References for residential construction

Let us inspire you

In the following references, we present examples of single and multi-family homes in which high-quality Novoferm products have been installed. Some of them are unusual, some are impressive and the range of possible applications is very broad.

Requirements and solutions

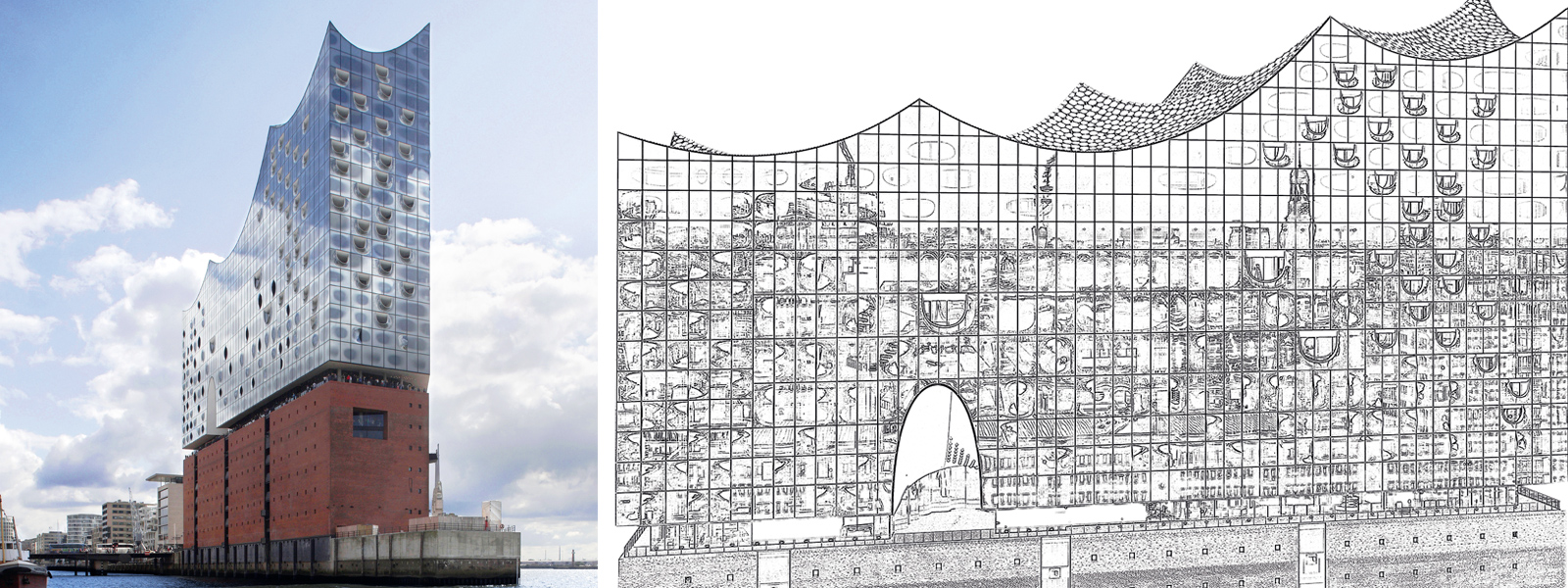

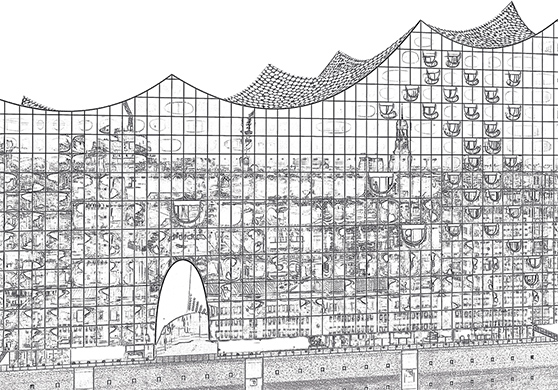

Living in the Elbphilharmonie

FIRE PROTECTION DOORS IN THE ELBPHILHARMONIE HAMBURG

Shining safety

The radiance of the Elbphilharmonie makes it easy to forget, but this building is a very extensive refurbishment. The original Kaiserspeicher now forms the 37 metre high base on which the striking glass and steel roof landscape designed by Basel architects Herzog & de Meuron sits. This has increased the available floor space to 120,000square metres, which of course covers far more than just the concert hall and its periphery. The Elbphilharmonie also includes a 5-star hotel with 244 beds and, at its western end, 45 exclusive condominiums spread over 17 floors.

While the completion of the actual concert hall was driven forward with great political will and was officially opened on 11 January 2017, the interior construction of the condominiums by HOCHTIEF Infrastructure GmbH continues to this day.

| Project | Exclusive living in the Elbphilharmonie |

| Project location | Hamburg |

| Client | Elbphilharmonie Hamburg Bau GmbH & Co. KG, represented by ReGe Hamburg Project Realisation Company |

| The architecture | Herzog & De Meuron Hamburg/ Basel |

| General contractor | Hochtief Engineering GmbH Essen |

| Requirement profile | Integration of the fire protection solutions into the overall design concept, quality and reliability of the products in combination with comfort and design, exclusive design of the door surfaces |

| Completion date | December 2018 |

| Novoferm products | System fuego light T30-1 / T30-2 steel tubular frame doors |

FINELY POLISHED SURFACES

The condominium part of the building can be reached via a car park reserved for residents. There is also an internal connection to the forecourts of the Philharmonie. All entrances lead into a classic reception area. These corridors are closed with single-leaf fire protection doors in an exclusive design by the manufacturer Novoferm: a fire protection glass of resistance class F30 is surrounded by a shiny tubular frame made of stainless steel. "The surface is called 'finely polished'," explains Jörn Lohmann, Product Manager for fire protection tubular frame doors at the Isselburg-based manufacturer.

"It's a skill that not everyone has: The surface should look like chrome afterwards. To achieve this, the surfaces have to be repeatedly sanded and polished."

All of the tubular frame doors installed in the Elbphilharmonie are flush with the ceiling and have no central crossbars. These are semi-public areas where users can be assumed to have a certain degree of local knowledge. It was also possible to dispense with horizontal panic bars and it was permissible to fit regular lever handle sets. Product manager Lohmann emphasises that, despite their exclusive design, the doors are on a par with normal tubular frame variants in terms of security: They were also supplied in smoke protection (RS) quality and also have a retractable rubber lip that lowers onto the valuable wooden floor when closed.

Flush-mounted

While the stainless steel fire doors are reserved for the foyer, black lacquered tubular frame doors can be found on the flat levels at the transition from the lift lobbies to the access corridors.

They consist of a fixed and a movable leaf and are basically normal doors, but a small planning detail makes them something special:

They are flush-mounted to the wood panelling of the wall and also fulfil fire resistance class F30. To achieve this, the door frames were first placed in front of the carcass with a substructure in accordance with the authorisation and were initially slightly raised. The wall was then virtually doubled up with the wood panelling and the dark frame was carefully attached.

THE NOVOFERM SOLUTIONS

Few doors - a lot of care!

With barely 30 doors, the project was a small order for door and gate manufacturer Novoferm. However, a great deal of experience and precision was required for both the production and the subsequent installation, which is why the globally operating company from the Lower Rhine did not miss the opportunity to send its own fitters to Hamburg.

The biggest technical challenge during production was the frame corners of the finely polished fire doors. Unlike aluminium profiles, all steel profiles in door and window construction are always mitre-welded at their corners. The resulting diagonal seams have to be sanded over several times before fine polishing to make them completely invisible. The stainless steel profiles used are similar in shape to conventional frame construction products, although the choice is somewhat more limited: they are not available in all size combinations, either in terms of their slenderness or their width.

CONSTRUCTION PROJECTS bONN OBERKASSEL

SIMPLY FOAM T30 DOORS

The backfilling of corner frames with Novoferm fire protection foam is tested as a unit for T30-1 N2/50 and T30-2 N22/50 fire doors in accordance with the criteria of DIN EN 1634-1 and approved by the building authorities in accordance with DIN 4102-5.fire doorfrom Novoferm an additional, professional installation option that offers significant time and cost benefits, especially when renovating and modernising existing buildings - as numerous practical experiences of metal fabricators and fitters have shown.

| Client | Rheinische Beamten- Baugesellschaft mbH, Cologne |

| Construction work | Bauelemente Banach GbR, Lindlar |

| Novoferm products | Fire doors T30-1 N2/50 with fire protection foam 26 |

"OVER 20 PER CENT LESS ASSEMBLY TIME"

One of the first people to use Novoferm fire protection foam in practice was Gerhard Banach, managing co-owner of "Bauelemente Banach GbR" from Lindlar.

In the business for more than 35 years and with experience of 1,000 to 1,500 door installations a year, his conclusion is clear: "In direct comparison, foam installation is at least 20 per cent faster than mortar installation."

Installation manager Uwe Rein, who has been with Banach for almost 30 years, goes even further: "Foam installation eliminates a lot of additional work such as mixing the mortar, covering floors and the often time-consuming tidying up and cleaning of the construction site and work equipment.

Depending on the installation situation, fire protection foam can even save up to half the time."

Step 1: Insert frame.

The frame backfill with Novoferm fire protection foam is permitted for T30-1 N2/50 or T30-2 N22/50 fire doors up to a size of 1,350 x 2,500 mm (single leaf) or 3,000 x 3,000 mm (double leaf) with a corresponding corner frame in masonry or concrete. The corner frame is fixed as usual in accordance with the applicable installation guidelines using either screw, dowel or weld-on installation.

STEP 2: BACKFILLING WITH FIRE PROTECTION FOAM

Once the frame has been properly fixed, the space between the frame and the wall, which has been cleared of dust, is moistened with a water spray to increase the swelling effect of the fire protection foam.

The gap is then completely filled with foam in two phases using a foam gun:

first the lower sections, then the front sections. The subsequent drying time required is at least 30 minutes.

A removable self-adhesive label is affixed to the foam can to document that the installation conforms to approval requirements.

Step 3: Create wall connection

The protruding foam is simply removed with a sharp knife or cutter after curing (min. 30 minutes).

Depending on the fixing variant, the transition between the frame and wall can now be plastered or (on the opposite hinge side) neatly covered with an optionally available self-adhesive and sealable plastic profile with a soft lip.

Step 4: Fitting the door leaf and accessories

The installation and fine adjustment of the door leaf, handle set, sealing profile and other accessories such as an overhead door or panic closer are carried out in the usual way, regardless of the type of frame back panel.

FIRE PROTECTION IS IMPORTANT

The Theresienau 1-11 construction project in Bonn-Oberkassel is a typical example of modernisation work on existing buildings.

Six apartment blocks with 32 residential units are being adapted both visually and technically to meet current living standards.

This includes compliance with current fire protection regulations - and thus requires the installation of T30 doors in accordance with current building regulations.