References on production and logistics

Let us inspire you

In the following references, we present examples of logistics and production buildings in which high-quality Novoferm products have been installed. Sometimes unusual, sometimes impressive, the range of possible applications is very broad.

Requirements and solutions

Handling hall BTG - Fledberg & SOHN GMBH & CO. kg Bocholt

FLEXIBLE DISTRIBUTION NODE

Medium-sized, with short decision-making paths, but at the same time internationally networked - or in short: maximum flexibility characterises the forwarding company BTG-Feldberg & Sohn. The same applies to the new 6,000 m² distribution centre in Bocholt.

Here, where consumer, industrial and hazardous goods roll over 74 loading bridges from morning to night, special requirements apply to the loading technology. With the support of Novoferm, BTG has therefore untied or tied many a "knot" as required ...

| Client | Client BTG Feldberg & Sohn GmbH & Co KG, Bocholt |

| General contractor | Depenbrock Bau GmbH & Co. KG, Stemwede |

| Usable floor space approx. | 6.000m2 |

| Total costs approx. | 7.5 million euros |

| Built-in finishes | |

| Hydraulic dock levellers "NovoDock L 500i" with i-Vision TA control system, loading lights, traffic light system and steel buffers | 74 |

| "NovoSeal S 420" dock shelters with spring-back aluminium frame construction | 74 |

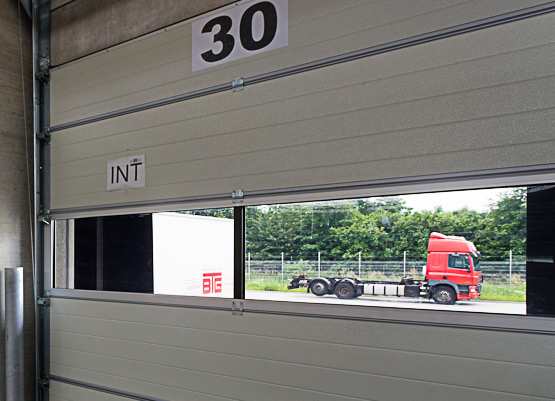

| Thermal sectional doors with 45 mm thick PUR hard foam core and "NovoLux" window panels | 77 |

SAFE TRACK TO SUCCESS

Freight forwarders' transshipment halls are a special kind of hub. Almost all goods are moved here. Therefore, a key requirement is that even highly sensitive goods must be loaded without damage.

The hydraulic dock levellers "NovoDock L 500i" solve the problem. They can be positioned steplessly, and when the feed is fully extended, the plateau and feed lip form a flush surface without thresholds or tripping hazards. This not only protects the freight when travelling over the bridges, but also the conveyor vehicles.

KNOTS SOLVED: DOCK LEVELLERS WITHOUT THRESHOLDS

Freight forwarders' transshipment halls are a special kind of hub. Almost all goods are moved here. Therefore, a key requirement is that even highly sensitive goods must be loaded without damage.

The hydraulic dock levellers "NovoDock L 500i" solve the problem.

They can be positioned steplessly, and when the feed is fully extended, the plateau and feed lip form a flush surface without thresholds or tripping hazards. This not only protects the freight when travelling over the bridges, but also the conveyor vehicles.

KNOTS LINKED: FLEXIBLE GATE SEALS

7.5 tonne trucks, swap bodies, trailers, articulated lorries - almost anything with wheels can dock in a freight forwarding hall.

The challenge:

Regardless of the dimensions of different vehicle superstructures, employees and goods must be protected from draughts and driving rain during loading. The "NovoSeal S 420" door seal combines all of these requirements.

Novoferm manufactures the seals from robust but flexible tarpaulin material. Precisely defined slits in the tarpaulins and an aluminium frame stem with springback ensure optimum adaptation to different vehicle types.

BREAKING THROUGH KNOTS: SAFE LOADING PROCESS

Freight forwarders earn their money with loading and transport. The prerequisite for this: it has to be fast - but not at the expense of safety.

This "Gordian knot" of conflicting requirements is "cut" by a few technical details on the loading units: Large windows in the gates allow dangerous traffic in front of the ramp to be seen at a glance. Loading lamps illuminate light-tight superstructures well and prevent collisions. Only when the dock leveller has been retracted and is therefore clear, does an external traffic light signal that the truck may depart.

KNOTS DOUBLED: BUILDING AND VEHICLE PROTECTION

A painful experience in everyday haulage:

When trucks weighing tonnes roll onto the loading ramp, the enormous force regularly leads to expensive repairs to buildings and vehicles. If the train is not lowered to normal level, the door is often even destroyed.

Novoferm protection:

Instead of conventional rubber buffers, wear-free steel buffers are used. Like a double knot, the outer steel plate and the inner rubber core with a spring deflection of around 80 mm form a solid unit and safely absorb even massive impacts. In addition, buffers in two different heights protect the doors from lorries with excessively high loading edges.

WELL NETWORKED

In order to be able to offer almost all transport and logistics services, BTG-Feldberg & Sohn is closely linked to the system transport companies GEL, Cargo-Line and ELVIS. The Bocholt-based freight forwarder's fleet comprises around 50 lorries and drives to countless ramps every day. This experience is one of the reasons why BTG-Feldberg & Sohn decided to use only loading technology from Novoferm in its own logistics centre.

Freudenberg Filtration FFT logistics centre

SAFE AND EFFICIENT

NovoEASY was deliberately chosen for the construction of the Freudenberg Group's new logistics centre in Kaiserslautern.

The ultra-modern sensor-controlled approach system for safe and efficient loading prevents considerable damage caused by lorries docking. State-of-the-art loading systems from Novoferm are used in the logistics halls. The client was particularly impressed by the combination of proven technology and new ideas.

| Project | Freudenberg logistics centre Filtration FFT |

| Project location | Kaiserslautern |

| Architect | Architectural office Edinger GmbH |

| Completion date | 2013 |

| Requirement profile | High demands on modern, efficient and safe loading technology |

| Novoferm products | NovoEASY, NovoDock, NovoSeal and accessories |

ON TOP: HIGHTECH ZUM ANDOCKEN

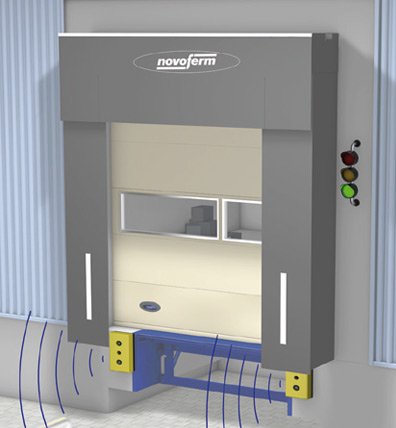

With its predictive technology, this intelligent collision protection system helps to stop lorries safely before they reach the collision buffer, thus preventing damage to the building or vehicle. The key features of this innovation are An electronic collision system with sensor and traffic light, a collision buffer made of a new type of high-performance plastic and, in addition, an electronic wheel chock to further increase safety.

With the NovoEASY collision system, communication with the lorry driver - internationally easy to understand - takes place via the colour scheme of a traffic light system. A green LED light indicates which station is ready for loading. If the traffic light changes to amber when the lorry pulls away, its loading edge is only about 80 cm away from the ramp. If the light changes to red, the vehicle has reached the ideal position and the driver stops. This is made possible by a special sensor system that is located in the approach buffer and continuously measures the distance to the lorry.

Release issued

The wheel chock is an important safety component of the new approach system. The dock leveller can only be operated when the wheel chock is in contact with the wheel and the truck is reliably secured against unintentional rolling away.

These simple and clearly structured processes make docking the lorries much easier, prevent damage and increase overall work safety. As a result, the particular advantages of NovoEASY are not only evident in Kaiserslautern in the tough day-to-day loading traffic, but also in operational financial controlling. The new electronic approach system in combination with the high-performance buffers sustainably increases the economic utilisation rate of logistics facilities.

With its perfectly harmonised loading systems, Novoferm was also able to offer a customised solution here.

STATE-OF-THE-ART LOADING TECHNOLOGY - SAFE DOCKING AT THE HALL GATE

SOLUTIONS

Where many heavy goods vehicles weighing several tonnes manoeuvre every day and cargo rolls over bridges, special requirements apply to the loading technology.

The basis for this is a tried-and-tested and technically reliable system loading technology.

The large loading doors are made of thermo sections, manufactured with a strong PUR rigid foam core.

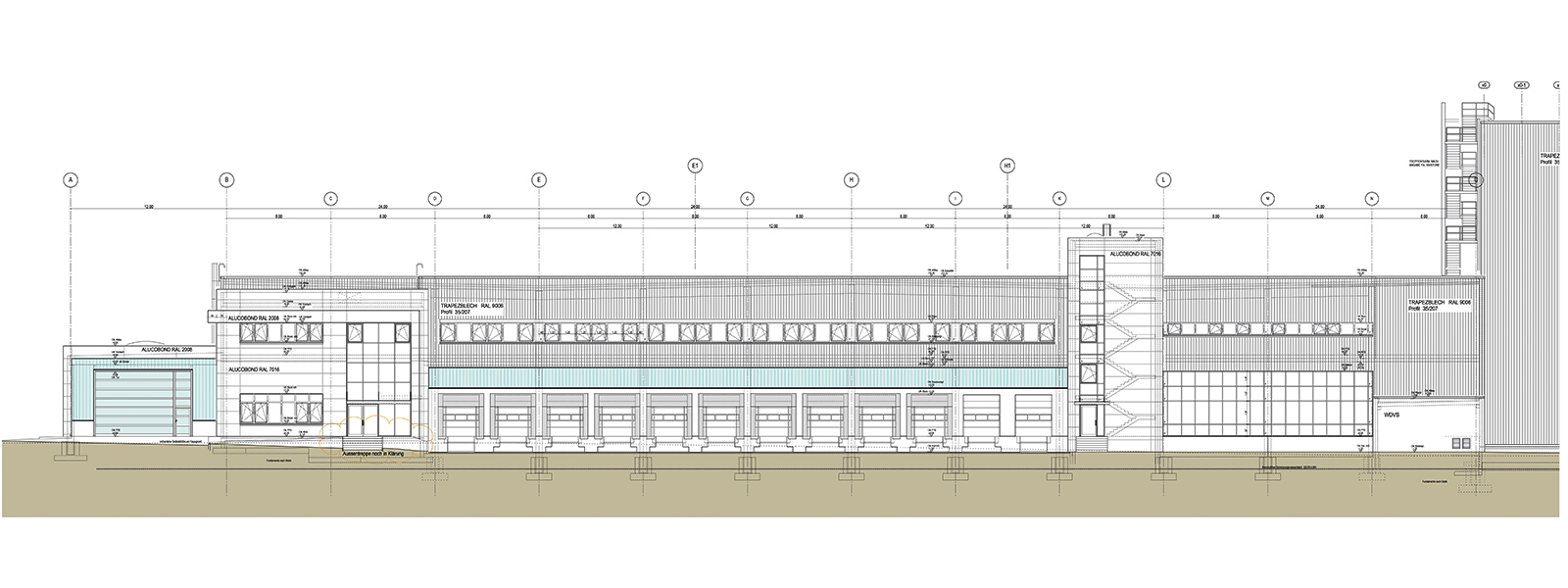

The new multifunctional hall measuring around 12,000 square metres takes centre stage.

Six state-of-the-art docking stations allow lorries to be loaded and unloaded safely and efficiently.

OUR PRODUCTS

Logistics centre symbiolog

DOOR AND GATE FOR LOGISTICS - WARM, SAFE AND WITHOUT COLD FEET

In Burgbernheim in Franconia, symbiolog built a weather-independent dispatch centre with a floor area of over 11,000 m², especially for long goods. A high-bay warehouse is connected to the underfloor-heated dispatch centre, while insulated loading stations and structural fire protection from Novoferm round off the concept. The company symbiolog is a spin-off of Müpro GmbH, a producer of fastening and fire protection technology. The beginnings of the project date back to 2014, when Müpro GmbH planned to build a distribution centre on this site.

However, things turned out differently:

The logistics division was spun off and the current company became an independent logistics service provider. It no longer only packs and despatches typical Müpro products such as pipe clamps, sealing tapes and fire protection products, but also long goods measuring up to 6,000 mm.

| Project | Logistics centre symbiolog |

| Project location | Burgbernheim |

| Client | Symbio-Immobilien AG Winterhur, Switzerland |

| General planning & project management | Baumann Gesamtplanungs GmbH Stuttgart, Germany |

| General contractor construction | Wolff & Müller Waldenburg |

| Completion date | February 2017 |

| Requirements profile | High demands on modern, efficient and safe loading technology and on high-quality, functional fire protection solutions |

| Novoferm products | NovoDock L530i and VL6020 dock levellers with Thermo 40 mm sectional doors, S420 door seals, rubber buffers and drive-in aids Industrial sectional door aluminium 40 mm (6,000 x 5,000 mm) with side door of the same size NovoFire® system aluminium tubular frame doors: T30-1, F90 Glazing with T90-1,T0-1 System NovoPorta Premio sheet steel doors: T30-1 / T30-2, T90-1 / T90-2, MZ-1 / MZ-2 Block frame type 1 with louvre |

Cold store loading

The latter cannot be placed in the transport vehicle from the rear using a conventional loading station; the goods must be lifted onto tarpaulin trailers from the side using a forklift. It should also be possible to load the goods regardless of the weather.

There are two access roads opposite each other, which are designed for articulated lorries in terms of their clear heights and widths. These are closed with industrial sectional doors from Novoferm, a leading European system supplier of doors, gates, frames and operators as well as loading systems. The doors are from its 40 mm profile series. The door sections are semi-transparent and have side doors that enable fast and safe pedestrian passage. A firewall thermally separates the unheated cold hall from the warm storage and logistics area.

Fire compartments

In addition to making the building weatherproof, it was also important to reliably separate the interior areas, particularly in terms of fire protection. The packaging warehouse is protected by an extra-wide, double-leaf Novoferm steel door from the NovaPorta Premio series with fire resistance class T90. On the ground floor, three Premio sheet steel doors of the same design and also designed in a T90 version connect the dispatch hall with the adjoining administration area. A grating staircase leads to the upper floor. Here, a Novoferm T90 aluminium tubular frame door from the NovoFire® range provides direct and transparent access to the adjoining offices.

Additional NovoFire® tubular frame doors also provide optimum fire protection for the stairwell, which is classified as an escape route. This begins directly at the main entrance. To the left is the reception area. NovoFire® F90 glazing with an integrated T90 fire resistance class tubular frame door separates the two areas.

SOLUTIONS

Cold stays outside everywhere

The hall complex is not heated by radiators or even radiant heaters, but by underfloor heating operated in the low-temperature range. Until now, such a solution was unusual in the logistics sector, as both the heating pipes and the screed were quickly damaged by the weight of forklift trucks travelling around. The general planner Ulrich Baumann circumvented the problem by insulating the entire floor slab from below and concreting the heating loops directly into the floor slab.

To ensure thermal separation and fire protection requirements, thermally insulated loading stations and fire doors from Novoferm were installed. The NovoDock L530i is designed to reduce potential thermal bridges during lorry loading.

In addition to insulating door seals, these are also equipped with collision buffers and mechanical parking aids for safe reversing to the correct loading position.

OUR PRODUCTS

Photo motifs:

© Photos Novoferm

© Grafik Baumann Gesamtplanungs GmbH