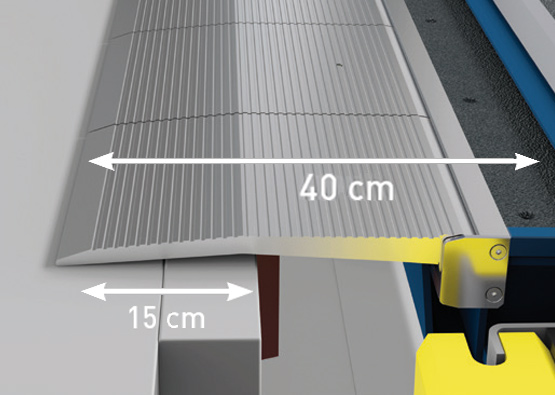

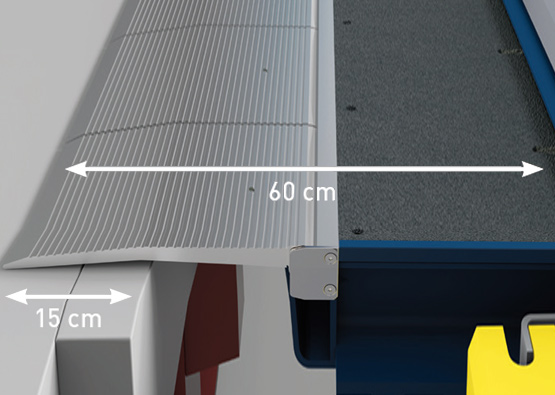

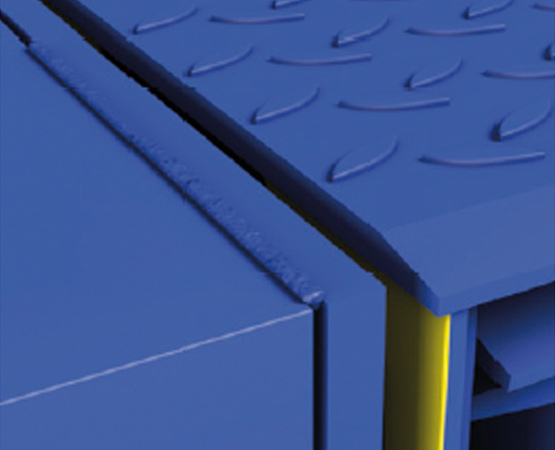

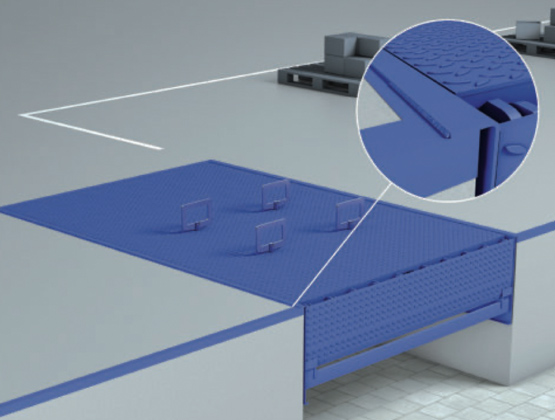

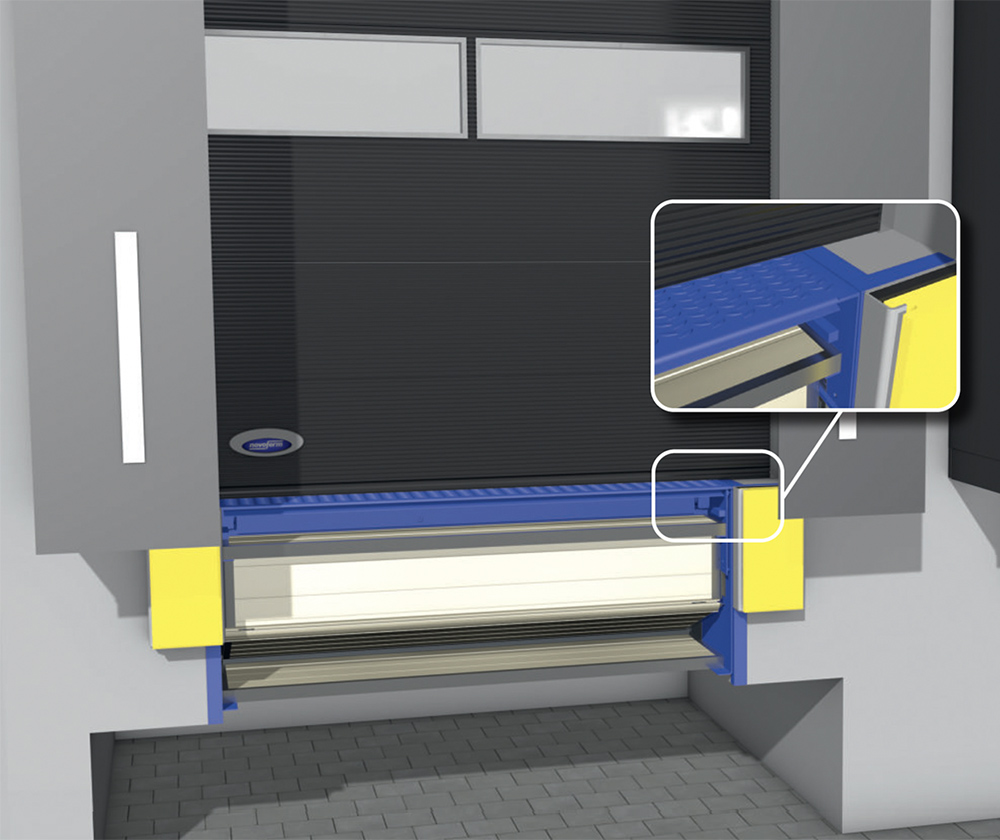

Alu-Slide - smooth transition from the truck to the dock leveller. The high-strength aluminium segments allow a smoother transition from the feed to the truck. This protects the transported goods and the forklift truck, but above all it is more ergonomic for the forklift truck driver and therefore puts less strain on his back. In addition, the noise level is considerably lower. The longer free support surface of the aluminium segments increases safety and reduces the risk of slipping off the truck.

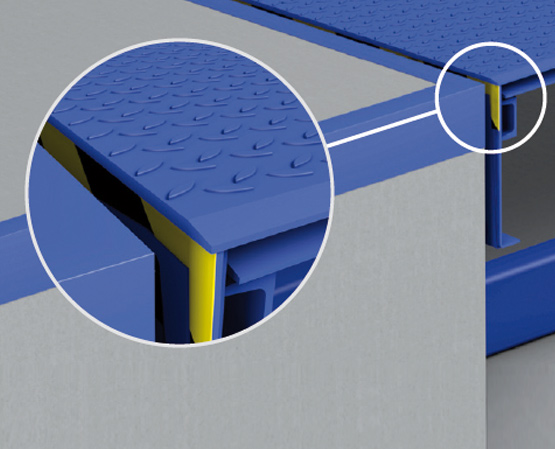

Silence Plus - like walking on silent soles

The new optional coating on the EVO X reduces noise levels by up to 85%! Independent tests (e.g. TÜV Nord) certify the enormous reduction in driving noise. The slip resistance and durability values of comparable products are also exceeded.

Product advantages | |

|

|

|

|

|

|

| |

X-TRA EFFIZIENZ

QuickDock function - Keep it simple

The quickest and easiest way to operate the dock leveller: simply press a button to attach the feed. It couldn't be quicker or easier. The QuickDock button is the only way to operate the EVO X precisely and safely. The feed is raised and extended in dead man's mode.

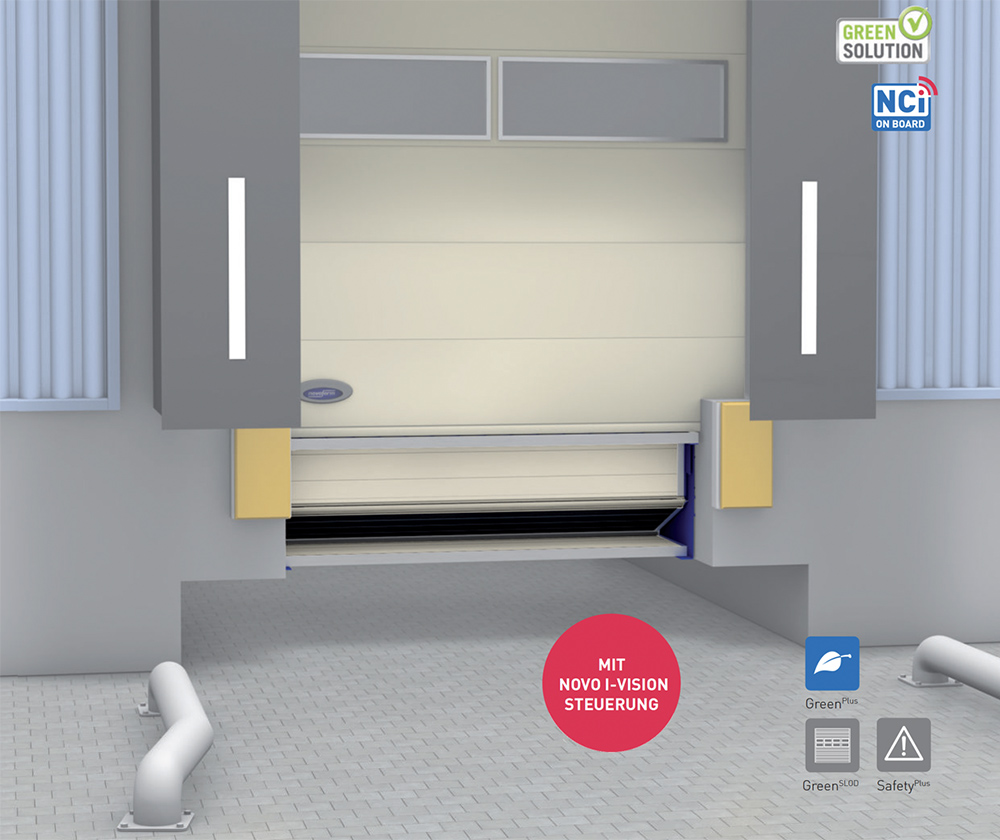

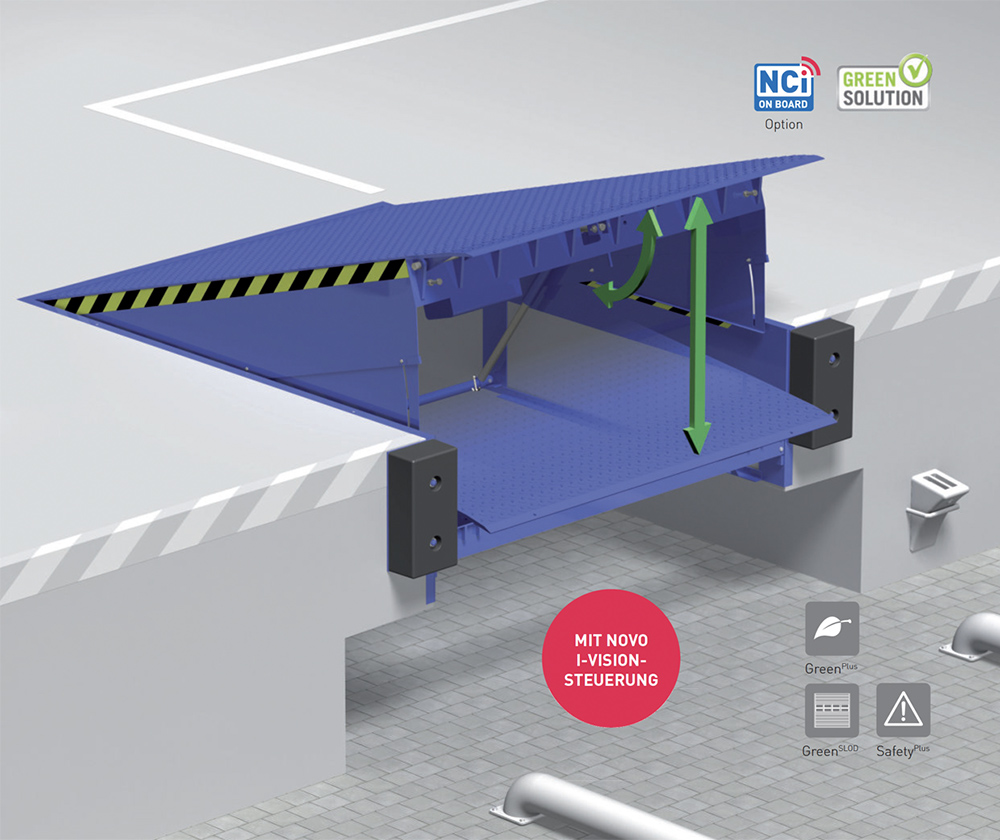

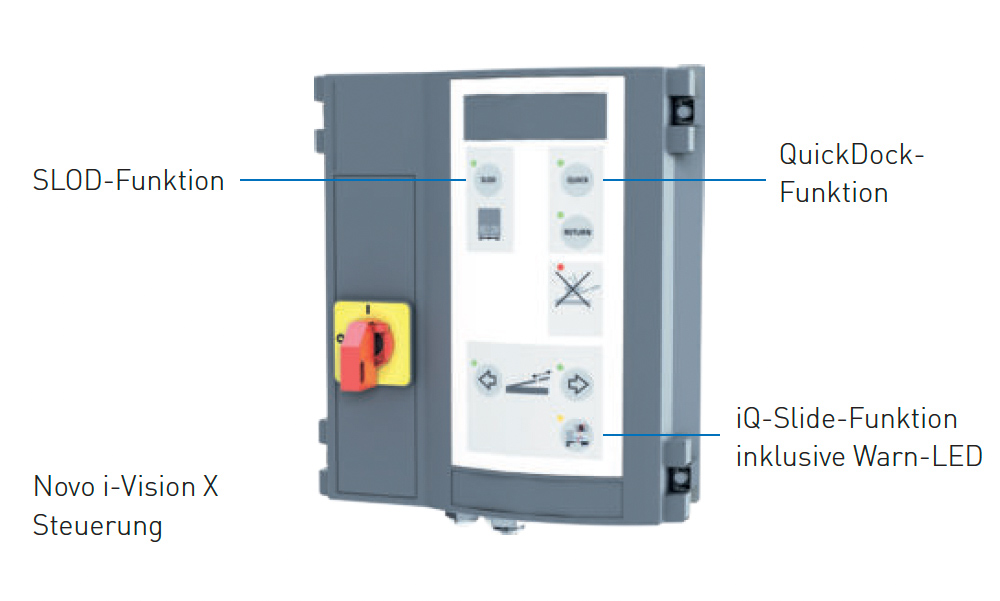

Control and operation - Novo i-Vision X

The leveller is operated using the Novo i-Vision X control unit supplied. In addition to the latest environmentally friendly technology, the control unit has unique functions such as

- Power-saving function, which results in over 70 % lower energy consumption

- User guidance via LED

- QuickDock function

- SLOD function

- iQ-Slide function incl. acoustic signal

- Maintenance interval display

- IP65 and RoHS conformity

X-TRA CONNECTIVITY

Logistics 4.0 on board

At any time, from any location, regardless of the system. Whether it's the current status, the duration of the last loading, the average frequency, the maintenance status and much more, the EVO X keeps its customers and users up to date at all times.

Top performance

Thanks to the integrated LION 4.0 docking portal with its comprehensive new options, the EVO X is becoming more efficient by the day.

THE BENCHMARK IN TERMS OF SAFETY, EFFICIENCY AND CONNECTIVITY

EVO X dock leveller with iQ-Slide principle

- The intelligent feed follows the lorry

- The loading situation is safe

Standard dock leveller without iQ-Slide principle

- Standard feed without warning

- The loading situation is critical.

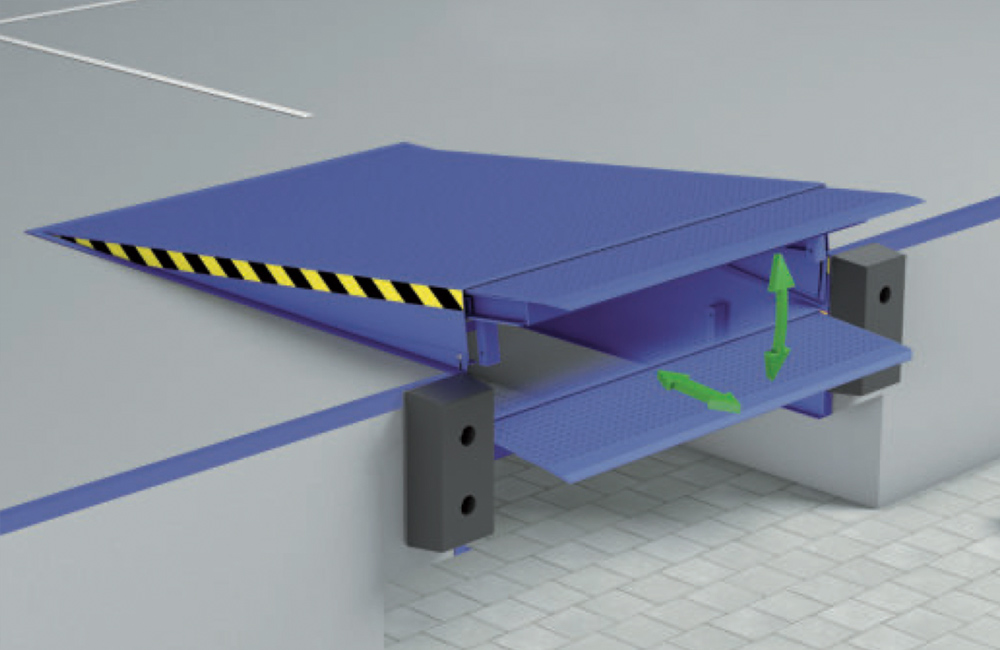

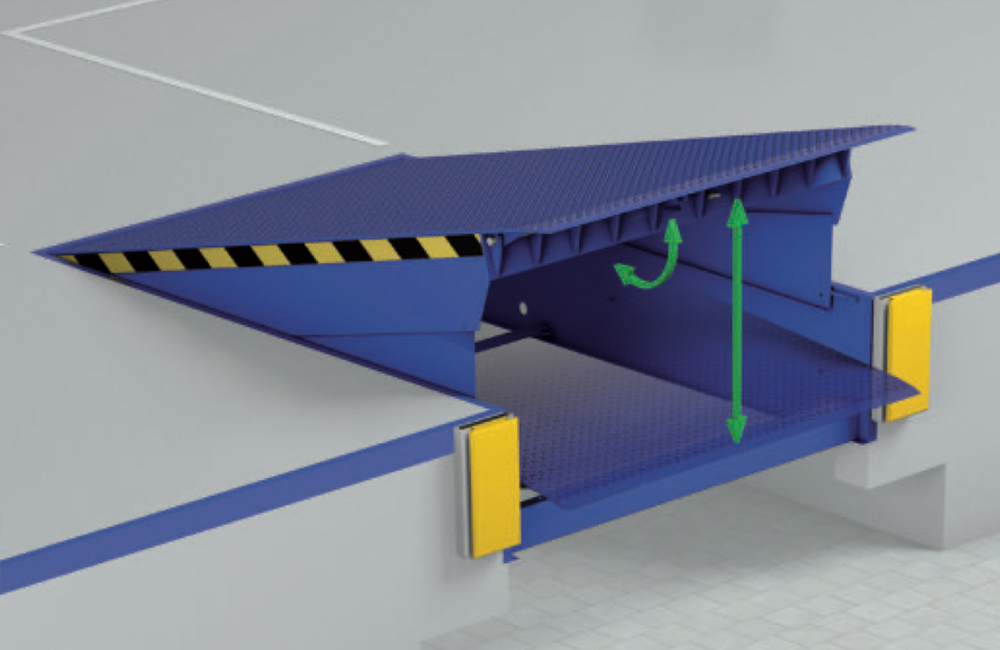

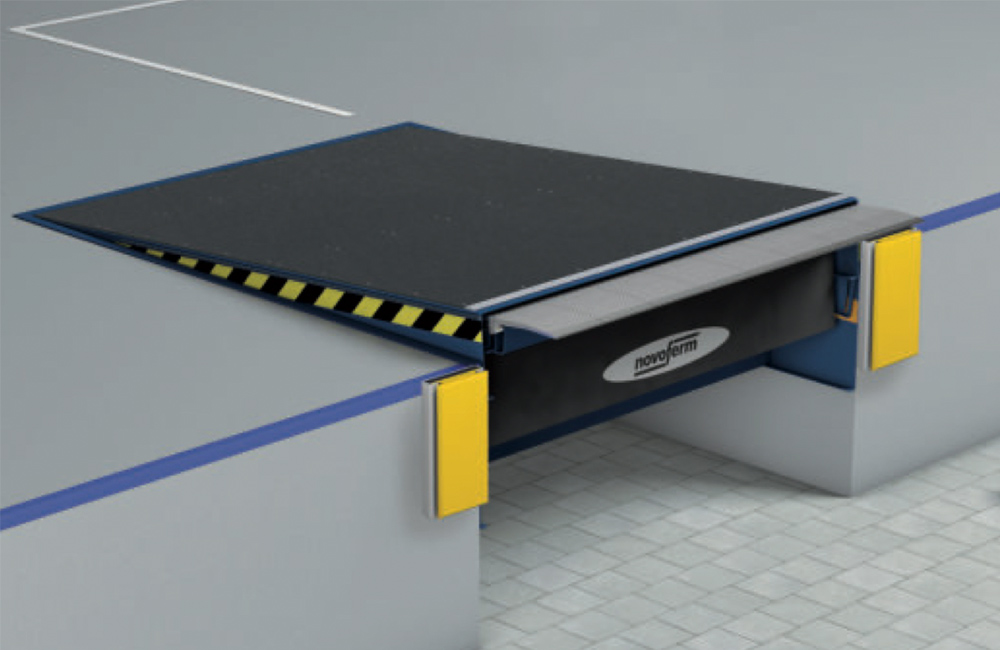

Details Novodock L730i - Ideal ISO loading point

Details Novodock L730i

Product benefits | |

|

|

|

|

|

|

|

|

|

|

Not just for refrigerated warehouses

No other loading solution offers all these benefits in one package. The rising energy costs combined with the attractive price make this intelligent solution interesting for any heated or refrigerated warehouse.

Sustainability and energy saving

The standard GreenPLUS package ensures the use of recyclable materials. Thanks to an energy-saving function, the L730i saves up to 70 % of energy costs compared to conventional solutions and makes an important contribution toreducing CO2 emissions.

Increased efficiency through automation

The DoorPLUS package controls the dock leveller, the electrically driven sectional door, an inflatable door seal and possible equipment such as traffic lights and loading lights in just one housing. In conjunction with the LED user guidance, incorrect operation is impossible and damage is avoided. The AutoDock function safely returns all connected products to the idle position, thereby increasing efficiency.

The future is already on board

The integrated Novoferm Communication Interface (NCI) provides over 50 important parameters. With the LION 4.0 software, you can analyse the data for efficient loading.

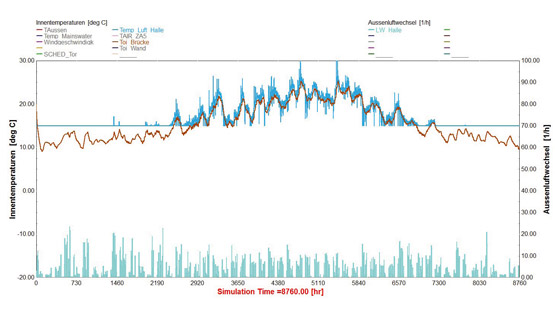

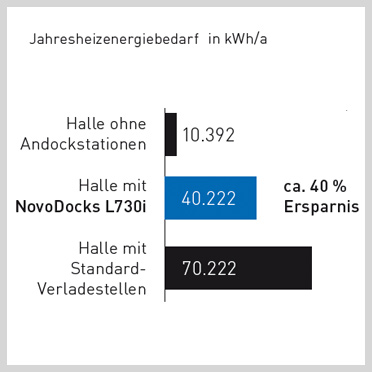

STUDY PROVES ENORMOUS ENERGY SAVINGS

The heating energy requirement is reduced by 40 %.

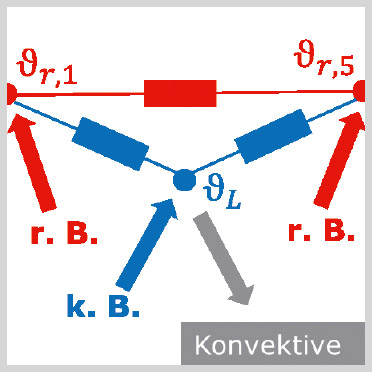

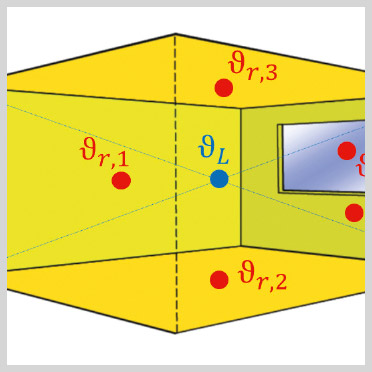

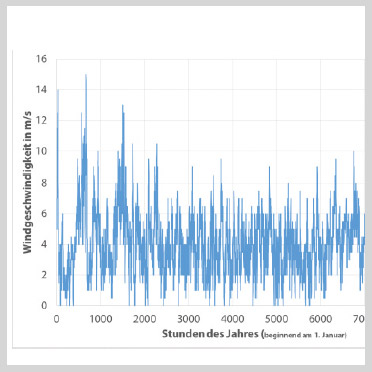

Thermal building and air flow models are generated under realistic conditions by linking the tried-and-tested TRNSYS and TRNFLOW software programmes. The study verifiably determines the thermal behaviour of logistics halls and the energy efficiency of loading bridge encapsulation.

The following assumptions were made for the calculation:

- Logistics hall, current standard, room temperature 15 °C

- 4 loads per loading point per day, 5 days a week

- in 75 % of cases, loading takes place simultaneously on both sides

- average duration of loading: 30 min

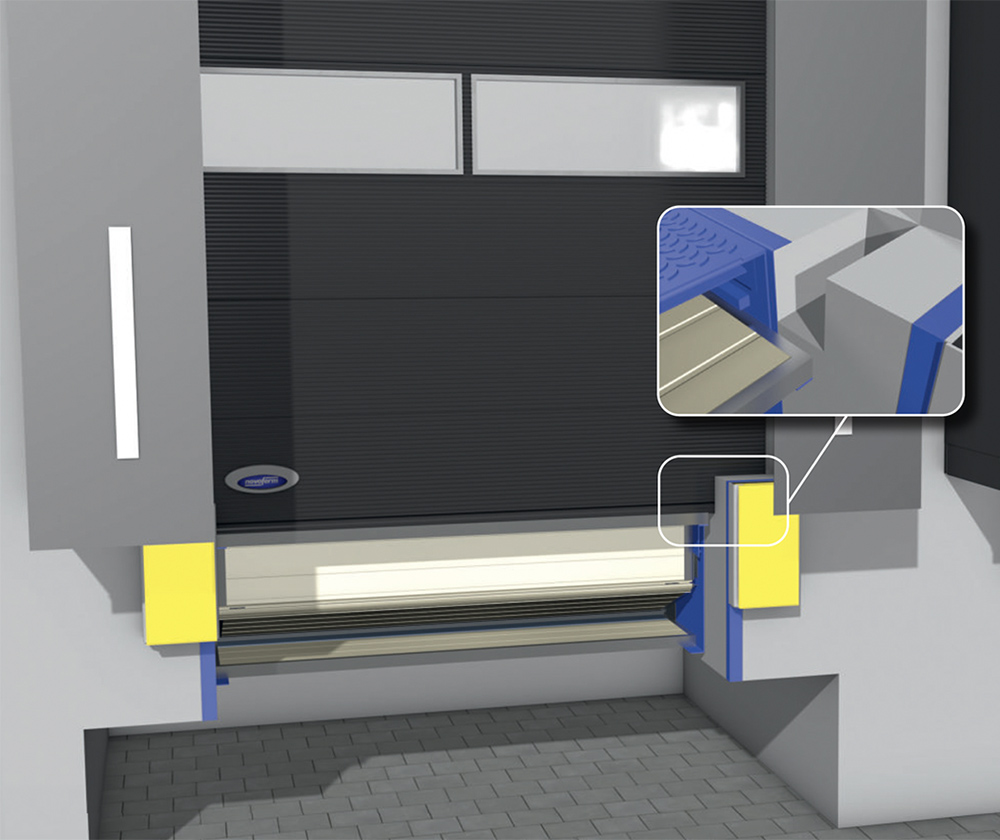

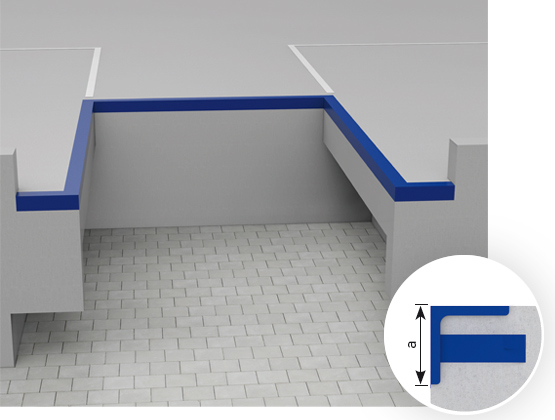

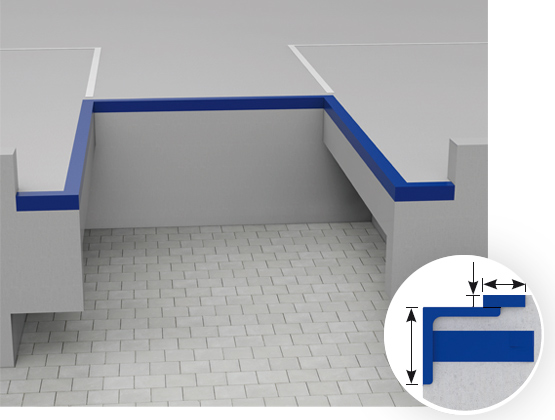

DIE IDEALE ISO-VERLADESTELLE

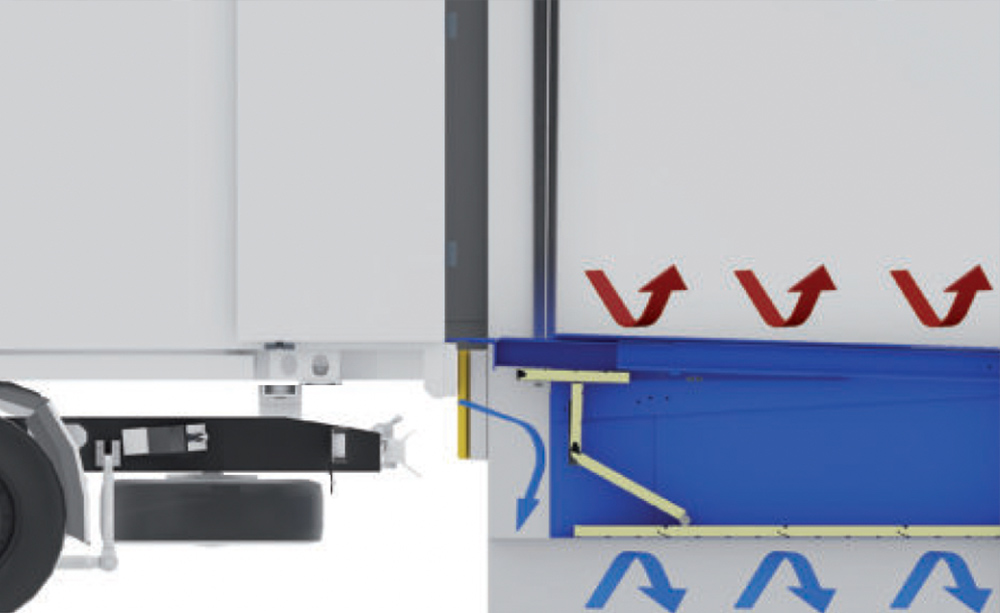

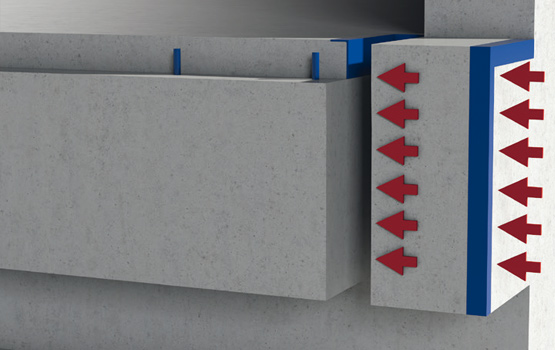

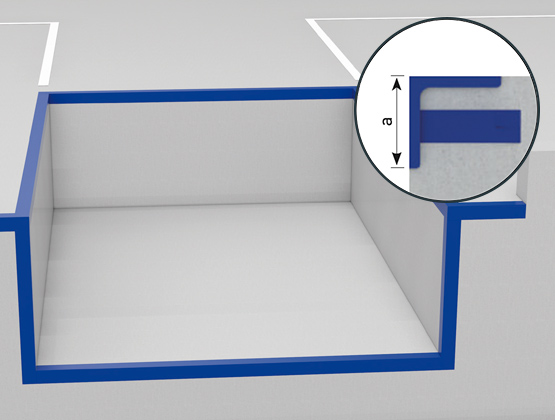

The unique design of the NovoDock L730i ensures the best possible insulation of the loading point at all times. Even during loading, no draughts get under the dock leveller, thus avoiding a cold bridge.

FOR TEMPERATURE-CONTROLLED WAREHOUSES

The illustration shows a typical loading situation with the NovoDock L730i. The exchange of different temperature conditions is avoided. The weather remains outside and the temperature in the hall remains almost constant.

ADVANTAGES OVER A CONVENTIONAL ISO LOADING BAY

| Features | NovoDock L730i | Conventional ISO loading point |

| Pit preparation | simple | complex |

| Can be driven under | possible at any time | Only possible when the door is open |

| Insulation during loading | possible at any time | not given |

| GreenPLUS package | up to 70 % lower energy consumption | not available |

| DoorPLUS package | Door, dock leveller, TAD and equipment are controlled via only one control unit | not available, various controls required |

| Approach forces | are fed directly into the base plate | complex, solid frost apron required |

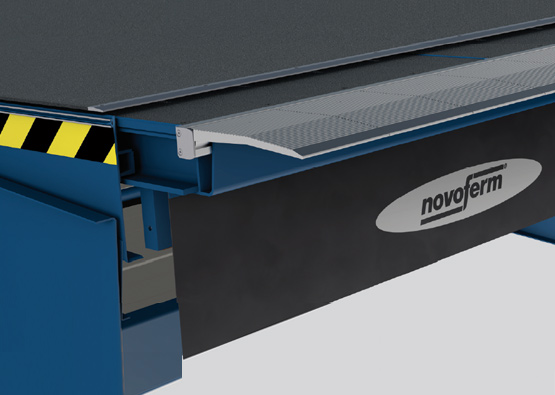

Details NovoDock L530 with feed

Details NovoDock L530

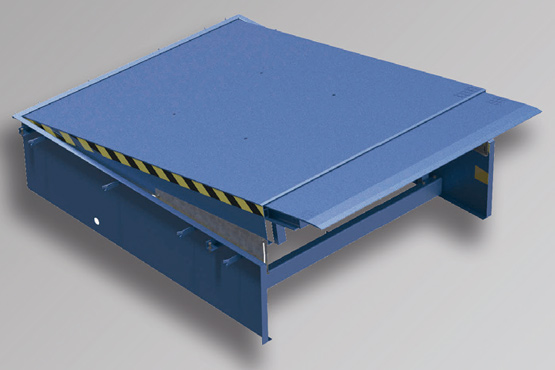

HYDRAULIC DOCK LEVELLER WITH FEED FOR THE HIGHEST REQUIREMENTS

The NovoDock L530 is optimised for the increased market requirements and combines the advantages of different systems. The hydraulic dock leveller with feed is particularly robust and enables efficient loading thanks to state-of-the-art control technology.

The new NovoSmart Drive drive system ensures the simplest and most efficient operation with the lowest energy consumption.

Product advantages | |

|

|

|

|

|

|

|

|

Details Novodock L530R with feed

Details Novodock L530R

HYDRAULIC DOCK LEVELLER WITH FEED AS A REPLACEMENT SOLUTION

The NovoDock L530R is specially designed as a replacement solution and combines the advantages of different systems. The hydraulic dock leveller with feed is particularly robust and enables efficient loading thanks to state-of-the-art control technology. The new NovoSmart Drive drive system ensures the simplest and most efficient operation with the lowest energy consumption.

Product advantages | |

|

|

|

|

|

|

|

|

Details Novodock L550i with feed

Details Novodock L550i

HYDRAULIC LEVELLER WITH FEED

The NovoDock L550i is specially designed for heavier goods. The hydraulic dock leveller with feed combines robust steel construction with state-of-the-art control technology, thus enabling efficient loading. As with all products with the GreenPlus package, materials are used that fulfil current environmental standards and make an important contribution to reducing CO2 emissions with extremely low energy requirements.

Product benefits | |

|

|

|

|

|

|

|

|

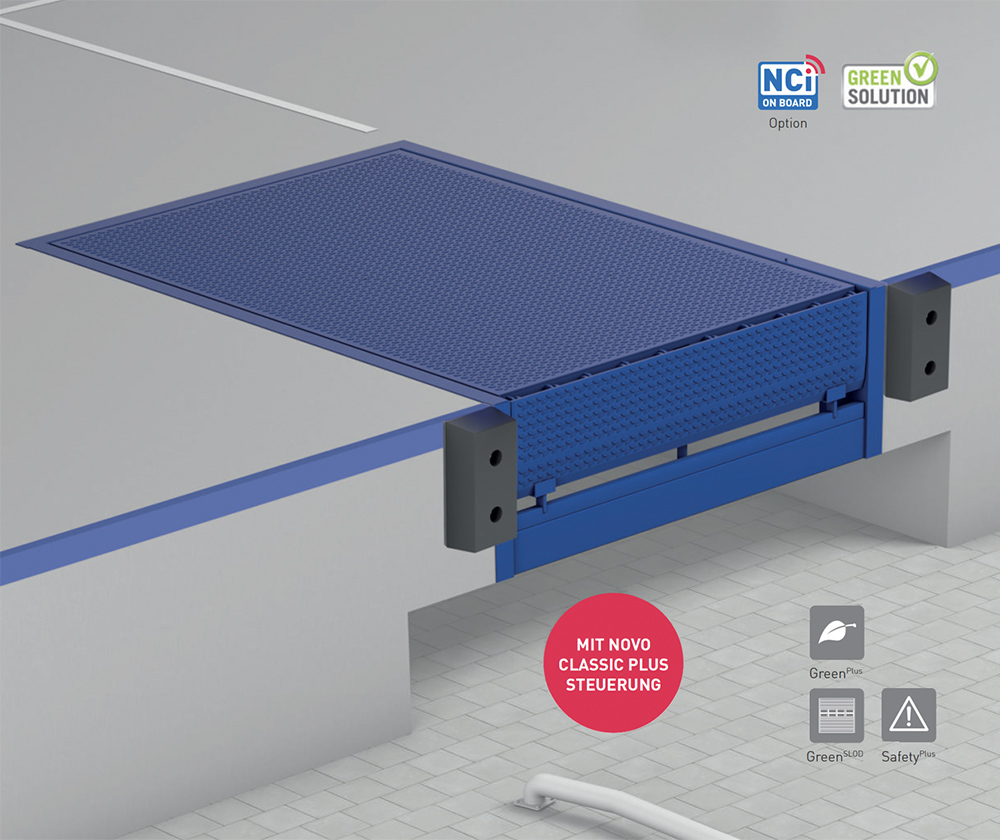

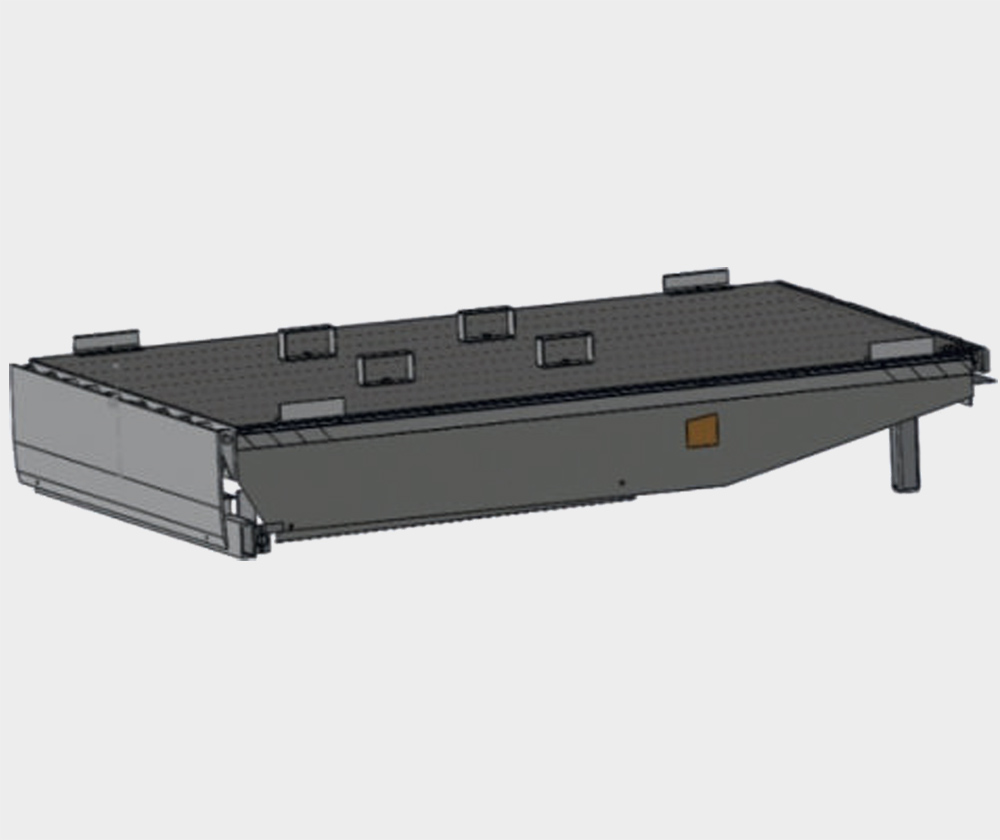

Details Novodock P1530 with feed

Details Novodock P1530

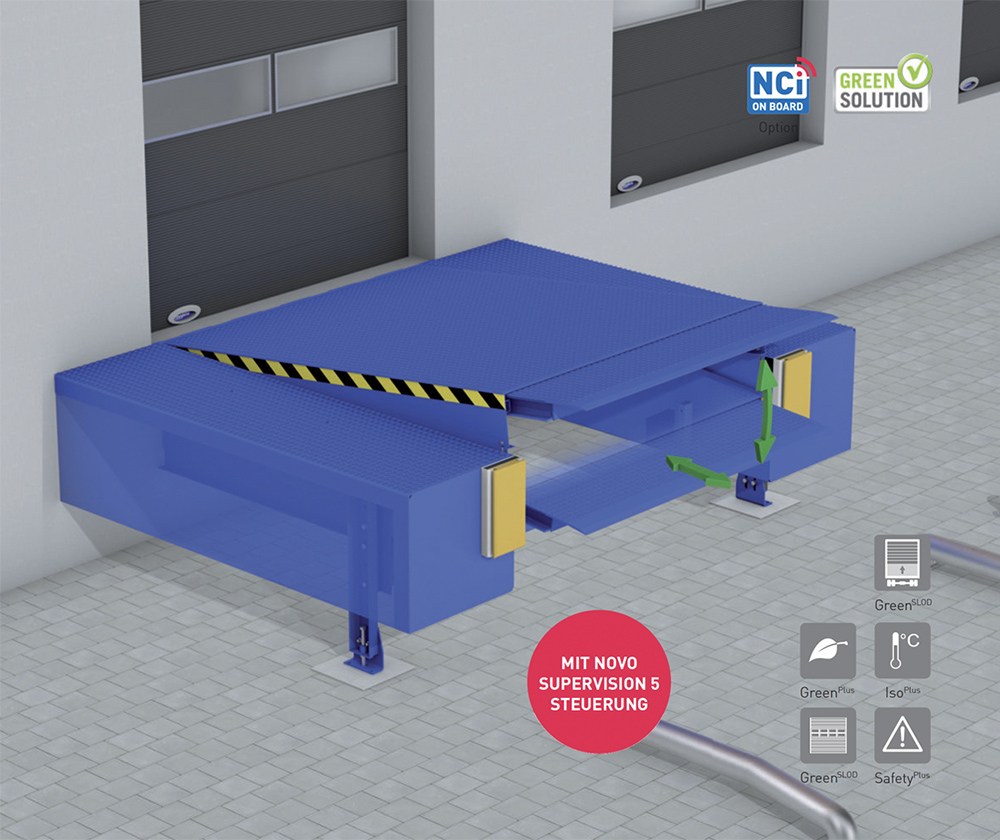

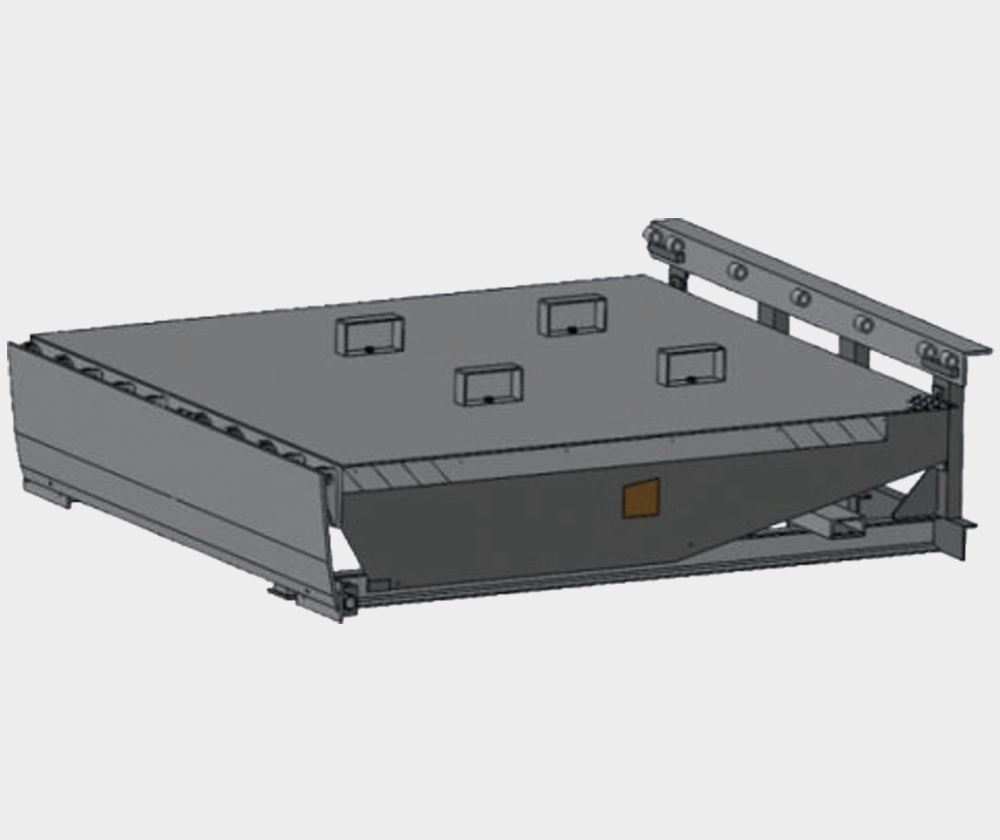

HYDRAULIC DOCK LEVELLER WITH FEED IN STEEL FRAME

Thanks to the steel frame, the NovoDock P1530 can be installed in front of the building and also serve as the basis for a loading chute. The hydraulic dock leveller with feed is particularly robust and enables efficient loading thanks to state-of-the-art control technology. The new NovoSmart Drive drive system ensures the simplest and most efficient operation with the lowest energy consumption.

Product benefits | |

|

|

|

|

|

|

Details Novodock VL6020 with feed

Details Novodock VL6020

The NovoDock VL6020 is designed for flexible user requirements. In addition to the advantages of a normal dock leveller with state-of-the-art controls and hydraulics, the design also offers the option of loading and unloading vans. Everything at one loading station.

The dock leveller is operated using the 5-button control supplied. Lorries are loaded in the normal position. The control can be switched to transporter mode with a dynamic load capacity of 20 kN. In this mode, only the 1200 mm wide centre feed is extended and only a very small amount of force (maximum 50 kg) is transferred to the van.

Product advantages | |

|

|

| |

Details NovoDock L320 with folding wedge

Details NovoDock L320

Hydraulic dock levellers with folding wedge have proven themselves in loading technology established as the basic version in loading technology. The NovoDock L320 redefines this standard. It combines many years of experience and a robust steel construction with a new design and state-of-the-art control technology. It goes without saying that only materials that comply with current environmental standards are used.

Product advantages | |

|

|

|

|

|

|

Details Novodock L320R with folding wedge

Details Novodock L320R

HYDRAULIC DOCK LEVELLER WITH FOLDING WEDGE AS REPLACEMENT SOLUTION

Hydraulic dock levellers with a folding wedge have established themselves as the basic version in loading technology. The Novo-Dock L320R is specially designed for replacing existing dock levellers. It combines many years of experience and a robust steel construction with a new design and state-of-the-art control technology.

Product advantages | |

|

|

|

|

Details Novodock L320e with folding wedge

Details Novodock L320e

TRANSPORT-OPTIMISED DOCK LEVELLER WITH FOLDING WEDGE

Hydraulic dock levellers with a folding wedge have established themselves as the basic version in loading technology. The L320e redefines this standard. It is transport-optimised and available in two versions.

While the NovoDock L320e ECO is only prepared with a rear frame, the NovoDock L320e ECOPlus includes a transport-optimised pit frame. Both versions require special pit preparation.

Up to 30 NovoDock L320e units can be transported on a lorry or in a container.

Product advantages | |

|

|

|

|

| |

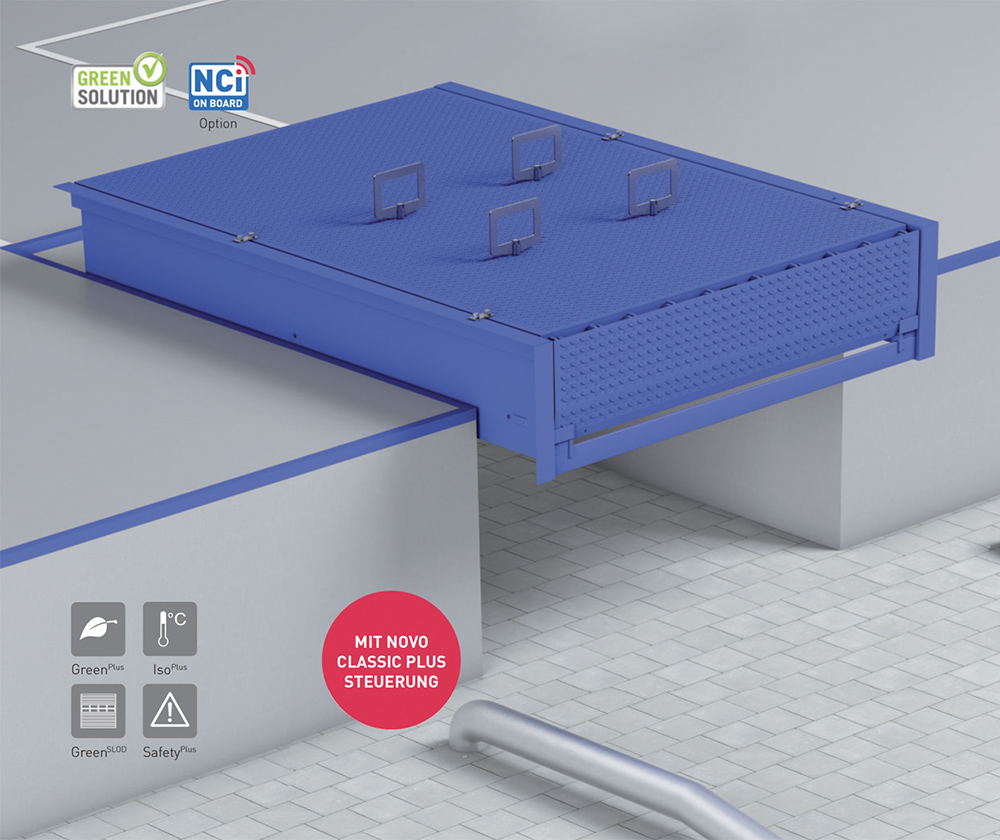

Details NovoDock P1320 with folding wedge

Details NovoDock P1320

HYDRAULIC DOCK LEVELLERS WITH FOLDING WEDGE IN STEEL FRAME

Thanks to the steel frame, the NovoDock P1320 can be installed in front of the building and also serve as a base for a loading lock. With the integrated Novo Classic Plus control system, the dock leveller is easy and safe to operate. The NCI is available as an option for the NovoDock P1320.

Product benefits | |

|

|

|

|

| |

Details Novodock L350I with folding wedge

Details Novodock L350I

HYDRAULIC DOCK LEVELLER WITH FOLDING WEDGE AND HIGHER LOAD CAPACITY

The NovoDock L350i with folding wedge is operated conveniently and safely using the integrated Novo i-Vision HA control unit. Like all Green Solution products, the NovoDock L350i also ensures a reduction in CO2 and savings in operating costs thanks to optimised energy requirements. The stable steel construction remains unchanged and the NCI provides the decisive advantage over all other dock levellers on the market with a folding wedge.

Product benefits | |

|

|

|

|

|

|

| |

Technology and details

Technical data Novodock L730I

Technical data

| Product features | L730i ISO | L730i Standard | |

| with feed | ● | ● | |

| with folding wedge | |||

| ISO dock | ● | ● | |

Option packages | GreenPlus | ● | ● |

| GreenSLOD | |||

| IsoPlus | |||

| DoorPlus | o | o | |

| SafetyPlus | o | o | |

| Nominal load according to EN 1398 in kN | 60 | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 3.000 | 2.000, 2.500, 3.000 | |

| Nominal widths in mm | 2.000, 2.250 | 2.000, 2.250 | |

Overall height | 600 mm | ||

| 700 mm/725 mm1) | |||

| 800 mm /830 mm2) | up to 3,000 mm (NL) | up to 3,000 mm (NL) | |

| 900 mm/1200 mm3) | at 3,000 mm (NL) | at 3,000 mm (NL) | |

| Feed/folding wedge length in mm | ● 700 / o 1.000 | ● 500 / o 700 / o 1,000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | IP 65 | |

| Motor power in kW | max. 1.5 | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 | 8/10 |

| Feed/folding wedge liner plate in mm | 12/14 | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | ||

| Nominal length 2000, overall height 700 /7251)/8302) | 350 (400)/370 (400) | 320/3404) | |

| Nominal length 2250, overall height 600 | |||

| Nominal length 2500, overall height 600 | |||

| Nominal length 2500, overall height 700 /7251)/8302) | 400 (430)/370 (370) | 370/3104) | |

| Nominal length 2750, overall height 600 | |||

| Nominal length 2750, overall height 700 | |||

| Nominal length 3000, overall height 600 | |||

| Nominal length 3000, overall height 700/7251)/8302) | 340 (370)/330 (350) | 310/3104) | |

| Nominal length 3000, overall height 800 /9002) | 400 (430)/370 (400) | 370/3504) | |

| Nominal length 3500, overall height 800 | |||

| Nominal length 3500, overall height 900/12003) | |||

| Nominal length 4000, overall height 900/12003) | |||

| Nominal length 4500, overall height 900/12003) | |||

| Nominal length 5000, overall height 1200 | |||

| Maximum permissible inclination according to EN 1398 | 12,5 % | 12,5 % | |

| Control system | Novo i-Vision | Novo i-Vision | |

| Novo i-Vision version | ● TA | oTAD | ● TA | o TAD | |

| Novoferm Communication Interface (NCI) | ● | ● | |

Colours | RAL 5010 (gentian blue) | ● | ● |

| RAL 7016 (anthracite grey) | ● | ● | |

| RAL 9005 (black) | ● | ● | |

| Other RAL colours | o | o | |

| galvanised | o | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | |||

Technical data NovoDock L530

| Product features | L530 | |

| with feed | ● | |

| with folding wedge | ||

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | o | |

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 3.000 | |

| Nominal widths in mm | 1.750, 2.000, 2.250, 2.400 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | up to 3,000 mm (NL) | |

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | ● 500 / o 1.000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 330 (405)/300 (315) |

| Nominal length 2000, overall height 700 /7251)/8302) | 360 (440)/400 (435) | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | 430 (500)/290 (280) | |

| Nominal length 2500, overall height 700 /7251)/8302) | 470 (540)/370 (390) | |

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | 420 (475)/270 (260) | |

| Nominal length 3000, overall height 700/7251)/8302) | 480 (565)/400 (390) | |

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo SuperVision 5 | |

| Novo i-Vision version | o TA | o TAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock L530R

| Product features | L530R | |

| with feed | ● | |

| with folding wedge | ||

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | o | |

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 2.750, 3.000 | |

| Nominal widths in mm | 1.710, 1.750, 1.960, 2.000, 2.060, 2.100, 2.160, 2.200, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | up to 3,000 mm (NL) | |

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | ● 500 / o 1.000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 330 (405)/300 (315) |

| Nominal length 2000, overall height 700 /7251)/8302) | 360 (440)/400 (435) | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | 430 (500)/290 (280) | |

| Nominal length 2500, overall height 700 /7251)/8302) | 470 (540)/370 (390) | |

| Nominal length 2750, overall height 600 | 400 (500)/270 (270) | |

| Nominal length 2750, overall height 700 | 430 (530)/350 (370) | |

| Nominal length 3000, overall height 600 | 420 (475)/270 (260) | |

| Nominal length 3000, overall height 700/7251)/8302) | 480 (565)/400 (390) | |

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo SuperVision 5 | |

| Novo i-Vision version | o TA | o TAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock L550I

| Product features | L550i | |

| with feed | ● | |

| with folding wedge | ||

| ISO dock | ||

Option packages | GreenPlus | ● |

| GreenSLOD | ||

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 100 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 3.000, 3.500, 4.000, 4.500 | |

| Nominal widths in mm | 2.000, 2.250, 2.400 | |

Overall height | 600 mm | |

| 700 mm/725 mm1) | up to 2,500 mm (NL) | |

| 800 mm /830 mm2) | at 3,000 mm (NL) | |

| 900 mm/1200 mm3) | from 3,500 mm (NL) | |

| Feed/folding wedge length in mm | 500 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 10/12 |

| Feed/folding wedge liner plate in mm | 15/17 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | |

| Nominal length 2000, overall height 700 /7251)/8302) | 300/400 | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | ||

| Nominal length 2500, overall height 700 /7251)/8302) | 300/400 | |

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | ||

| Nominal length 3000, overall height 700/7251)/8302) | ||

| Nominal length 3000, overall height 800 /9002) | 370/400 | |

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | 450/400 | |

| Nominal length 4000, overall height 900/12003) | 450/400 | |

| Nominal length 4500, overall height 900/12003) | 450/400 | |

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo i-Vision | |

| Novo i-Vision version | TA | o TAD | |

| Novoferm Communication Interface (NCI) | ● | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock P1530

| Product features | P1530 | |

| with feed | ● | |

| with folding wedge | ||

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | o | |

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.440 (2.500), 3.000 | |

| Nominal widths in mm | 2.000, 2.200, 2.250 | |

Overall height | 600 mm | |

| 700 mm/725 mm1) | up to 3,000 mm (NL) | |

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | ● 500 / o 1.000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | |

| Nominal length 2000, overall height 700 /7251)/8302) | 360 (460)/380 (430) | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | ||

| Nominal length 2500, overall height 700 /7251)/8302) | 470 (590)/350 (390) | |

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | ||

| Nominal length 3000, overall height 700/7251)/8302) | 480 (590)/400 (380) | |

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo SuperVision 5 | |

| Novo i-Vision version | o TA | o TAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock VL6020

| Product features | VL6020 | |

| with feed | ● | |

| with folding wedge | ||

| ISO dock | ||

Option packages | GreenPlus | |

| GreenSLOD | ||

| IsoPlus | ||

| DoorPlus | ||

| SafetyPlus | ||

| Nominal load according to EN 1398 in kN | 60/20 | |

| Nominal lengths (NL) in mm | 3.500, 4.000, 4.500, 5.000 | |

| Nominal widths in mm | 2.000 | |

Overall height | 600 mm | |

| 700 mm/725 mm1) | ||

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | up to 5,000 mm (NL) | |

| Feed/folding wedge length in mm | ● 500 / o 1.000 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 54 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 |

| Feed/folding wedge liner plate in mm | 15/17 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | |

| Nominal length 2000, overall height 700 /7251)/8302) | ||

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | ||

| Nominal length 2500, overall height 700 /7251)/8302) | ||

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | ||

| Nominal length 3000, overall height 700/7251)/8302) | ||

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | 400/600 | |

| Nominal length 4000, overall height 900/12003) | 400/650 | |

| Nominal length 4500, overall height 900/12003) | 400/750 | |

| Nominal length 5000, overall height 1200 | 400/775 | |

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | 5-button control | |

| Novo i-Vision version | ||

| Novoferm Communication Interface (NCI) | ||

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock L320

| Product features | L320 | |

| with feed | ||

| with folding wedge | ● | |

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | ||

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 2.750, 3.000 | |

| Nominal widths in mm | 2.000, 2.100, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | ||

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 0.75 | |

| Design feature | Plateau louvre plate in mm | 6/8 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 360/300 |

| Nominal length 2000, overall height 700 /7251)/8302) | ||

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | 380/270 | |

| Nominal length 2500, overall height 700 /7251)/8302) | ||

| Nominal length 2750, overall height 600 | 390/270 | |

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | 400/260 | |

| Nominal length 3000, overall height 700/7251)/8302) | ||

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo Classic Plus | |

| Novo i-Vision version | o HA | o HAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock L320R

| Product features | L320R | |

| with feed | ||

| with folding wedge | ● | |

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | ||

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 2.750, 3.000 | |

| Nominal widths in mm | 1.710, 1.750, 1.960, 2.000, 2.060, 2.100, 2.160, 2.200, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | ||

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 0.75 | |

| Design feature | Plateau louvre plate in mm | 6/8 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 360/300 |

| Nominal length 2000, overall height 700 /7251)/8302) | ||

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | 380/270 | |

| Nominal length 2500, overall height 700 /7251)/8302) | ||

| Nominal length 2750, overall height 600 | 390/270 | |

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | 400/260 | |

| Nominal length 3000, overall height 700/7251)/8302) | ||

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo Classic Plus | |

| Novo i-Vision version | o HA | o HAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data Novodock L320E

| Product features | L320e | |

| with feed | ||

| with folding wedge | ● | |

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | ||

| IsoPlus | ||

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.250, 2.500, 3.000 | |

| Nominal widths in mm | 2.000 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | ||

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 0.75 | |

| Design feature | Plateau louvre plate in mm | 6/8 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 360/270 |

| Nominal length 2000, overall height 700 /7251)/8302) | ||

| Nominal length 2250, overall height 600 | 360/270 | |

| Nominal length 2500, overall height 600 | 330/270 | |

| Nominal length 2500, overall height 700 /7251)/8302) | ||

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | 270/270 | |

| Nominal length 3000, overall height 700/7251)/8302) | ||

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo Classic Plus | |

| Novo i-Vision version | o HA | o HAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock P1320

| Product features | P1320 | |

| with feed | ||

| with folding wedge | ● | |

| ISO dock | ||

Option packages | GreenPlus | o |

| GreenSLOD | ||

| IsoPlus | o | |

| DoorPlus | o | |

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 60 | |

| Nominal lengths (NL) in mm | 2.000, 2.440 (2.500), 3.000 | |

| Nominal widths in mm | 2.000, 2.200, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | ||

| 800 mm /830 mm2) | ||

| 900 mm/1200 mm3) | ||

| Feed/folding wedge length in mm | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 0.75 | |

| Design feature | Plateau louvre plate in mm | 6/8 |

| Feed/folding wedge liner plate in mm | 12/14 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | |

| Nominal length 2000, overall height 700 /7251)/8302) | 360/320 | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | ||

| Nominal length 2500, overall height 700 /7251)/8302) | 380/290 | |

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | ||

| Nominal length 3000, overall height 700/7251)/8302) | 400/290 | |

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | ||

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | ||

| Nominal length 4500, overall height 900/12003) | ||

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo Classic Plus | |

| Novo i-Vision version | o HA | o HAD | |

| Novoferm Communication Interface (NCI) | o | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Technical data NovoDock L350i

| Product features | L350i | |

| with feed | ||

| with folding wedge | ● | |

| ISO dock | ||

Option packages | GreenPlus | ● |

| GreenSLOD | ||

| IsoPlus | o | |

| DoorPlus | ||

| SafetyPlus | o | |

| Nominal load according to EN 1398 in kN | 100 | |

| Nominal lengths (NL) in mm | 2.000, 2.500, 3.000, 3.500, 4.000, 4.500 | |

| Nominal widths in mm | 1.750, 2.000, 2.250 | |

Overall height | 600 mm | up to 3,000 mm (NL) |

| 700 mm/725 mm1) | up to 3,000 mm (NL) | |

| 800 mm /830 mm2) | at 3,000 mm (NL) | |

| 900 mm/1200 mm3) | from 4,000 mm (NL) | |

| Feed/folding wedge length in mm | 400 | |

| Power supply | 3 N~400 V/50 Hz/16 A | |

| Protection class | IP 65 | |

| Motor power in kW | max. 1.5 | |

| Design feature | Plateau louvre plate in mm | 8/10 |

| Feed/folding wedge liner plate in mm | 15/17 | |

Bridging values upwards / downwards (feed 1000 mm) | Nominal length 2000, overall height 600 | 250/290 |

| Nominal length 2000, overall height 700 /7251)/8302) | 290/340 | |

| Nominal length 2250, overall height 600 | ||

| Nominal length 2500, overall height 600 | 310/270 | |

| Nominal length 2500, overall height 700 /7251)/8302) | 360/330 | |

| Nominal length 2750, overall height 600 | ||

| Nominal length 2750, overall height 700 | ||

| Nominal length 3000, overall height 600 | 360/270 | |

| Nominal length 3000, overall height 700/7251)/8302) | 430/330 | |

| Nominal length 3000, overall height 800 /9002) | ||

| Nominal length 3500, overall height 800 | 520/350 | |

| Nominal length 3500, overall height 900/12003) | ||

| Nominal length 4000, overall height 900/12003) | 570/350 | |

| Nominal length 4500, overall height 900/12003) | 620/350 | |

| Nominal length 5000, overall height 1200 | ||

| Maximum permissible inclination according to EN 1398 | 12,5 % | |

| Control system | Novo i-Vision | |

| Novo i-Vision version | ● HAR1 | |

| Novoferm Communication Interface (NCI) | ● | |

Colours | RAL 5010 (gentian blue) | ● |

| RAL 7016 (anthracite grey) | ● | |

| RAL 9005 (black) | ● | |

| Other RAL colours | o | |

| galvanised | o | |

| ● Standard o Option 1) P1320 only 2) L730i only 3) VL6020 only 4) Feed rate 700/1.000 as for L730i ISO | ||

Montage

Installation methods and replacement solutions

Below you will find installation methods and replacement solutions for our dock levellers.

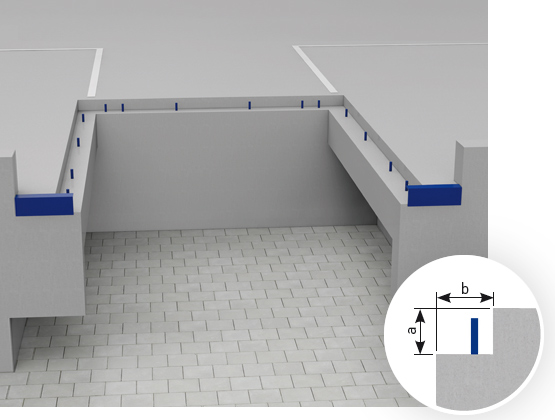

Installation methods dock levellers

Installation methods dock levellers

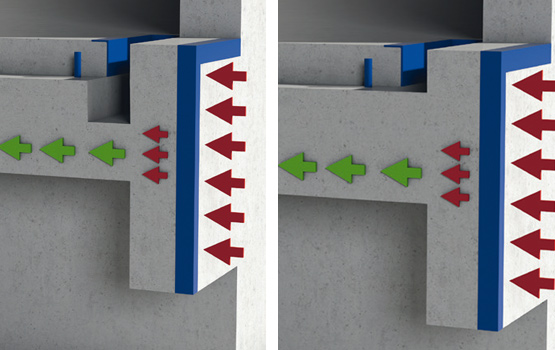

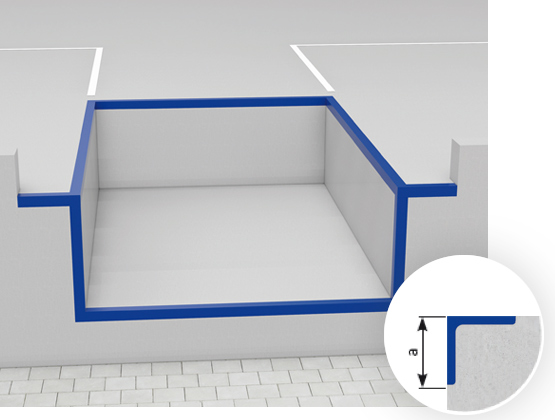

AX/AZ - EXCHANGE SOLUTION FOR WELDING

With this method, the bridge is supplied with a flat steel frame. This is then welded to the existing steel profile in the hall floor.

This variant is ideal for replacement bridges if the frame of the old bridge can remain in the floor.

The replacement can then usually be carried out within one day.

BX/BZ - PRELIMINARY FRAME FOR WELDING

The bridge is constructed with an angle frame, the legs of which are then placed in the so-called preliminary frame and welded there. This preliminary frame consists of a bracket with an attached flat bar, which is installed in the floor slab before grouting. The preliminary frame can also be supplied by Novoferm for installation on site. This variant is preferred in order to be able to complete the hall floor independently of the bridge.

The bridge can then be delivered and installed at a later date.

CX/CZ - BRIDGE FRAME FOR SETTING IN CONCRETE

Wall anchors are located on the bridge frame, which are welded to the on-site reinforcing steel studs. The concrete can then be poured.

The concreting height for this variant is max. 110 mm. The advantage of this variant is that the pit is easy to construct. In addition, the hall floor can be completely finished except for the circumferential groove.

DX/DZ - BRIDGE FRAME FOR SETTING IN CONCRETE FOR HIGHER CONCRETE STRUCTURES

This version is very similar to the CX/CZ method described above and differs only in the concreting height. The raised frame is supplied with levelling screws at the sides and rear. With this variant, floor structures of 100 - 250 mm can be covered.

This method is often used for larger quantities and the use of precast concrete elements.

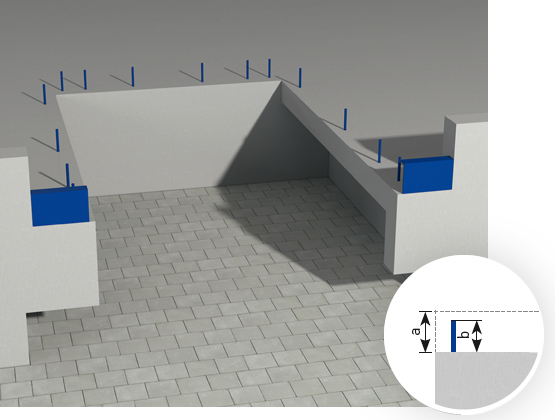

EX/EZ - BOX MODEL FOR SETTING IN CONCRETE

In this variant, the loading bridge is designed as a box that is closed on three sides. This is fixed to the floor, connected to the reinforcement and then serves as formwork. With this very simple method, the bridge is delivered and installed in the early construction phase. The time-consuming construction of a pit can therefore be omitted.

Due to its simplicity, this method is frequently used today for retrofitting bridges in existing buildings and finished floors.

FX/FZ - BRIDGE FRAME AS FLOOR MODEL

In this design, the bridge is welded to the steel profiles in the pit floor at the front. The bridge is supported on the pit floor or, in the case of bridges that can be driven under, on a wall base at the rear. Three-sided circumferential edge protection angles in the floor are recommended as pit surrounds.

This variant is most frequently used when it is not necessary to drive underneath.

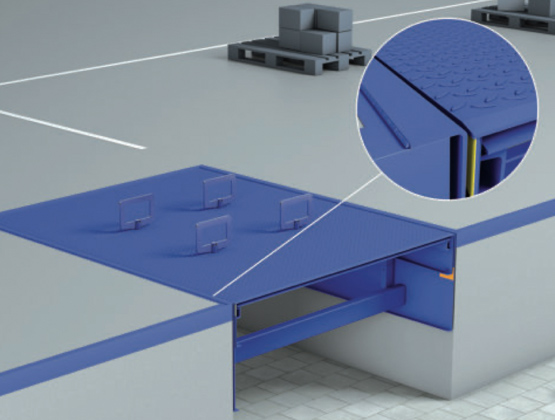

Replacement solutions Dock levellers

Replacement solutions Dock levellers

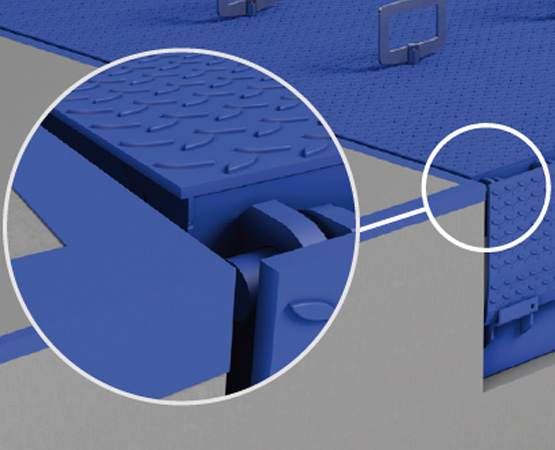

EASIEST AND FASTEST REPLACEMENT

Thanks to the new GZ frame variant, an existing dock leveller can be replaced in the shortest possible time. The side angle frames rest on the existing steel frame and can be welded after brief alignment. The rear flat steel frame provides a smooth transition from the warehouse floor to the new dock leveller.

PRODUCT ADVANTAGES

- Simple alignment

- Bridges dimensional tolerances

- No "shimming" with steel plates necessary

- No air gaps on the side frame parts