INDUSTRIAL DOOR DRIVE SYSTEM DCC 80

DCC 80: DIRECT CURRENT COMMERCIAL 80 NM

The new DCC 80 combines the advantages of different drive and control types and impresses with its smart technology and robust design. A soft start and soft stop function, self-learning force detection, the high opening speed (up to 30 rpm) and numerous connection options for accessories of all kinds are just some of the many advantages of the DCC.

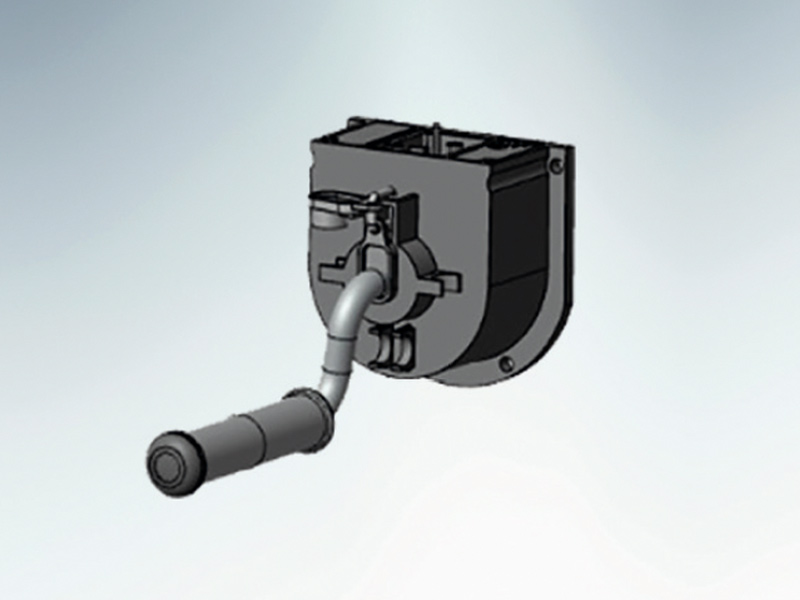

It is available in the emergency hand chain, emergency hand crank or quick release versions. The emergency hand chain and crank are also available with an additional maintenance release.

Highlights DCC 80

This video presents the highlights of the DCC 80 industrial door operator system from Novoferm.

You can find further animations under:

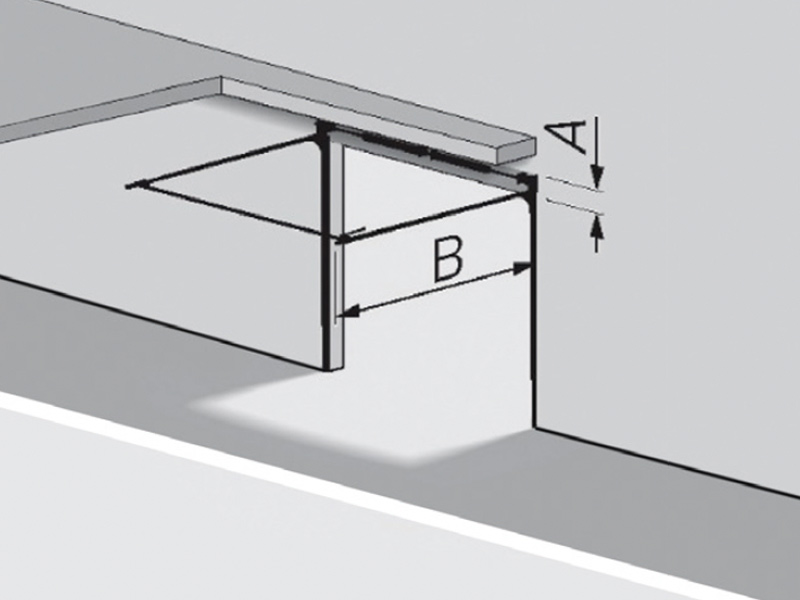

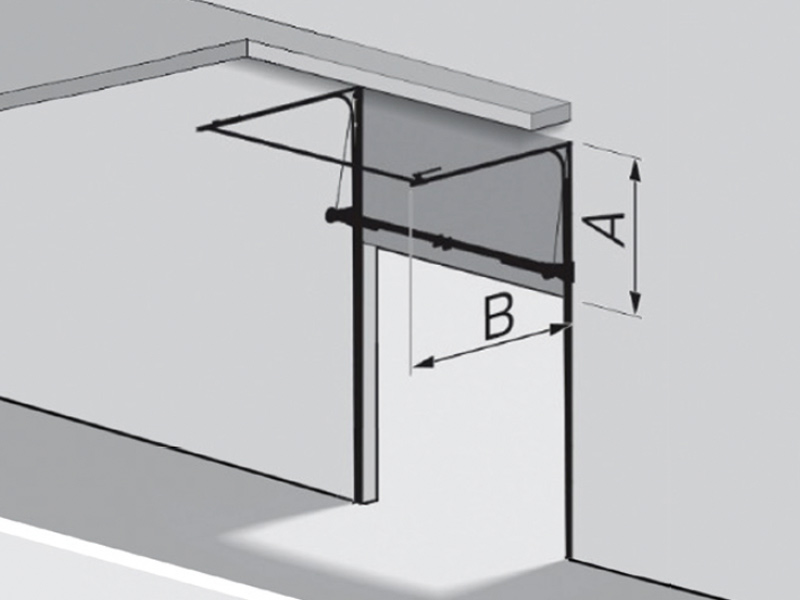

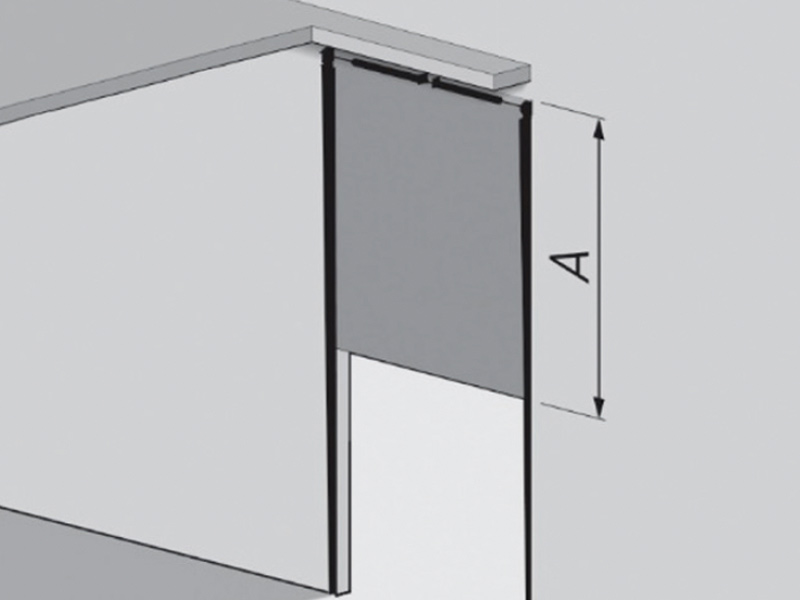

APPLICATION AREAS

(Max. 20 m² door size, max. 260 kg door leaf weight)

EXECUTIONS

Your plus points at a glance

- Emergency actuation variants (emergency hand chain, emergency hand crank, quick release, maintenance release)

- Soft start and soft stop function

- Up to 80 Nm torque and self-learning force detection

- Up to approx. 180 kg door leaf weight no closing edge safety device, slack rope switch and spiral cable required (depending on door type/size)

- 230 volt 1-phase connection and battery backup can be connected

- Prioritised opening - function like SHEV (optional)

- Additional end position and connection board (optional)

- Door status relay for operating a traffic light

- Electromechanical door lock can be connected (EDL 100) - with RJ45 plug

- Cycle counter/maintenance cycles adjustable and error history via app (last 10 errors)

- Bluetooth dongle for commissioning and service (optional) and ready for online monitoring

- 40 radio channels or buttons can be taught in

- Pull-in safety device can be connected directly to the motor head

- RSE system (Industrial Set B, radio-controlled closing edge)

- Extended setting options via app (copying and loading of control configurations)

- Stand-by mode < 1 W

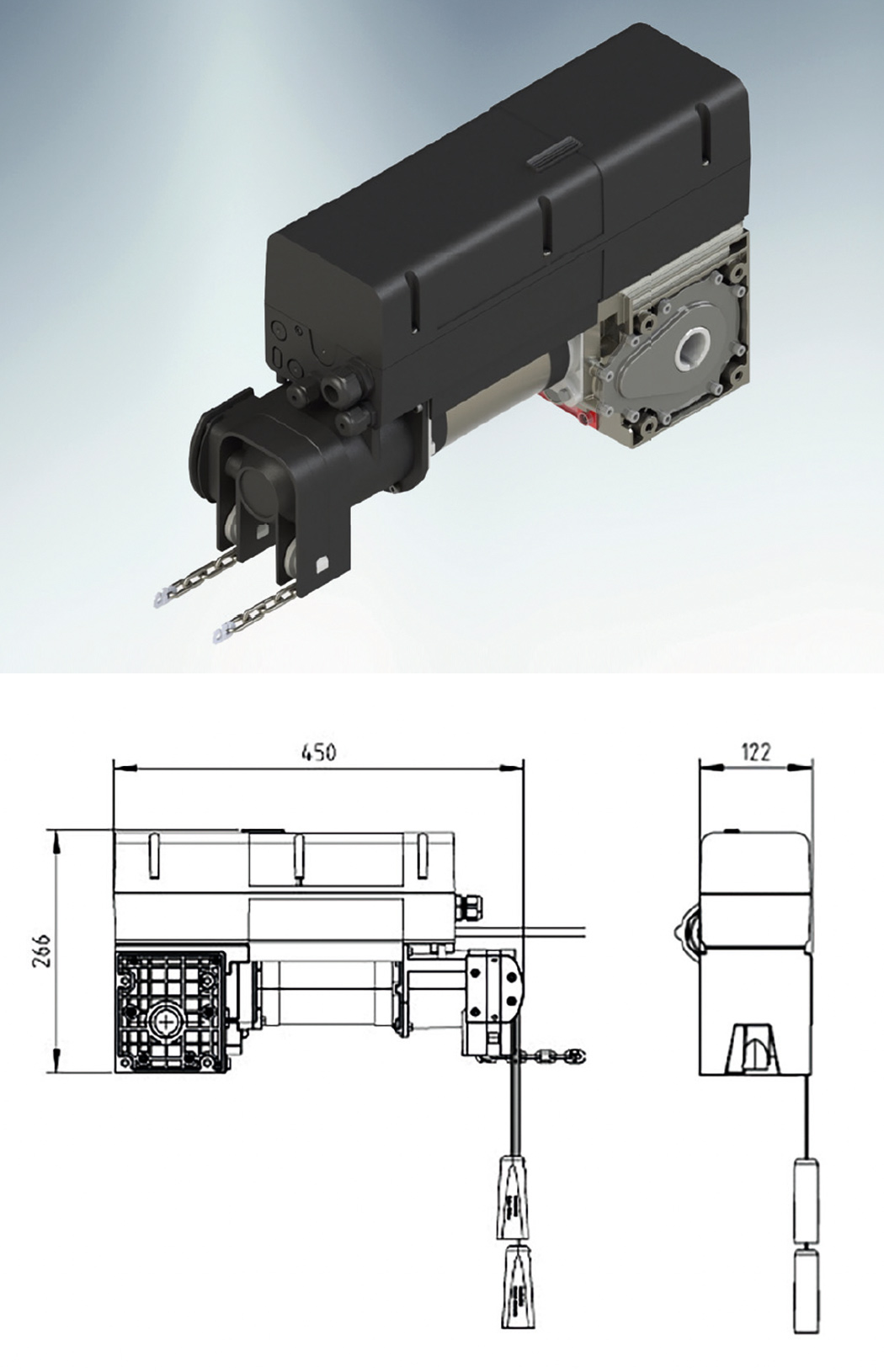

TECHNICAL DATA

TECHNICAL DATA DRIVE

TECHNICAL DATA DRIVE

| DIRECT CURRENT COMMERCIAL 80 NM | DCC 80 |

| Operating voltage | 230 Volt 1-phase connection |

| Operating frequency | 50/ 60 Hz |

| Operating current | 3 A |

| Power output | 330 W |

| Cycles | 15/ hour |

| Output speed | 14 - 30 rpm |

| Output torque | 25 Nm/ max. 80 Nm |

| Holding torque | 250 Nm |

| Maximum revolutions | 15 |

| Protection class | IP 54 |

| Control voltage | 24 V DC |

| Maximum external power supply | 750 mA |

| Shaft diameter | 25.4 mm |

| Weight | 11.5 kg |

TECHNICAL DATA OPERATING UNITS

TECHNICAL DATA OPERATING UNITS

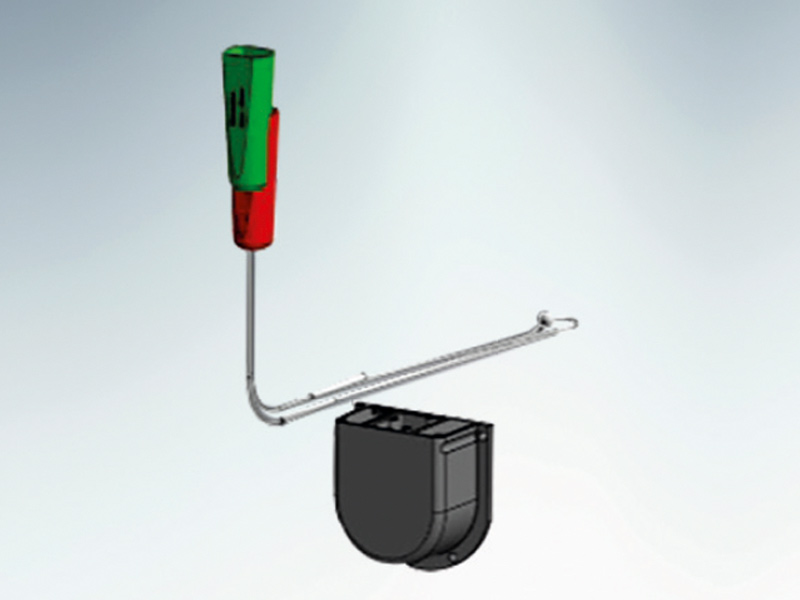

Triple push-button for operating and basic programming of the operator

- Optionally with key switch

Smart triple push-button for operating and conveniently programming the drive

- Extended parameterisation

- Existing safety devices can be connected to the operating unit

- Simple connection with RJ45 plug

- Optionally with key switch

IPD-Easy/ IPD-Smart | |

| Protection class | IP 54 |

| Control voltage | 24 V DC, 200 mA |

| Temperature range | -10 to +50 °C |

| Dimensions H x W x D | 180 x 92 x 45 mm |

| Weight | 0.4 kg |

Installation DCC 80

This video shows you how to install the DCC 80 industrial door operator system from Novoferm in comparison to a standard industrial door operator system.

You can find further animations under:

DIGITAL SOLUTIONS FROM NOVOFERM FOR DOOR AND LOADING SYSTEMS

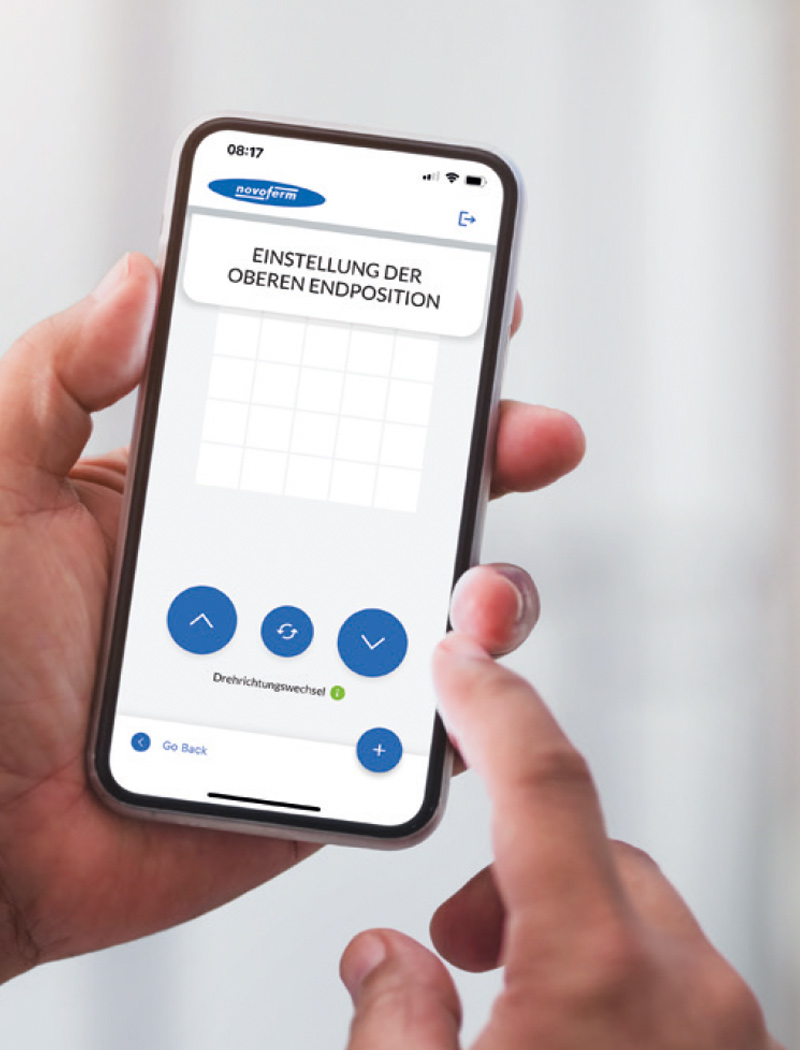

NOVOASSIST APP

NOVOASSIST APP

The smart app/smart assistant for step-by-step commissioning, service and maintenance of door and loading systems simplifies the installation and adjustment of doors, operators and control units for the fitter on site with the following functions:

- Menu-guided commissioning of door systems

- History and error analysis

- Simple adjustments to the setting parameters

- Transfer of the door systems to the NovoServiceHub

- Copy-and-paste function for transferring settings from door to door

- External read access to door systems via app through connection with the NovoServiceHub

- Site-internal parameter transfer to identical door systems

NOVOSERVICEHUB

NOVOSERVICEHUB

The live monitoring solution provides an overview of all installed door and loading systems and allows service and maintenance work to be planned. All products in a system are integrated and can therefore be monitored and managed centrally. Users benefit from many advantages:

- Live monitoring of all door systems and loading stations in a company

- Overview of available error and warning messages and recommendations for action

- Display of current operating data, maintenance intervals and historical change histories

- Operator dashboard with current statuses (door open, closed, etc.) of the door systems as well as local collective messages (errors and pending maintenance)

- Optimised service possible thanks to defined information flow from the control system

- Full-text search for all products, locations and door systems

- Data provision for third-party systems in the future