ACCESSORIES FOR LOADING SYSTEMS

Accessories for every loading situation

Different loading situations require different accessories. The right solution for the customer is crucial. Novoferm offers a wide range of different systems for this purpose.

Overview of accessories

Highlights and features

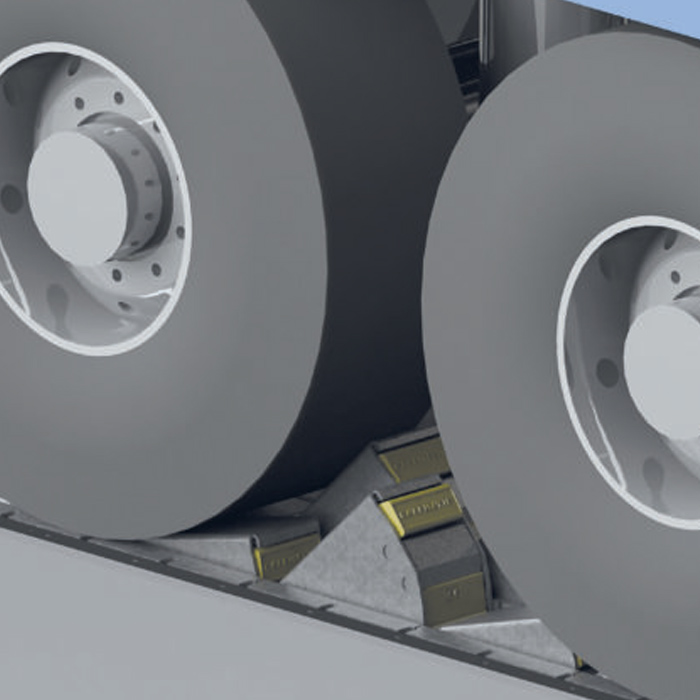

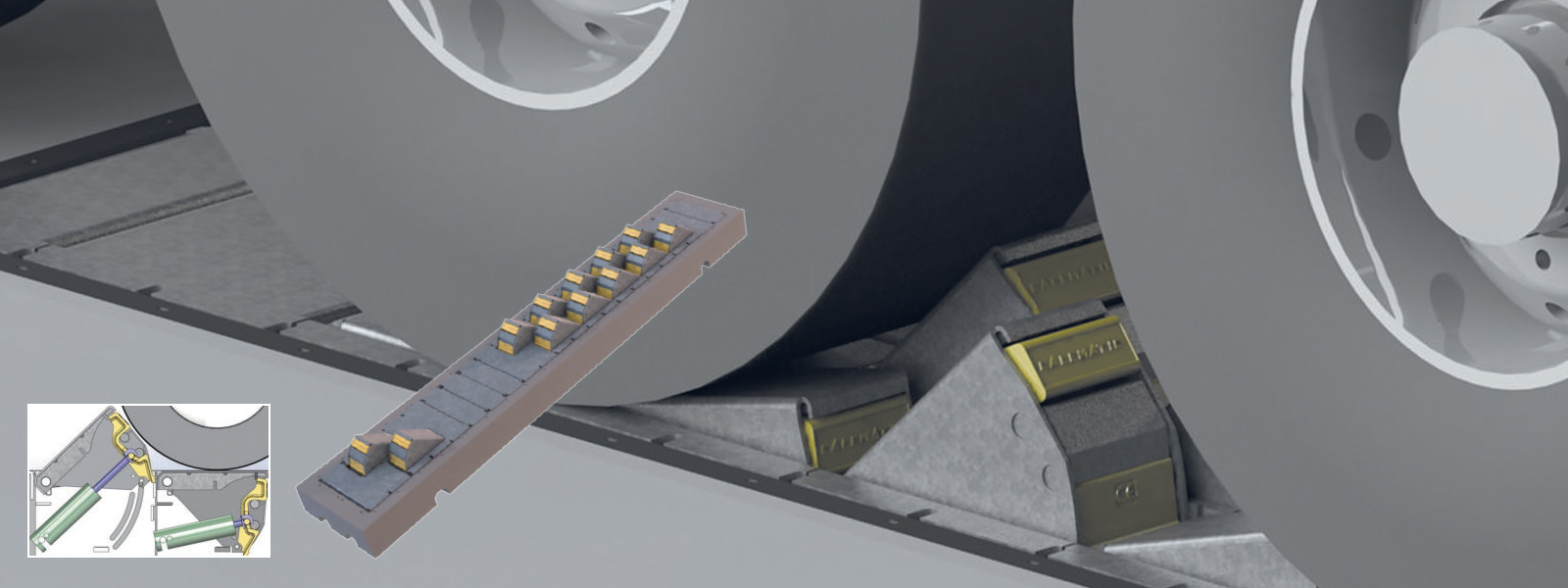

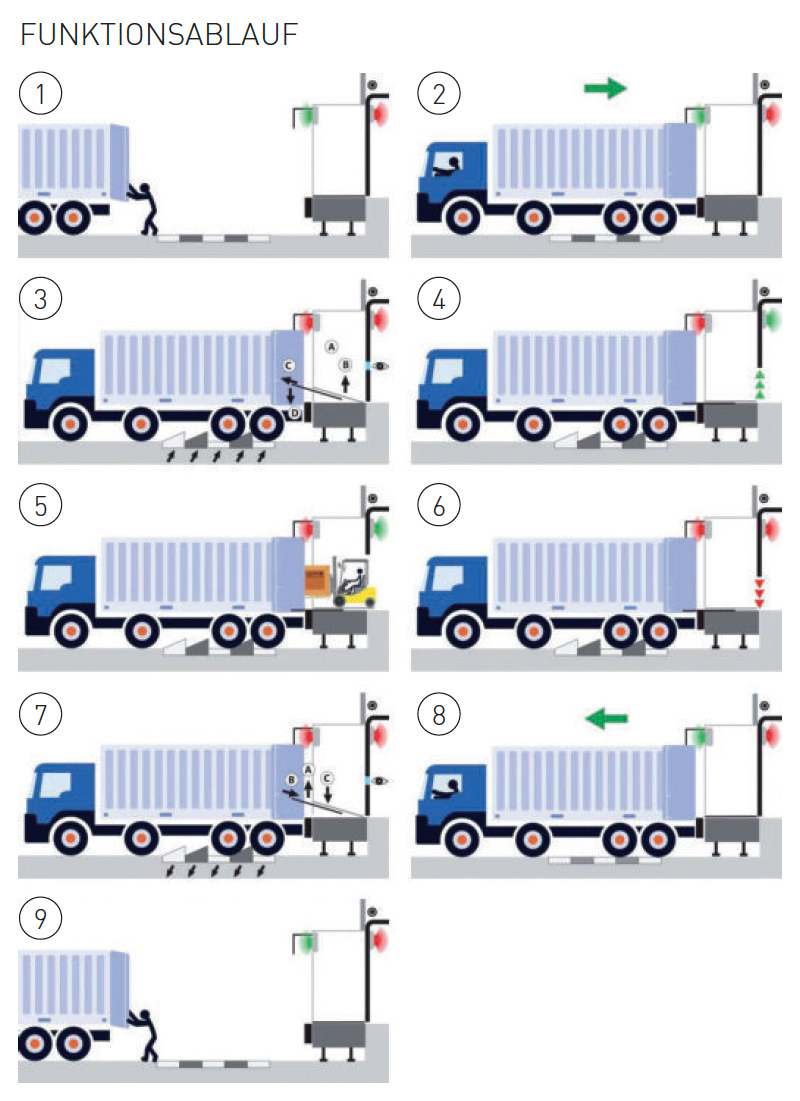

CALEMATIC SC AND DC lorry restraint systems

CALEMATIC SC UND DC

Product advantages | |

| - Extremely simple operation and handling | - Simple and safe docking of the lorry possible |

| - No disruptive superstructures that get in the way or are damaged | - Even modern lorries can be operated without any problems |

| - Extremely low maintenance costs | - Integrated component of the entire loading solution, incl. gate and loading bridge |

Lorry restraint systems sustainably reduce the risk of accidents at the loading point. The Calematic system is the optimum solution here. The new Calematic DC is a further development of the proven Calematic SC system. In addition to the familiar advantages, even greater loading safety has been achieved at lower overall costs.

The following accident hazards are prevented by using the Calematic system:

Danger due to premature departure, as there is no communication between the loader and lorry driver. Danger due to movement of the lorry caused by the truck constantly driving into the vehicle. The lorry is moved further and further forwards until the support surface of the dock leveller is no longer sufficient and it slips off the vehicle.

CONSTRUCTION

The Calematic system is designed so that it can be used anywhere: both in new construction projects and at existing loading points. The flat, recessed installation in the yard prevents damage to the vehicle when manoeuvring. The system is easy to clean, so contamination does not lead to failure. Calematic can be used in all weather conditions.

CALEMATIC SC (SINGLE CHOCK)

CALEMATIC DC (DOUBLE CHOCK)

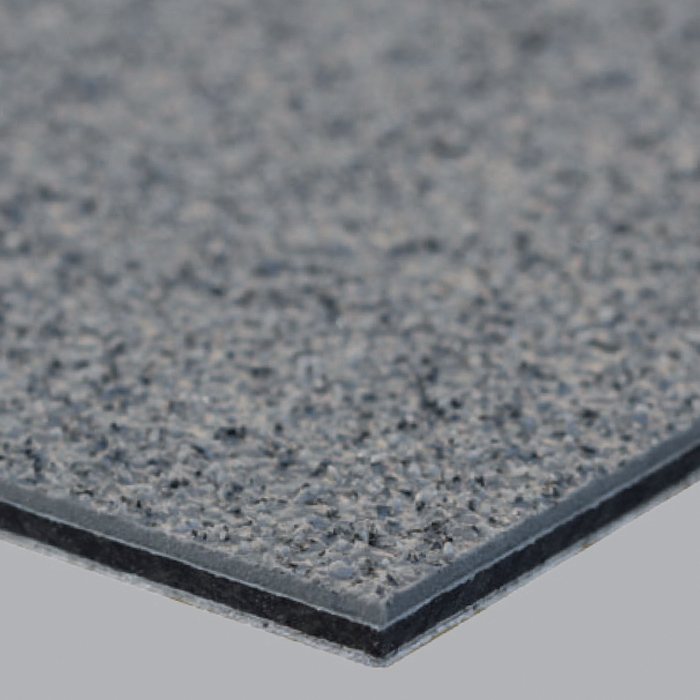

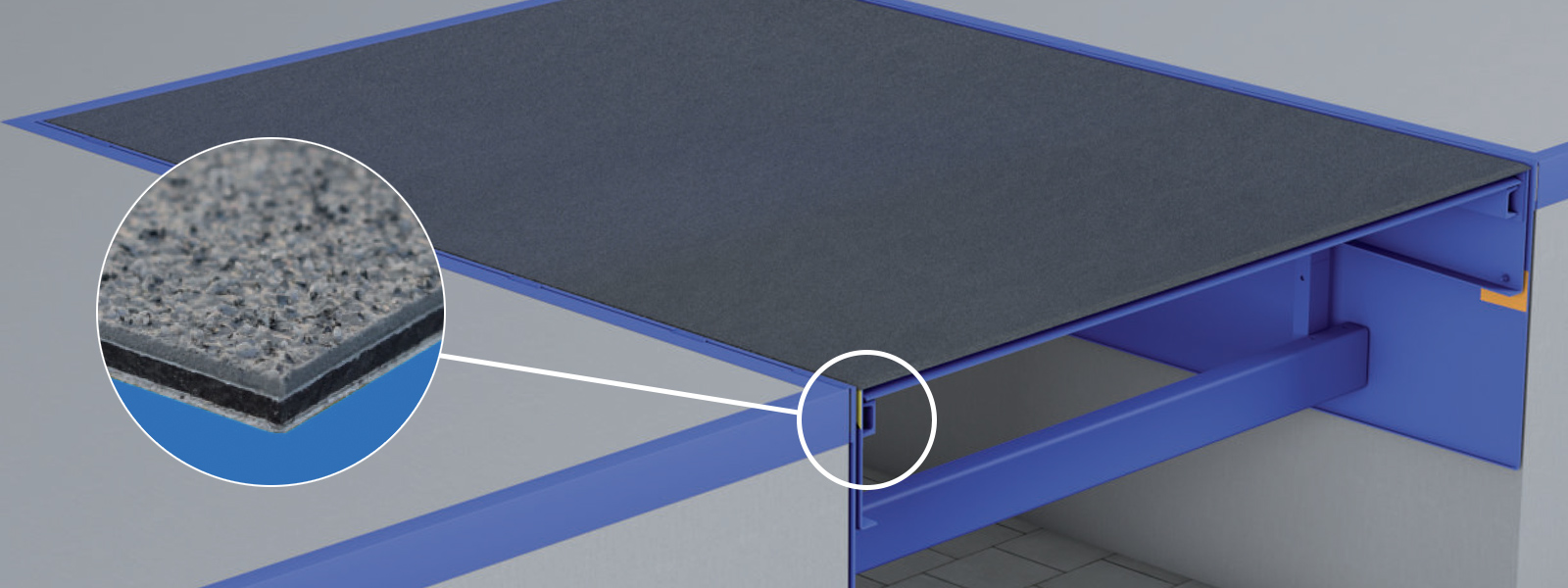

Anti-drumming solution NC SILENCE PLUS

NC SILENCE PLUS

Product benefits | |

| - Massive noise reduction of up to 85 % (25 dB) to improve occupational safety, tested by TÜV Rheinland | - High slip resistance (R12), tested by the employers' liability insurance association in accordance with DIN |

| - Amortisation in a few months and permanent cost reductions in loading possible | - Simple installation in less than 1 hour, thus causing no relevant downtime in operation |

| - Can be fixed to all loading surfaces | - Tested by DEKRA, TÜV, BG and 3G |

| - High cost-effectiveness due to - Reduction of noise below threshold values, thus possibly reducing noise protection requirements, labour surcharges, etc. - Protection of loading bridges and industrial trucks - High load-bearing capacity, temperature and chemical resistance as well as low wear and tear | |

| Feature Property | |

|---|---|

| Noise reduction | up to 25 dB (-85 % noise load) |

| Coefficient of friction | > 0.6 μD (also in wet conditions) |

| Slip resistance (R class) | R12 |

| Thickness | approx. 7 mm |

| Dimension (length x width) | 2,000 mm x 1,000 mm 2,500 mm x 1,000 mm (special customisation on request) |

| Surface weight per m² | 21 kg |

| Shore A hardness | > 83 A |

| colour | Black colour |

| Taber Abrasion Test (CS17 wheel) | 19.4 mg/1000 U |

| Taber Abrasion Test (H18 wheel) | 257.6 mg/1000 U |

| Cold elasticity (< -40 °C) | No cracks |

| Resistance to chemicals | Resistant to de-icing salts, diesel and automotive oils |

| REACH regulation | The current requirements are met. |

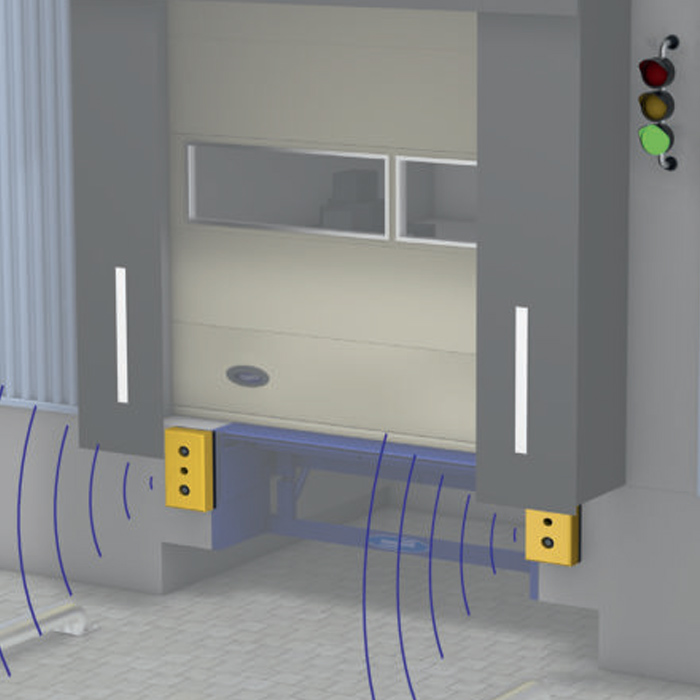

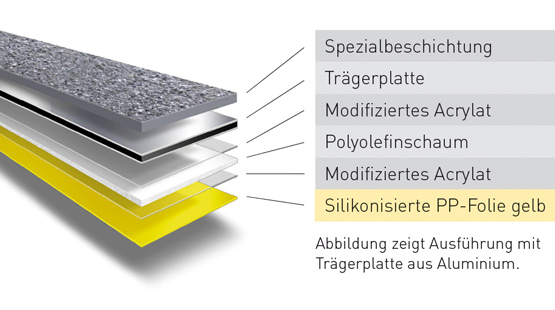

NovoEasy electronic start-up system

NovoEasy

Product advantages | |

| - Bumper made of high-performance plastic in signal yellow | - Distance measurement (lorry building) with display via external traffic light |

| - Perfect function with almost all lorry variants. Adjustments may be necessary for swap bodies | - Reset button as standard |

The ideal collision protection ensures that the lorry stops just before the bumper. This prevents damage to the building, the lorry and even the bumper. The NovoEASY supports the lorry driver in the simplest form. The sensor system, which is protected in a yellow bumper made of high-performance plastic, measures the distance between the lorry and the loading ramp and indicates this to the driver via a display element (e.g. traffic lights).

PRODUCT ADVANTAGES

- Bumper made of high-performance plastic in signal yellow

- Distance measurement (lorry building) with display via external traffic light

- Perfect function with almost all lorry variants. Adjustments may be necessary for swap bodies

- Reset button as standard

NOVOEASY MAKES LOADING EASIER IN THREE STEPS

- STEP

The lorry is still a long way from the loading point: the traffic light is green. - STEP

The lorry is approx. 100 cm from the loading point: The traffic light switches to amber. The driver increases his attention. - STEP

The lorry is 20 cm away from the loading point, just before the buffer: The traffic light turns red. The driver stops the lorry.

| Versions (mm) |

| 500 x 250 x 130 Buffer Nytrex F513 |

| 1 sensor, traffic light LED red/yellow/green |

| 2 sensors, traffic light LED red/yellow/green |

| Evaluation | ||

| Building protection | ★★★★★ | Overall rating:

25 |

| Durability | ★★★★★ | |

| Suspension travel | ★★★★★ | |

| Life Cycle Cost | ★★★★★ | |

| Visibility | ★★★★★ | |

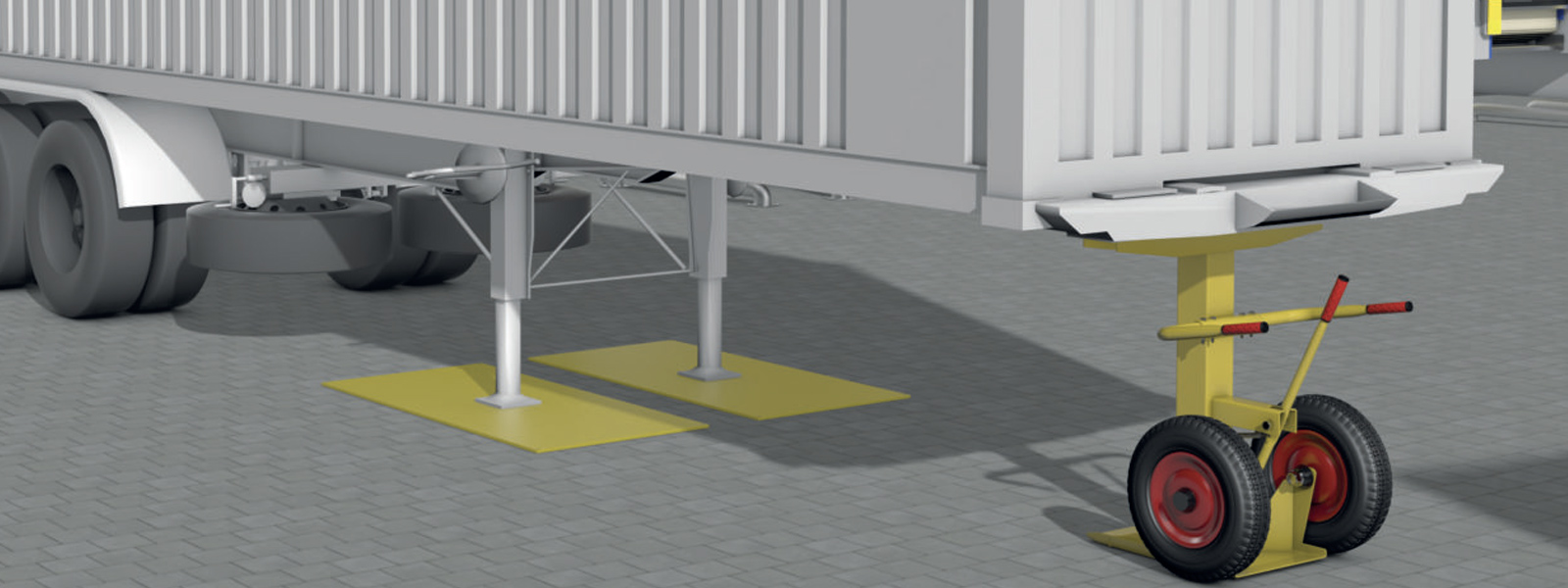

NYTREX TRAILER PLATES UND NOVO SAFETY JACK

NYTREX TRAILER PLATES UND NOVO SAFETY JACK

Product features | |

| - More safety during loading and unloading processes | - Extra wide solid steel construction with large base plate |

| - Extra large crossbar | - Height adjustable |

| - Ergonomically shaped handles for easy handling | - Adjustment via gas pressure spring |

| - TÜV-certified | |

NYTREX TRAILER PLATES –

SUSTAINABLE SURFACE PROTECTION IN THE LOADING ZONE

The Nytrex Trailer Plates prevent damage to concrete, asphalt or paved surfaces and thus avoid costly repair work in the loading bays. Available with fixings on or in the yard surface, suitable for concrete, tarmac or paved surfaces.

PRODUCT ADVANTAGES

- High-performance plastic in signal yellow

- Suitable for high loading frequency

- Optionally with anti-slip coating

| Standard sizes: |

|---|

| 2,000 x 1,000 x 16 |

| 1,000 x 1,000 x 16 |

| 1,000 x 500 x 16 |

| Other sizes (mm) available on request. |

NOVO SAFETY JACK - TELESCOPIC LOADING JACK

The Novo Safety Jack helps to increase safety when loading and unloading trailers/semi-trailers with a total weight of up to 40 tonnes. It can effectively prevent the semi-trailer from tipping over. According to BGI 582 and BGI 603, additional protection during loading and unloading work is strongly recommended by the employers' liability insurance associations.

PRODUCT ADVANTAGES

- Greater safety during loading and unloading processes

- Extra wide solid steel construction with large base plate

- Extra large crossbar

- Height adjustable

- Adjustment via gas pressure spring

- Ergonomically shaped handles for easy handling

- TÜV-certified

| Technical data | Safety Jack |

|---|---|

| Length | 550 mm |

| Width | 760 mm |

| Height | 1020-1340 mm |

| weight | 70 kg |

| Crossbar | 760 x 120 mm |

| Base plate | 470 x 425 mm |

| Air-filled wheels | ∅ 380 mm |

Further accessories

OTHER ACCESSORIES

AMPLE SYSTEMS

Traffic light systems signal to both the driver outside and the loading personnel inside whether the loading point is ready for docking or whether loading can take place. Traffic light systems with two signalling devices (red and green) are used most frequently. Red and green signals in one signalling device are also possible.

Only LED lights are used for the signal heads. LED lights are very inexpensive to maintain and have a much higher luminosity. The respective colour is still clearly visible even in sunlight. The functions of the traffic light systems are customised with the users.

BICYCLES

Wheel chocks ensure that lorries stay exactly where they are loaded. However, a standard lorry wheel chock only helps to a very limited extent.

This is why electronic wheel chocks with a connection to the gate and the loading bridge are used. The dock leveller can only be operated when the wheel chock is in contact with the wheel. A position sensor in the wheel chock ensures correct use.

It makes sense to couple the wheel chock with a traffic light system, which provides both the lorry driver and the loading personnel with information about the current status.

LOADING LIGHTS

When loading and unloading a docked lorry, there is inevitably a dark zone in the loading area, which makes it difficult to handle goods quickly and safely at the lorry-ramp interface. The Novoferm loading light is the ideal solution: it is easy to install directly on the loading hatch inside the hall without great effort and illuminates every corner of the lorry and the loading zone as bright as day thanks to the movable articulated arms.

- Version with 30 watt LED spotlights

ENTRY ASSISTANCE

Another aid that prevents damage during docking is the loading aid. In most cases, these consist of galvanised steel tubes and are mounted on the floor to the right and left in front of the loading ramp. The lorry is thus pushed into the correct position. If the lorry drives over the entry aid, this is clear evidence to the driver that it is not positioned correctly.

This prevents frequent damage to the door seals. Unloading is simplified by a correctly positioned lorry.