NOVOFIRE ALUMINIUM-SYSTEME

SYSTEMS FOR DOORS AND WALLS

NovoFire® aluminium profile frame systems are perfect for modern commercial construction. With elegant surfaces, timeless design and numerous variants, they offer ambitious architects and planners almost unlimited possibilities for the design of transparent fire and smoke protection closures in interior areas. Single and double-leaf doors with fanlights and side panels can be combined with each other in a wide variety of ways.

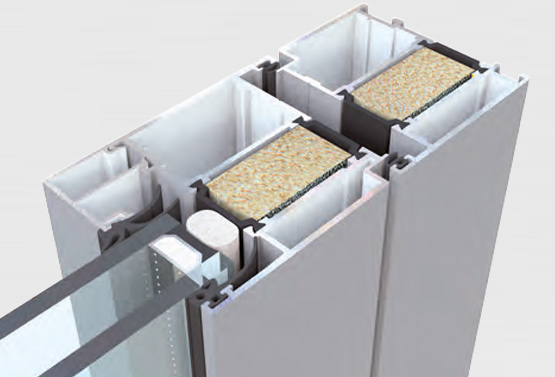

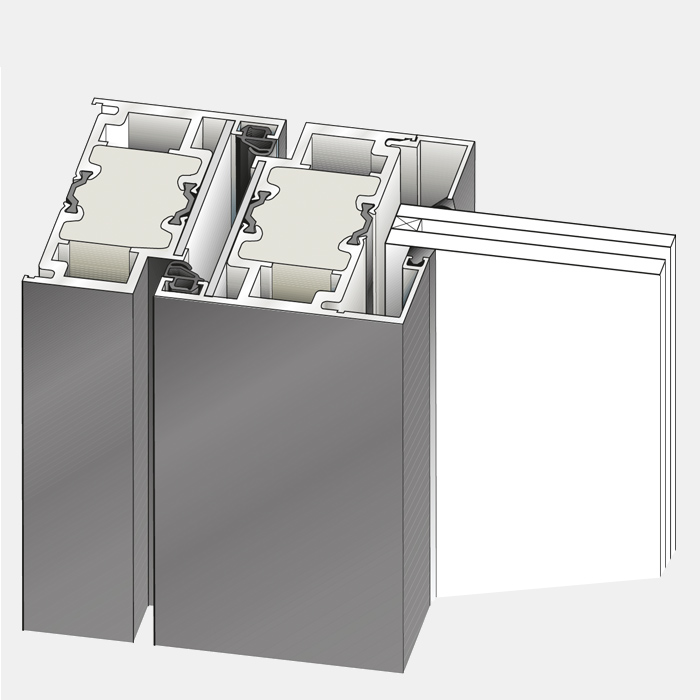

With a profile wall thickness of 4 mm, NovoFire® systems are particularly stable and have an extremely compact design with only one fire protection core anchored in the centre. This results in a standardised face width of 150 mm for all versions. By popular demand, the "anodised aluminium" surface in a stainless steel look is a new addition to the range.

For modern commercial construction

NovoFire aluminium profile frame systems are perfect for modern commercial construction. With a profile wall thickness of 4 mm, the systems are particularly stable and have an extremely compact design with only one fire protection core anchored in the centre. This results in a standardised face width of 150 mm for all versions.

High functionality

Aluminium tubular frame doors are available as fire protection (up to EI2 90), smoke protection, security (up to RC 3) and multi-purpose doors - for a uniform door appearance throughout the building. The Novoferm systems offer a consistent appearance and any combination of single and double-leaf doors, side panels and fanlights.

Many installation advantages

The door series offers numerous installation advantages as well as quick and clean installation procedures. For example, Novoferm fire protection foam can be used to back-fill profiles and frames in metal and drywall construction much more quickly and cleanly. The usual previous knowledge for the installation of fire doors is completely sufficient.

Door comparison and properties

Comparison of aluminum tubular frame doors

| Door designation | Approval / | Frame | T30 | T90 | Smoke | RC 2 | RC 3 | Heat |

| NovoFire RS | P-120003623-10 | aluminium | - | |||||

| NovoFire T30 | Z-6.20-1845 | aluminium | - | - | - | - | ||

| NovoFire F30 | Z-19.14-1769 | aluminium | - | |||||

| NovoFire Thermo EI30 | Performance | aluminium | - | - | - | |||

| NovoFire Glass 30 F30 | Z-19.14-2393 | aluminium | - | |||||

| NovoFire T90 | Z-6.20-1836 | aluminium | - | - | ||||

| NovoFire F90 | Z-19.14-1771 | aluminium | - | |||||

| aluminium Outer door | - | Aluminium | - | - | - |

Highlights aluminum tubular frame doors

Highlights Aluminium tubular frame doors

SYSTEM DESCRIPTION

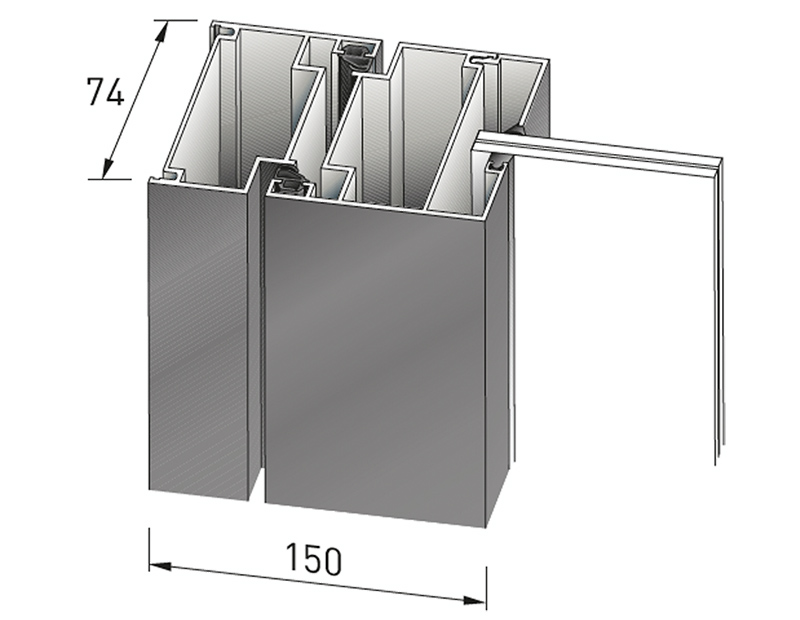

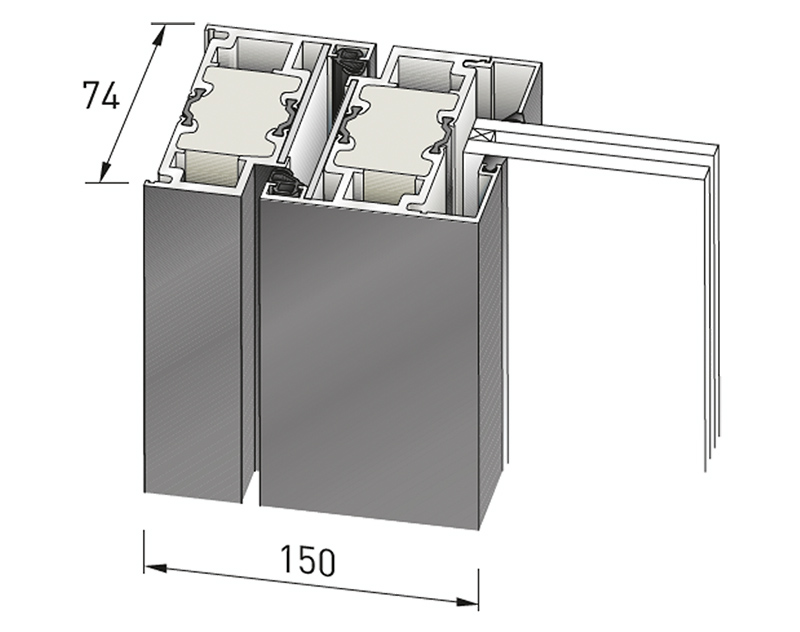

Aluminium door element made of single-chamber hollow profiles. The door is tested as a smoke protection door using an automatically lowerable floor seal in accordance with DIN 18095. Face width of frame and sash 150 mm, plinth height 98-238 mm, installation depth 74 mm (T30) or 90 mm (T90). The leaf dimension of the inactive leaf must not be less than 500 mm for double-leaf doors. Elements prepared for installation.

FITTINGS

Drop-in lock, prepared for profile cylinder, lever handle or interchangeable fittings with oval rosette in aluminium, stainless steel or PVC-U possible. The inactive leaf is held by the upper locking mechanism with a rebate shoot bolt, alternatively anti-panic function to DIN EN 179 or DIN EN 1125 possible. Slide channel overhead door closer to DIN EN 1154, integrated door locking systems for RS and T30, swing door drive to DIN 18263/ DIN 18650.

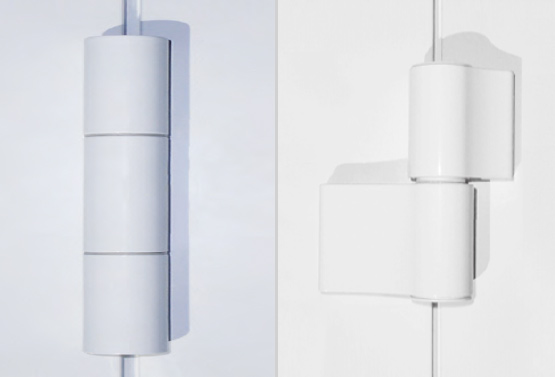

Hinges

Two 2-part aluminium screw-on hinges per leaf, adjustable in three dimensions; 3 hinges are required if the door is fitted with a swing door drive. Roller hinges are also available on request instead of screw-on hinges.

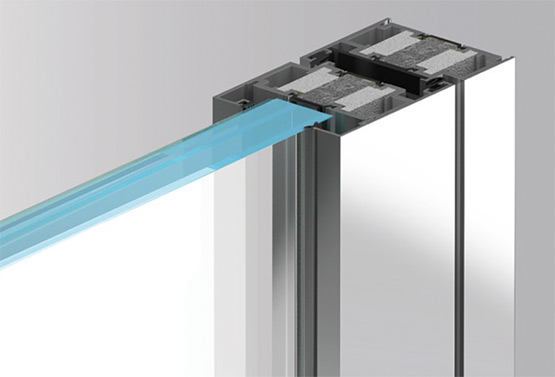

GLAZING

Safety glass VSG or ESG. Glazing variants and panel infills, profiles with one-sided glazing rebate and glass retaining strips on the opposite hinge side, dry glazing with EPDM seals.

FIXED GLAZING

Flush connections to the door, alternatively stand-alone possible, optionally bevelled or T-connections. The frame uprights must run uninterrupted over the entire height of the fire-resistant glazing.

SURFACE

- Standard:

Powder-coated, final paint finish, satin gloss (RAL Classic of your choice) - Optional:

Anodised, stainless steel look, powder-coated in wood decor, NCS colours

Colours and optional extras

Colours and optional extras

TUBULAR FRAME DOORS WITH SPECIAL FEATURES MAKE SMOKE AND FIRE PROTECTION MORE ATTRACTIVE

Tested smoke and fire protection is the basis, but special features characterise the design. This is exactly what makes NovoFire® a series of many possibilities. Whether wood decor and feel or tinted glass in various colours, the system can be integrated into any architectural concept with an individual configuration.

FITTINGS

Drop-in lock, prepared for profile cylinder, lever handle or interchangeable fittings with oval rosette in aluminium, stainless steel or PVC-U possible. Inactive leaf held by the top locking mechanism of the active leaf as standard, alternatively anti-panic function in accordance with DIN EN 179 or DIN EN 1125 possible.

DESIGNING WITH INNOVATIVE ELEMENTS

The NovoFire® tubular frame doors offer planners and building owners the very best conditions for a skilful interplay of shapes, surfaces and materials. For example, with a wood decor that is virtually indistinguishable from real wood thanks to its textured surface. Other metallic-look decors and tinted glazing open up highly customised solutions in the spectrum between technical-cool and natural-noble.

Hinges

Only two 3-part roller hinges per leaf up to a door height of 2.50 m, adjustable in two dimensions; if the door is fitted with a swing door drive, we recommend three hinges. Other hinge variants such as screw-on hinges (three-dimensionally adjustable) are possible.

ATTRACTIVE SURFACES

- Anodised aluminium, stainless steel look or powder-coated finish (RAL Classic of your choice)

- Powder-coated steel, primed RAL 9002 (grey-white) or optionally final painted (RAL Classic of your choice)

- Decorative looks and haptics of natural materials such as wood

Details NovoFire aluminium systems for doors and walls

Details NovoFire aluminium systems for doors and walls

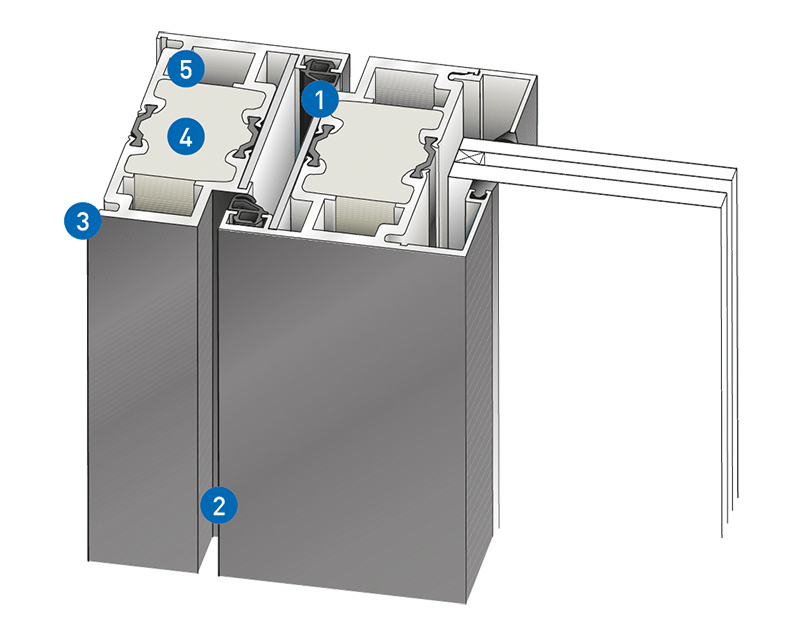

ROHRRAHMENTÜREN NOVOFIRE®

MERKMALE

[1 ] The door rebate is clad on three sides with smooth and black PVC-coated fire protection strips

[3 ] Flush doors for high aesthetic standards with RS, T30 (EI 30) and T90 (EI 90)

[3 ] 4 mm wall thickness for particularly high stability

[4 ] Only one fire protection core

[5 ] The outer chambers are free and can be used for attaching add-on parts

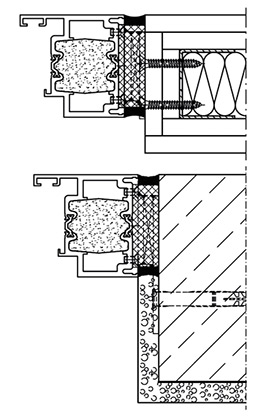

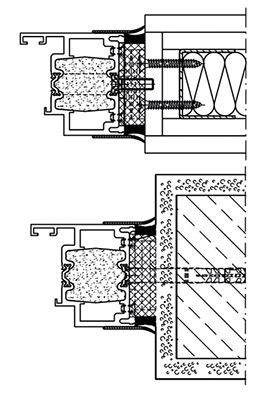

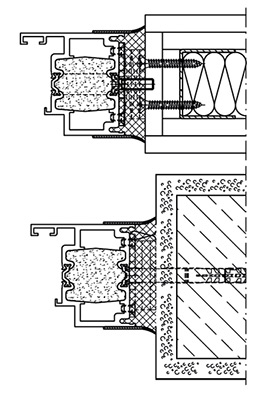

CROSS CUTS

Whether noise protection, fire protection T 30 or T 90:

The NovoFire® tubular frame door presents itself with the same professional finishes for a uniform look throughout the building.

BAND VARIANTS

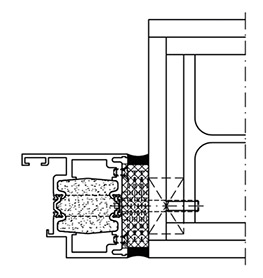

Details Aluminium exterior doors

Details Aluminium exterior doors

ALUMINIUM EXTERIOR DOOR- SAVING ENERGY IS NOT A MATERIAL

The aluminium exterior door is a stable profile system for highly thermally insulated door systems at side and rear entrance areas in industrial, commercial and administrative buildings. It therefore also covers secondary areas and complements the rest of the Novoferm door programme in an advantageous way. The external door also impresses with its good technical properties, outstanding Uƒ values and numerous design options.

Hinges

Suitable for the installation of all commercially available fittings. Several door hinge variants are available, from sturdy screw-on hinges to completely concealed door hinges and roller hinges in aluminium or stainless steel.

CONSTRUCTION

Sturdy frame/sash combination with 2 mm wall thickness. Sash profiles can optionally be fitted with sliding insulating bars to minimise the bimetal effect.

DOOR SILL

The barrier-free threshold variant with 19 mm installation height and concealed fixing ensures a visually smooth transition from outside to inside and can be used in old and new buildings thanks to a special base profile.

PROFILE DIMENSIONS

The profiles and profile dimensions specified below are minimum requirements. However, it is possible that reinforced profiles may be used for structural reasons.

Profile construction depths:

- Frame, glazing bars, transom 75 mm

- Sash frame (door) 75 mm

Profile face widths, door: (standardised for the NovoFire® fire protection system)

- Door frame incl. door leaf 149 mm

- Door plinth 150 mm

Details Aluminium exterior doors Thermo

Details Aluminium exterior doors Thermo

NOVOFIRE® THERMO ALU/FIRE PROTECTION DOOR FOR EXTERIOR

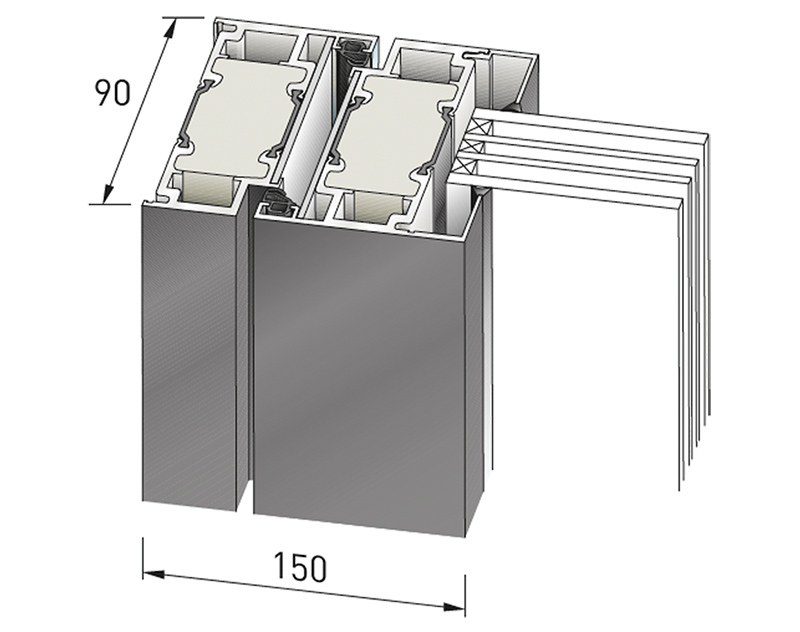

The system is based on stable NovoFire® hollow profiles with 4 mm wall thickness, with a construction depth of 90 mm, also suitable for generous clear passage dimensions. The 30-minute fire resistance time and high thermal insulation properties of the construction are achieved by inserting a fire protection insulator developed by Novoferm.

Customised building safety requirements can be realised by combining equipment components.

DESCRIPTIONS

Maximum flexibility and compatibility for hardware and accessories. Components can be selected to suit the application. The sturdy two-part screw-on hinges are available in different colours: E6/EV1 = standard, RAL of your choice and in stainless steel look.

CONSTRUCTION

Sturdy frame/sash combination with 4 mm wall thickness. High insulation in case of fire EI130 C5.

DOOR SILL

The barrier-free threshold variant with 19 mm installation height and concealed fixing ensures a visually smooth transition from outside to inside and can be used in old and new buildings thanks to a special base profile.

ROFILE DIMENSIONS

The profile dimensions are identical in appearance to the NovoFire fire and smoke protection system.

- Profile construction depth: 90 mm

- Profile face width: 150 mm

- Door frame incl. door leaf

- Door plinth: 98 mm

Your plus points at a glance

- Smoke tightness according to DIN 18095

- Fire resistance classes T30 (EI2 30) / F30 or T90 (EI2 90) / F90 in accordance with DIN 4102

- Burglar resistance in accordance with DIN EN V1627 for T30 (EI2 30) doors in classes RC1 (WK1) or RC2 (WK2), optionally also RC3 (WK3)

- Single or double-leaf smoke/fire doors can be combined with fixed elements in any muntin bar arrangement up to 4.0 m (F90) or 5.0 m (F30) high

- Overhead door closers, electric strikes or anti-panic functions in accordance with DIN EN 179 or DIN EN 1125 can be integrated

- All systems have the same appearance throughout and doors, side panels and fanlights can be combined as required

- Frame and door profile are flush with each other

- Numerous application options and maximum design freedom

Technology and details

Technical data smoke protection tubular frame doors

Technical data smoke protection tubular frame doors

| Resistance class | Smoke protection | |||||

| Type designation | NovoFire® Alu | NovoFire® aluminium | NovoFire® | NovoFire® RS door | ||

| Element division | ||||||

| Slopes | - | - | - | - | ||

| Round arches | - | - | - | - | ||

| Recesses | - | - | - | - | ||

| angle | - | - | - | - | ||

| Widenings | - | - | - | - | ||

| Dimensions | ||||||

| Overall dimensions | Width min. - max. | 624 - 1834* | no specifications | 1500 - 3270* | unlimited | |

Height min. - max. | 1750 - 3135* | no specifications | 1755 - 3135* | max. 5015 ¹)²) | ||

| Outer frame dimension | Width min. - max. | 604 - 1804* | 621 - 1821* | 1470 - 3240* | unlimited | |

Height min. - max. | 1740 - 3120* | 1749 - 3129* | 1740 - 3120* | max. 5000 ¹)²) | ||

| Disc size | Width min. - max. | 454 - 1414 | 454 - 1414 | 1320 - 2850 | - | |

Height min. - max. | 1665 - 2925 | 1665 - 2925 | 1665 - 2925 | - | ||

| Door leaf | ||||||

| Construction depth | 74 | 74 | 74 | 74 | ||

| View | 150 | 159 | 150 | 75 | ||

| Plinth height | 98 - 238 | 98 - 238 | 98 - 238 | 75 - 225 | ||

| Transom profile | 98 | 98 | 98 | 98 | ||

| Glued rung | 20 - 140 | 20 - 140 | 20 - 140 | 20 - 140 | ||

| Walls | ||||||

| Masonry | ≥ 115 | ≥ 115 | ≥ 115 | ≥ 115 | ||

| Concrete | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | ||

| Aerated concrete block or plane blocks | ≥ 175 | ≥ 175 | ≥ 175 | ≥ 175 | ||

| Aerated concrete slabs | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | ||

| Stud walls Transoms and Steel studs | ≥ 95 | ≥ 95 | ≥ 95 | ≥ 95 | ||

| Stud walls Transoms and Wooden studs |

|

|

|

| ||

| Clad and unclad steel component | - | - | - | - | ||

| clad wood component | - | - | - | - | ||

| Combination door/ glazing | - | - | - | - | ||

| Z-frame | - | - | - | - | ||

| Fillings | ||||||

| Glazing thickness | 1302 x 2782 | 1302 x 2782 | 1302 x 2782 | - | ||

| panel | - | - | - | - | ||

| Glass / Panel | - | - | - | - | ||

| Glass insert | Wet glazing | - | - | - | - | |

Dry glazing | - | - | - | - | ||

| Design variants | ||||||

| with fanlight and side panel | - | - | - | - | ||

| with fanlight | - | - | - | - | ||

| with side panel | - | - | - | - | ||

| Smoke protection door according to DIN 18095 and DIN EN 1634 - Part 3 | - | - | - | - | ||

| Sound insulation design maximum Rw,P (Rw,R) | 42 (37) | - | 42 (37) | - | ||

| Burglar resistance ³) | - | - | - | - | ||

| Thermal transmittance Uf | - | - | - | - | ||

| Test certificate/ Approval numbers | P-120003623-10 | P-120003623-10 | P-120003623-10 | P-120003623-10 | ||

| Tested according to | DIN 4102 and DIN EN 1634 | |||||

| - possible - not possible * incl. frame widening of the door on the left, right and at a height of 120 mm ¹) according to static requirements ²) Installation of the RS-1 door or RS-2 door in the fixed glazing: We recommend a stiffening tube on the left and right of the frame profile of the fixed glazing. H < 3500 without stiffening tube, H < 4000 with aluminium tube 80 x 50 x 4, H < 4500 with aluminium tube 100 x 50 x 4.tube 80 x 50 x 4, H < 4500 with aluminium tube 100 x 50 x 4, H < 5000 with aluminium tube 120 x 50 x 4 ³) Possible based on the "System NovoFire® T30" system | ||||||

| All dimensions in mm, RAM = external frame dimension | ||||||

Technical data T30 (EI 30) fire-resistant tubular frame doors

Technical data T30 (EI 30) fire-resistant tubular frame doors

| Resistance class | T30 (EI2 30) / F30 | |||||

| Type designation | NovoFire® aluminium | NovoFire® aluminium | NovoFire® | NovoFire® F30 with T30 | ||

| Element division | ||||||

| Sloping | - | - | - | - | ||

| Round arches | - | - | - | - | ||

| Recesses | - | - | - | - | ||

| angle | - | - | - | - | ||

| Widenings | - | - | - | - | ||

| Dimensions | ||||||

| Overall dimensions | Width min. - max. | 634 - 1834* | 811 - 3312* | 1500 - 3270* | unlimited | |

Height min. - max. | 1750 - 3135* | 1915 - 3820* | 1755 - 3135* | max. 5015 ¹)²) | ||

| Outer frame dimension | Width min. - max. | 604 - 1804* | 781 - 3282* | 1470 - 3240* | unlimited | |

Height min. - max. | 1740 - 3120* | 1900 - 3805* | 1740 - 3120* | max. 5000 ¹)²) | ||

| Clear passage with 180° opening | Width min. - max. | 454 - 1414 | 454 - 1414 | 1320 - 2850 | - | |

Height min. - max. | 1665 - 2925 | 1665 - 2616 | 1665 - 2925 | - | ||

| Door leaf | ||||||

| Construction depth | 74 | 74 | 74 | 74 | ||

| View | 150 | 159 | 150 | 75 | ||

| Plinth height | 98 - 238 | 98 - 238 | 98 - 238 | 75 - 225 | ||

| Transom profile | 98 | 98 | 98 | 98 | ||

| Glued rung | 20 - 140 | 20 - 140 | 20 - 140 | 20 - 140 | ||

| Walls | ||||||

| Masonry | ≥ 115 | ≥ 115 | ≥ 115 | ≥ 115 | ||

| Concrete | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | ||

| Aerated concrete block or plane blocks | ≥ 175 | ≥ 175 | ≥ 175 | ≥ 175 | ||

| Aerated concrete slabs | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | ||

| Stud walls Transoms and Steel studs | ≥ 95 | ≥ 95 | ≥ 95 | ≥ 95 | ||

| Stud walls transoms and Timber studs |

|

|

|

| ||

| Clad and unclad steel component | - | - | - | - | ||

| clad wood component | - | - | - | - | ||

| Combination door/ glazing | - | - | - | - | ||

| Z-frame | - | - | - | - | ||

| Fillings | ||||||

| Contrafl am 30 - 1 / Contrafl am 30 - V6 (Contrafl am 30 - V22) / Contrafl am 30 - V24 (Contrafl am 30 - V26) / Contrafl am 30 IGU max. width x height | 1302 x 2782 | 2200 x 1400 | ||||

| Pyrostop type 30 - 1 / Pyrostop type 30 - 10 / Pyrostop type 30 - 2 / Pyrostop type 30 - 20 / +P2A, P4A, P6B / Pyrostop 30 - 1.Iso / Pyrostop 30 - 2.Iso max. width x height Width x height | 1400 x 2577 | 2929 x 924 | ||||

| Promaglas 30, type 1 / Promaglas 30, type 2 / Promaglas 30, type 20 | 1302 x 2782 | 1302 x 2782 | ||||

| Panel | - | - | - | - | ||

| Glass / Panel | - | - | - | - | ||

| Glass insert | Wet glazing | - | - | - | - | |

Dry glazing | - | - | - | - | ||

| Design variants | ||||||

| with fanlight and side panel | - | - | - | - | ||

| with fanlight | - | - | - | - | ||

| with side panel | - | - | - | - | ||

| Smoke protection door according to DIN 18095 and DIN EN 1634 - Part 3 (in combination with DIN 4102) | - | - | - | - | ||

| Sound insulation design maximum Rw,P (Rw,R) | 40 (35) | - | 40 (35) | - | ||

| Burglar resistance ³) | WK 1-3 | WK 1-3 | - | - | ||

| Thermal transmittance Uf | - | - | - | - | ||

| Test certificate/ Approval numbers | Z-6.20-1845 | Z-6.20-1845 | Z-6.20-1845 | Z-19.14-1769 | ||

| Tested according to | DIN 4102 and DIN EN 1634 | |||||

| - possible - not possible * incl. frame widening of the door on the left, right and at a height of 120 mm ¹) according to static requirements ²) Installation of the RS-1 door or RS-2 door in the fixed glazing: We recommend a stiffening tube on the left and right of the frame profile of the fixed glazing. H ≤ 3500 without stiffening tube, H ≤ 4000 with aluminium tube 80 x 50 x 4, H ≤ 4000 with aluminium tube 80 x 50 x 4, tube 80 x 50 x 4, H ≤ 4500 with aluminium tube 100 x 50 x 4, H ≤ 5000 with aluminium tube 120 x 50 x 4 ³) Possible based on the "System NovoFire® T30" system | ||||||

| All dimensions in mm, RAM = external frame dimension | ||||||

Technical data T90 (EI 90) fire-resistant tubular frame doors

Technical data T90 (EI 90) fire-resistant tubular frame doors

| Resistance class | T90 (EI2 90) / F90 | ||||||

| Type designation | NovoFire® aluminium | NovoFire® aluminium | NovoFire® F90 with T90 | ||||

| Element layout | |||||||

| Slopes | - | - | - | ||||

| Round arches | - | - | - | ||||

| Recesses | - | - | - | ||||

| angle | - | - | - | ||||

| Widenings | - | - | - | ||||

| Dimensions | |||||||

| Overall dimensions | Width min. - max. | 634 - 1834* | 1500 - 2730* | unlimited | |||

Height min. - max. | 1750 - 3135* | 1750 - 2610* | max. 4015 ¹)²) | ||||

| Outer frame dimension | Width min. - max. | 604 - 1710* | 1470 - 2700* | unlimited | |||

Height min. - max. | 1740 - 2600* | 1740 - 2600* | max. 4000 ¹)²) | ||||

| Clear passage with 180° opening | Width min. - max. | 454 - 1320 | 1320 - 2310 | - | |||

Height min. - max. | 1665 - 2405 | 1665 - 2405 | - | ||||

| Door leaf | |||||||

| Construction depth | 90 | 90 | 90 | ||||

| View | 150 | 150 | 75 | ||||

| Plinth height | 98 - 238 | 98 - 238 | 98 - 238 | ||||

| Transom profile | 98 | 98 | 98 | ||||

| Glued rung | 20 - 140 | 20 - 140 | 20 - 140 | ||||

| Walls | |||||||

| Masonry | ≥ 175 | ≥ 175 | ≥ 175 | ||||

| Concrete | ≥ 140 | ≥ 140 | ≥ 140 | ||||

| Aerated concrete block or plane blocks | ≥ 200 | ≥ 200 | ≥ 200 | ||||

| Aerated concrete slabs | ≥ 175 | ≥ 175 | ≥ 175 | ||||

| Stud walls transoms and Steel studs | ≥ 100 | ≥ 100 | ≥ 100 | ||||

| Stud walls transoms and studs made of wood | - | - | - | ||||

| Clad and unclad steel component | - | - | - | ||||

| clad wood component | - | - | - | ||||

| Combination door/ glazing | - | - | - | ||||

| Z-frame | - | - | - | ||||

| Fillings | |||||||

| Contraflam 90 | Width x height max. | 1208 x 2261 | 1208 x 2261 | ||||

| Skylight | 2347 x 939 |

1400 x 2400

1400 x 2400

1400 x 2400 | |||||

| Side panel | 939 x 2413 | ||||||

| Pyrostop type 90-1 | Width x height | 1208 x ≤ 2261 | 1208 x 2261 | ||||

| Total area | ≤ 2,44 m² | ≤ 2,44 m² | |||||

| Skylight | 2347 x 939 | ||||||

| Side panel | 939 x 2413 | ||||||

| Pyrostop type 90-2 | Width x height | 1208 x ≤ 2261 | 1208 x 2261 | ||||

| Total area | ≤ 2,44 m² | ≤ 2,44 m² | |||||

| Skylight | 2347 x 939 | ||||||

| Side panel | 939 x 2413 | ||||||

| Panel | - | - | - | ||||

| Glass / Panel | - | - | - | ||||

| Glass insert | Wet glazing | - | - | - | |||

Dry glazing | - | - | - | ||||

| Design variants | |||||||

| with fanlight and side panel | - | - | - | ||||

| with fanlight | - | - | - | ||||

| with side panel | - | - | - | ||||

| Smoke protection door according to DIN 18095 and DIN EN 1634 - Part 3 (in combination with DIN 4102) | - | - | - | ||||

| Sound insulation design maximum Rw,P (Rw,R) | 42 (37) | 42 (37) | - | ||||

| Burglar resistance ³) | WK 1-3 | WK 1-3 | - | ||||

| Thermal transmittance Uf | - | - | - | ||||

| Test certificate/ Approval numbers | Z-6.20-1845 | Z-6.20-1836 | Z-19.14-1771 | ||||

| Tested according to | DIN 4102 and DIN EN 1634 | ||||||

| - possible - not possible * incl. frame widening of the door on the left, right and at a height of 120 mm ¹) according to static requirements ²) Installation of the RS-1 door or RS-2 door in the fixed glazing: We recommend a stiffening tube on the left and right of the frame profile of the fixed glazing. H ≤ 3500 without stiffening tube, H ≤ 4000 with aluminium tubetube 80 x 50 x 4, H ≤ 4500 with aluminium tube 100 x 50 x 4, H ≤ 5000 with aluminium tube 120 x 50 x 4 | |||||||

| All dimensions in mm, RAM = external frame dimensions | |||||||

Technical data security tubular frame doors RC 2 / RC 3

Technical data security tubular frame doors RC 2 / RC 3

| Resistance class | RC 2 | RC 3 | ||||

| Type designation | NovoFire® T30 | NovoFire® T30 | NovoFire® T30 | |||

| Dimensions | Overall dimensions | Width min. - max. | 1080 - 1485 | 1080 - 1485 | 1840 - 2530 | |

| Height min. - max. | 1840 - 2530 | 1840 - 2530 | 1840 - 2530 | |||

| Frame depth | Installation depth | 74 | 74 | 74 | ||

| View width frame profile | 75 | 75 | 75 | |||

| Walls (thickness without plaster) | Masonry/ exposed brickwork (brick strength 12/ mortar group II) | ≥ 115 | ≥ 115 | ≥ 115 | ||

| Concrete (B15) | ≥ 100 | ≥ 120 | ≥ 120 | |||

| Aerated concrete (compressive strength ≥ 4/ bonded) | ≥ 170 | ≥ 240 | ≥ 240 | |||

| Clad steel component min. F60-A | - | - | - | |||

| Fillings | Glass with safety properties F30 | P4A Thickness ≥ 21 | P5A thickness ≥ 21 | P5A thickness ≥ 21 | ||

- | P6B Thickness ≥ 21 | P6B Thickness ≥ 21 | ||||

| Panel with safety properties F30 | 2x sheet steel, fire protection core | 2x sheet steel, fire protection core | 2x sheet steel, fire protection core | |||

| Safety equipment | Number of safety pins | 3 | 3 | 3 | ||

| Drop-in deadbolt lock with spring-loaded lock attachment with top locking | - | - | - | |||

| Mortise deadbolt lock with top locking | - | - | - | |||

| Multi-point lock | - | - | - | |||

| Multi-point lock with A-opener | - | - | - | |||

| E-opener 1) | - | - | - | |||

| Security locking cylinder in accordance with EN 1303 Class 4 or DIN 18252 Class 21, 31, 71 BZ | The length of the locking cylinder is: Door leaf thickness 74 mm + the thickness of the protective fitting, the locking cylinder must not protrude more than 3 mm beyond the door plate | |||||

| Interchangeable set, DIN 18257/ ES 1 long plate | - | - | - | |||

| Lever handle set, DIN 18257/ ES 1 long plate | - | - | - | |||

| lever handle set, DIN 18257/ ES 3 long plate | - | - | - | |||

| Lever handle set, DIN 18257/ ES 3 long plate | - | - | - | |||

| Panic function to EN 179 | - | - | - | |||

| Panic function to EN 1125 with push bar (touch bar) | - | - | - | |||

| Panic function according to EN 1125 with pushbar | - | - | - | |||

| Panic function B (switch function for lever handle set) | - | - | - | |||

| Panic function D (passage function for lever handle set) | - | - | - | |||

| Panic function E (change function for lever handle set) | - | - | - | |||

| Roller hinge | - | - | - | |||

| Screw-on hinge 2-part 3D with hinge lock | - | - | - | |||

| Concealed hinges | - | - | - | |||

| Magnetic contacts | - | - | - | |||

| Bolt contacts | - | - | - | |||

| Overhead door closer | - | - | - | |||

| Concealed door closer | - | - | - | |||

| Threshold for door with escape function | No 2) | No 2) | No 2) | |||

| Glazing | Dry glazed | - | - | - | ||

| Wet glazed | - | - | - | |||

| Glazing bead clamped or clipped in | - | - | - | |||

| Glazing bead screwed | - | - | - | |||

| Additional functions | Fire protection | T30-1 | T30-1 | T30-2 | ||

| Smoke protection | - | - | - | |||

| Sound insulation depending on equipment up to (Rw) | Up to 40 dB | Up to 40 dB | Up to 40 dB | |||

| Tested according to | DIN EN 1627 | |||||

- possible - not possible 1 ) Electric strike in combination with the main lock is not permitted. 2 ) When combined with a panic push bar (touch bar), a threshold is not required. | ||||||

Technical data aluminium external closures

| Resistance class | Thermally insulated external closures | ||||

| Type designation | 1-leaf door | 2-panel door | Glazing | ||

| Element layout | |||||

| Slopes | - | - | - | ||

| Round arches | - | - | - | ||

| Recesses | - | - | - | ||

| angle | - | - | - | ||

| Widenings | - | - | - | ||

| Dimensions | |||||

| Overall dimensions | Width min. - max. | 625 - 1450 | 1500 - 2400 | unlimited | |

Height min. - max. | 1750 - 2505 | 1750 - 2400 | 5000 ¹) | ||

| Outer frame dimension | Width min. - max. | 605 - 1425 | 1470 - 2395 | unlimited | |

Height min. - max. | 1740 - 2495 | 1740 - 2385 | 5000 ¹) | ||

| Clear passage with 180° opening | Width min. - max. | 461 - 1281 | 1322 - 2247 | - | |

Height min. - max. | 166 - 2417 | 1668 - 2313 | - | ||

| Door leaf | |||||

| Construction depth | 75 | 75 | 75 | ||

| View | 149 | 149 | 74 | ||

| Plinth height | 152 | 152 | 176 | ||

| Transom profile | 76 - 96 | 76 - 96 | 76 - 96 | ||

| Glued rung | 20 - 140 | 20 - 140 | 20 - 140 | ||

| Walls | |||||

| brickwork | - | - | - | ||

| concrete | - | - | - | ||

| Aerated concrete block or flat blocks | - | - | - | ||

| Aerated concrete slabs | - | - | - | ||

| Stud walls | - | - | - | ||

| Clad steel component | - | - | - | ||

| clad wood component | - | - | - | ||

| Combination door/ glazing | - | - | - | ||

| Z-frame | - | - | - | ||

| Fillings | |||||

| Glazing thickness 4) | 24-52 mm | ||||

| Panel | - | - | - | ||

| Glass / Panel | - | - | - | ||

| Glass insert | Wet glazing | - | - | - | |

Dry glazing | - | - | - | ||

| Design variants | |||||

| with fanlight and side panel | • | - | - | ||

| with fanlight | - | - | - | ||

| with side panel | - | - | - | ||

| Joint permeability class | 4 | 4 | 4 | ||

| Driving rain tightness class | up to 6 A | up to 6 A | - | ||

| Sound insulation | 40 dB | 40 dB | 40 dB | ||

| Burglar resistance | WK 2 | WK 2 | - | ||

| Thermal transmittance Uf | 1.3 - 1.9 W/m²K | 1.3 - 1.9 W/m²K | 1.3 - 1.9 W/m²K | ||

| CE labelling according to EN 14351-1 | - | - | - | ||

| Tested according to | DIN 4102 and DIN EN 1634 | ||||

- possible - not possible ¹) according to static requirements ²) No façade, no tilt and turn windows ³) Other sizes possible 4) All commercially available glass types are available | |||||

| All dimensions in mm, RAM = external frame dimension | |||||

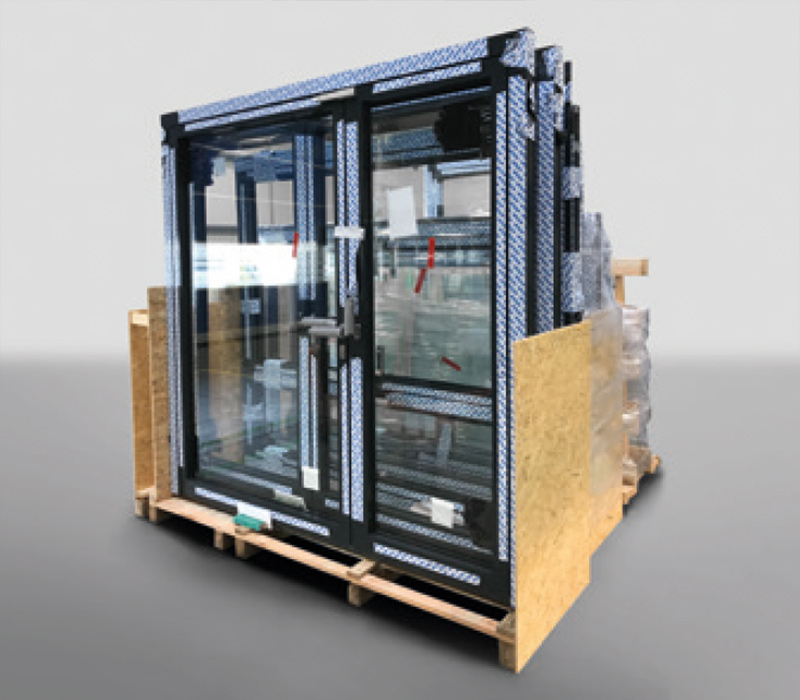

Montage

SIMPLE ASSEMBLY AND FAST FRAME BACKFILLING

The following is a step-by-step video showing you how to install a Novoferm tubular frame door and the options for backfilling the frame with Novoferm fire protection foam. The videos and information are only intended as a supplement to the installation, operating and maintenance instructions. They do not replace professional installation by qualified and trained specialist personnel.

INSTALLATION NOVOFERM TUBULAR FRAME DOOR

In this video from the area of doors and tubular frame doors, Novoferm illustrates the installation of a tubular frame door using the example of a NovoFire® Alu T30 with the individual installation steps visually in detail.

You can find more videos on the Novoferm YouTube channel:

https://www.youtube.com/NovofermVideos

Factory pre-assembly and delivery

Factory pre-assembly and delivery

Novoferm fire protection foam

Novoferm fire protection foam

INSTALL DOORS QUICKLY WITH NOVOFERM FIRE PROTECTION FOAM

With Novoferm fire protection foam, profiles and frames in metal and drywall construction can be backfilled much more quickly and cleanly. The usual prior knowledge for the installation of fire doors is completely sufficient. Documenting the approval-compliant installation is extremely simple. For this purpose, there are easily removable self-adhesive labels 1 on the foam can, which are simply stuck onto the confirmation of conformity 2 and contain all the necessary information.

There is no simpler, cleaner and quicker way to install fire doors today.