LOGISTICS AND PRODUCTION BUILDING

PIONEERS IN THE HISTORY OF CONSTRUCTION, SYMBOLS OF THE WORLD OF WORK

Industrial architecture is the architecture of buildings in which industrial production, manufacturing and delivery processes take place. Well-known examples include factories, workshops, warehouses and logistics facilities. Since industrialisation in the 18th century, they have been an important part of the built environment and are subject to changes in architectural styles.

But here, too, we are currently being confronted with the changes that can be summarised under the headings of Industry 4.0 and digitalisation. The industrial landscape is becoming more diverse and decentralised. Large and small production facilities are being networked with each other and adapting their structures accordingly. Many "factories" today resemble a futuristic representative building rather than the smoky brick buildings of the past. Industrial architecture thus also symbolises the state of development and paves the way for new working environments.

Requirements and solutions

Insulation and energy efficiency

REQUIREMENTS

Increasing demands on building insulation, conservation of resources and the reduction of energy consumption are predominant topics and tasks in industrial and logistics construction. As these are often large and complex structures, numerous measures are necessary to fulfil these goals and requirements.

Insulated and insulating components and devices form the basis for keeping production halls or warehouses at a uniform temperature level. It is often also a question of effectively separating different temperature zones without unnecessarily complicating operating processes.

Doors, gates and dock levellers should therefore be designed and used in such a way that unnecessary energy losses are avoided.

SELECTED NOVOFERM SOLUTIONS

| Thermo insulating industrial sectional doors in versions with 40, 60 or 80 mm panel thickness, with insulation values/ U-values of 0.35 W/m2Kto 0.5 W/m2K |

| High-speed roller shutters in various designs with an opening speed of up to 2 m/s help to maintain the desired indoor climate and reduce energy losses |

| Hydraulic dock levellers with i-Vision control with energy-saving mode as standard |

| NovoDock L730i hydraulic dock levellers as ISO dock levellers with high energy efficiency for temperature-controlled warehouses and logistics halls; fully insulated, encapsulated design - also fully insulated during loading |

| i-Vision control units with energy-saving function and energy-saving mode |

| Lion Monitoring Software 4.0 for monitoring and optimising the loading situation, enabling targeted energy cost savings |

EXAMPLES IN THE INSTALLED STATE

Security

REQUIREMENTS

Door and gate systems in the industrial and logistics sector are much more complex components than those familiar from the home, school or office sector. In addition to the usual building and installation regulations, numerous traffic and labour law aspects must also be taken into account for these products and devices.

For example, in the case of loading systemsloading systems, for example, it is important to avoid personal injury and damage to property during loading and unloading as well as to prevent damage to the vehicles themselves. There are also dangers if a lorry leaves too early due to a lack of communication between the parties involved or if a vehicle unintentionally changes position due to a forklift truck constantly driving into it. Suitable safety measures must be taken for this.

For industrial doorsthe safety of the function in the event of door malfunctions, spring breakage or the threat of a door falling must be guaranteed, as must the protection of persons from injury when opening or closing. In addition, burglar-resistant measures are required for external doors or devices that prevent doors from being operated when the wicket door is open. Provision must also be made for the situation of a power failure.

SELECTED NOVOFERM SOLUTIONS

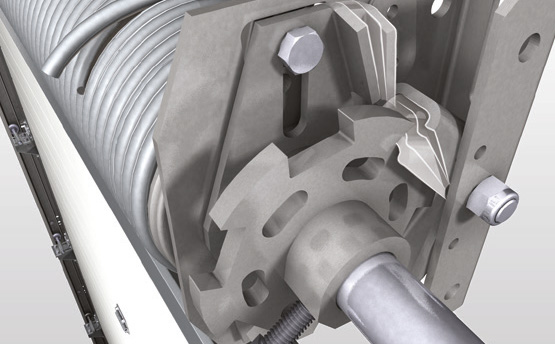

| Industrial sectional doors with integrated spring breakage protection, a rope breakage protection and a lifting or break-open protection |

| Wicket doors with integrated wicket door contact switch; this ensures that the sectional door cannot be operated when the wicket door is open |

| Fire-resistant sliding doors in T30 and T90 versions with safety brake strip (closing forces are reduced to below the requirements of DIN EN 12453) |

| Hydraulic dock levellers; equipped with special safety devices (hydraulic emergency stop, stopping of all movements in the event of a power failure, twisting of the platform prevents steps or tripping hazards, yellow and black safety markings on the sides, maintenance support, ...) |

| Infinitely adjustable levellers for safe, vibration-free loading |

| Electronic collision systems with sensor and traffic light, a collision buffer made of high-performance plastic and, in addition, electronic wheel chocks to further increase safety |

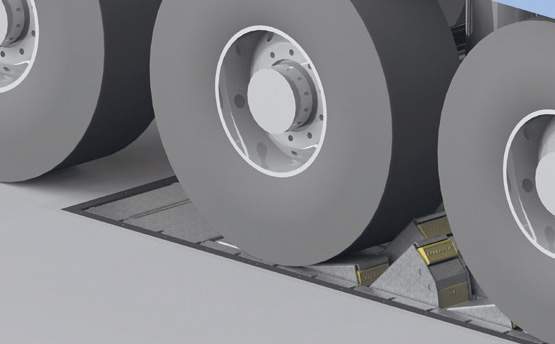

| NovoEASY electronic collision system with wheel chock; dock leveller can only be operated when the wheel chock is in contact with the wheel and the truck is reliably secured against unintentional rolling away |

| Calematic DC lorry restraint system to prevent the lorry from rolling away or driving away prematurely during loading |

| Hydraulic leveller with SLOD function as a special control system to reduce the risk of accidents when loading/unloading the truck; this ensures that the gap between the leveller and the docked vehicle is always closed by forced use of this function |

| Telescopic loading supports support the loading and unloading of trailers/semi-trailers with a total weight of up to 40 tonnes |

EXAMPLES IN THE INSTALLED STATE

Networking

REQUIREMENTS

The changes brought about by the digitalisation of industry, which are discussed under the heading of Industry 4.0, also affect processes in logistics. Logistics 4.0 solutions create full transparency regarding operating times, cycles and other data from dock levellers and doors. This allows energy costs to be reduced, unnecessary opening times to be avoided and preventative maintenance work to be carried out.

Integrating the functions of gates and dock levellers into networked systems is the next step in a scenario in which people, machines, systems, logistics and products communicate and cooperate with each other.

SELECTED NOVOFERM SOLUTIONS

Lion Monitoring Software 4.0 for monitoring, displaying and optimising the loading situation - Overview of your various locations and all associated loading points - Transparency of operating times, cycles and current status of all gates and bridges - Early error messages and detection of necessary maintenance on loading bay gates or bridges |

| Intelligent assistants allow access to the data of the connected warehouses at any time and from anywhere (via the Internet) |

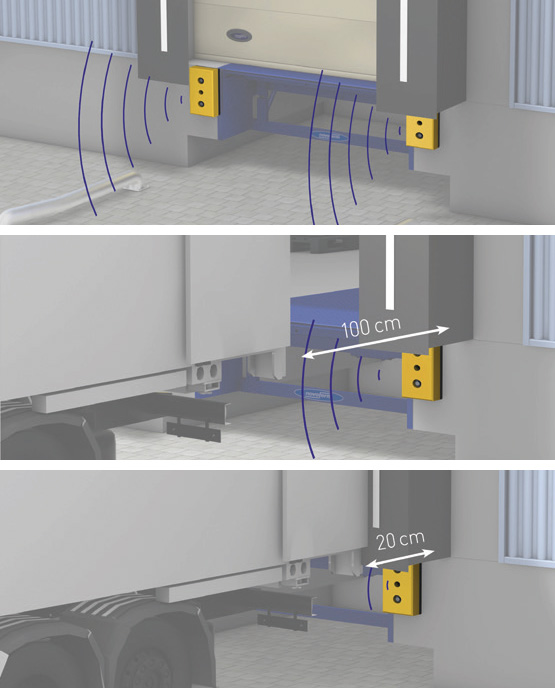

| Electronic approach system NovoEASY for communication with the truck driver via the colour of a traffic light system, taking into account a special sensor system that is located in the approach buffer and continuously measures the distance to the truck |

EXAMPLES IN THE INSTALLED STATE

Multifunctionality and design

REQUIREMENTS

Equipping industrial and logistics buildings with doors and gates is a constant challenge for planners. Numerous regulations govern the possible uses and also lead to restrictions in terms of design variety. System solutions with a multifunctional and multi-optional design can help to overcome this. Whereas in the past everything was more or less supplied in grey, today extended colour selection options should be standard. Platform strategies, as we know them from other industries, also form a basis for the integration of diverse functions into a standardised design.

Configurable basic types not only reduce the manufacturer's development costs, but also cater better to the increasingly differentiated design ideas of building owners and users. Fire and smoke protection, sound insulation and burglar resistance can all be included in modern system solutions without this being visually noticeable.

Today, industrial architecture is characterised not only by functional, but increasingly also by design ideas. Transparent construction with generous glass surfaces in the interior or translucent smoke protection closures are indicative of future developments.

SELECTED NOVOFERM SOLUTIONS

| Sliding fire-resistant doors in fire protection classes T30 and T90 as well as smoke protection versions available in many colours |

| Versatile and highly configurable property doors in thick rebate or flush-mounted design; available in fire protection classes T30 (EI2 30), T60 (EI2 60) and T90 (EI2 90) as well as smoke protection, multi-purpose, sound insulation and security doors; available in numerous design variants, decors and colours |

| Tubular frame doors made of glass or metal in T30 (EI2 30) and T90 (EI2 90) versions for a transparent room experience |

| T30 (EI2 30), T60 (EI2 60) and T90 (EI2 90) fire-resistant security doors available with tested security to RC 2 (WK2) or RC 3 (WK3) in accordance with DIN EN 1627 |

| Steel security doors available with tested security to RC 2 (WK2), RC 3 (WK3) or RC 4 (WK4) in accordance with DIN EN 1627 |

EXAMPLES IN THE INSTALLED STATE

Escape route systems

REQUIREMENTS

Structural fire protection and the design of escape and rescue routes are also key requirements in industrial buildings and workplaces in general. Evacuation in an emergency, for example in the event of a fire, is ensured here by emergency exit locks in accordance with DIN EN 179 and panic door locks in accordance with the EN 1125 standard.

When dimensioning door, corridor and staircase widths, all rooms and traffic routes that lead to the escape route and are specially labelled must be taken into account. Their width should be coordinated so that employees, visitors and suppliers can leave a building safely and quickly.

SELECTED NOVOFERM SOLUTIONS

| Multifunctional doors with anti-panic lock variants in accordance with DIN EN 179 and DIN EN 1125 with numerous fitting options |

| Emergency exit systems (lever handle and panic lock) in accordance with DIN EN 179 or anti-panic locks (anti-panic bars and locks) in accordance with DIN EN 1125 can be integrated into doors |

| Self-locking panic locks |

| Anti-panic locks with single or multi-point locking - with various passage functions |

| Push or touch bars to DIN EN 1125 for quick and safe exit from the building |

| Escape door locking with additional escape door strike above the main lock |

EXAMPLES IN THE INSTALLED STATE

Selected equipment and accessories

SAFETY | COMFORT | |

| Slack rope safety device for industrial sectional doors; the electric operator is immediately de-energised if one of the suspension ropes breaks or slackens | i-Vision control units with user-guided control of doors and dock levellers and with maintenance interval display | |

| Safety light barriers in versions with reflector and with transmitter and receiver; no closing of the door if the light beam is interrupted | Large selection of operating elements, from hand-held transmitters (2- and 4-channel) to buttons (pull, push and key buttons) | |

| Safety light grid with larger detection area compared to the safety light barrier | Pull switch for operating an industrial sectional door by a forklift driver without the driver having to dismount | |

| Traffic light systems signal both the driver in the outdoor area and the loading personnel in the indoor area whether the loading point is ready for docking or whether loading can take place | Additional operating units for controlling gates from a gatekeeper system | |

| Loading lights with movable articulated arms for daylight illumination of every corner of the loading zone | Traffic lights and flashing beacons on both sides of industrial doors to regulate through traffic | |

| Entry aids in the form of galvanised steel tubes, which push the truck into the correct position | ||

| Various motion detectors (radar and infrared) and induction loop detectors for detecting objects |

Generate product solutions for your construction project

The Novoferm solution generator guides you to the solution you want for your building project in just a few steps.

- Quick generation of product recommendations for your building project based on your pre-selection

- Determination of gross prices for your configuration

- Simple creation of product data sheets

- Generation of tender texts & BIM models ...