NOVOFERM PROFILE FRAME SYSTEMS MADE OF STEEL

NEU - NOVOFIRE STEEL

With NovoFire® Steel, Novoferm is launching the first steel tubular frame door developed and manufactured in-house that is approved as a fire and smoke protection closure. The new door impresses with its many advantages: The innovative profile geometry enables elegant design and great flexibility in terms of construction, glazing, fittings and retrofitting with other approved components. The system is also characterised by simple installation and scores highly in terms of sustainability, as it is based on recyclable steel.

For modern property construction

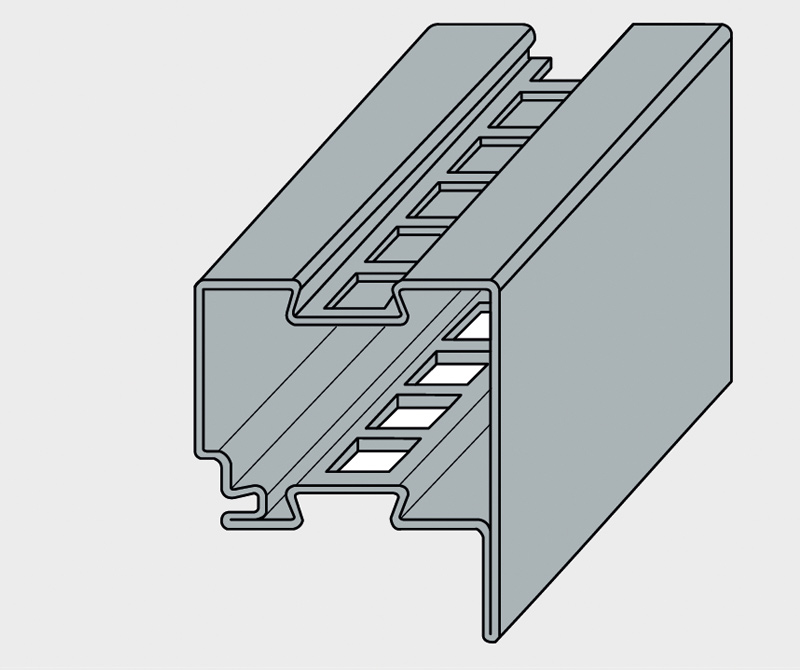

NovoFire® Steel tubular frame doors are based on steel profiles with a construction depth of 65 mm and a material thickness of 1.8 mm. The series is characterised by reliable fire and/or smoke protection as well as a wide range of application options, flexible configuration and simple installation

High functionality

Available as a NovoFire® Steel T30 fire door (EI 30 S200 C5) and as a NovoFire® Steel RS smoke control door (S200). Our doors offer easy installation and fine adjustment with well thought-out details (including a unique multifunctional groove for easy installation and fine adjustment of fittings, etc.).

Living sustainability

The basic profile of Novoferm tubular frame doors is made of 100% recyclable steel and is always flush-mounted. The door can also be easily retrofitted with various components. This allows the system to be subsequently adapted to changing requirements.

Door comparison and properties

Comparison of steel tubular frame doors

| Door designation | Approval / | Frame | T30 | T90 | Smoke | RC 2 | RC 3 | Heat |

| NovoFire Steel RS | P-5022 DMT DO | steel | - | |||||

| NovoFire Steel T30 | - | Steel | - | - | ||||

| NovoFire Steel F30 | - | Steel | - | |||||

| Forster fuego T90 | Z-6.20-1881 | steel | - | - | ||||

| Forster fuego F90 | Z-19.14-1973 | steel | - | |||||

| Forster unico | - | steel | - | - | - | |||

| Forster unico EI30 | Performance | steel | - | - | - |

Details NovoFire Steel

Details NovoFire Steel

THAT NOVOFIRE® HANDLE

NOVOFIRE® STEEL T30 AND NOVOFIRE® STEEL RS

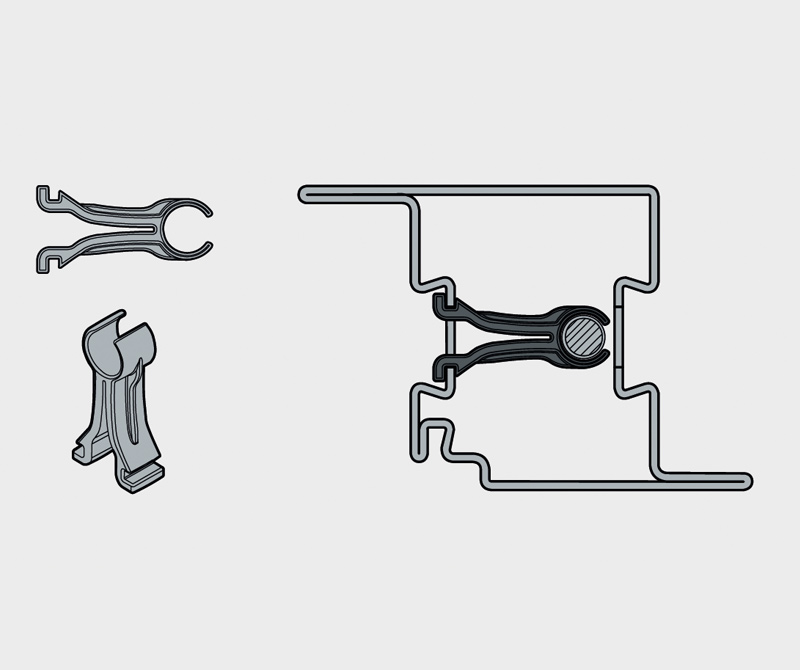

NovoFire® Steel tubular frame doors are based on steel profiles with a construction depth of 65 mm and a material thickness of 1.8 mm. The series is characterised by reliable fire and/or smoke protection as well as a wide range of application options, flexible configuration and simple installation. Available as a NovoFire® Steel T30 (EI 30 S200 C5) fire protection door and as a NovoFire® Steel RS (S200) smoke protection door, NovoFire® Steel fulfils various safety requirements.

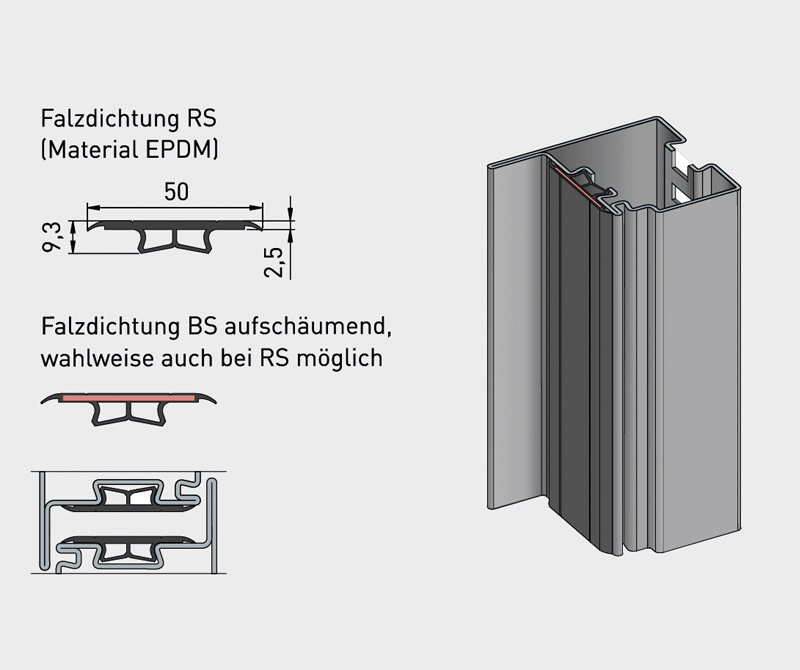

NovoFire® Steel T30 guarantees a 30-minute fire resistance period and prevents the spread of both fire and smoke during this time. The intumescent "Promaseal strip", which is integrated into the rubber profile of the door rebate, ensures safe fire protection. The NovoFire® Steel RS is recommended in situations where only smoke protection is required. This system, tested in accordance with DIN 18095 and DIN EN 1634-3, successfully prevents the passage of smoke and thus forms a reliable room closure.

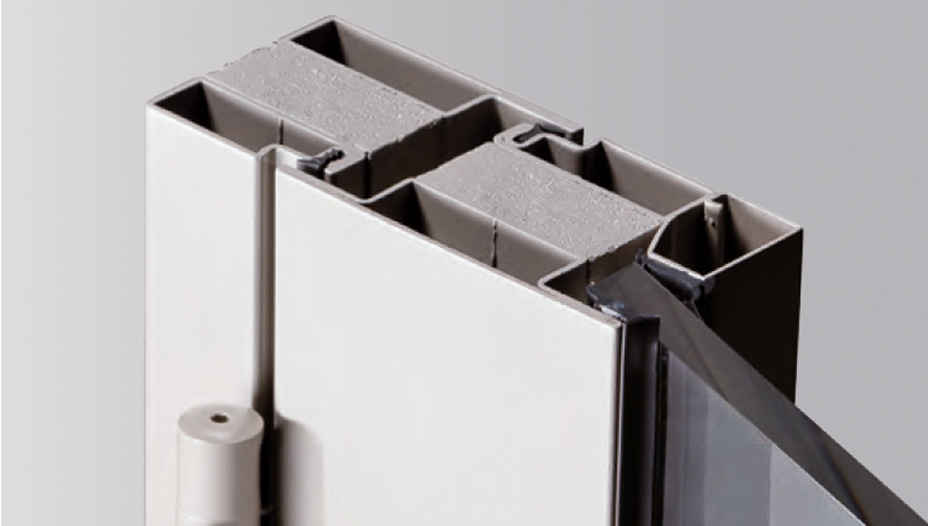

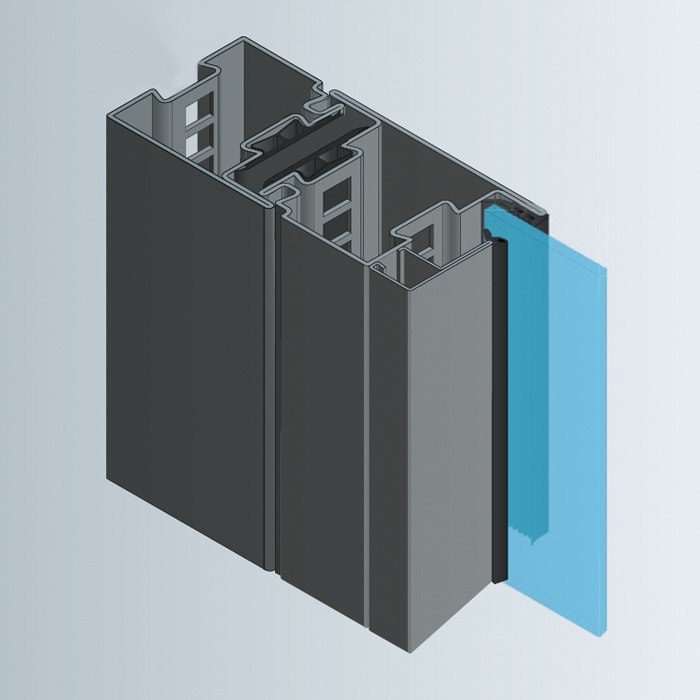

[1 ] Good appearance thanks to functional panel in the door rebate area, for smoke protection and fire protection

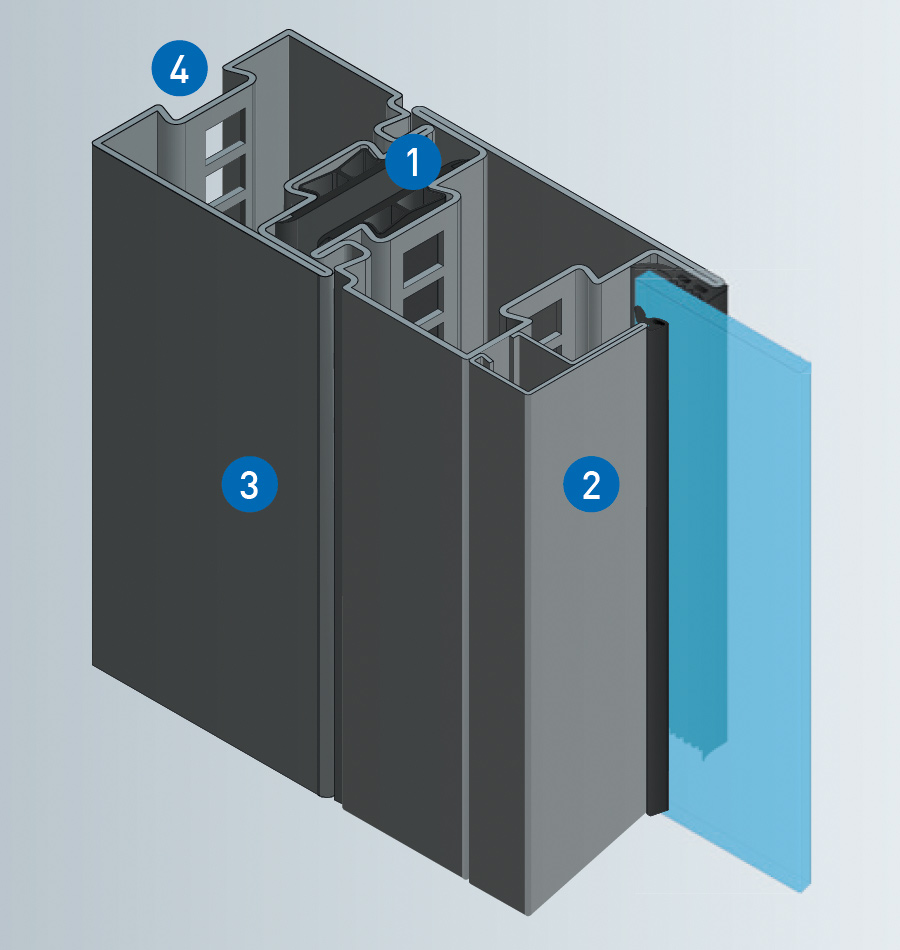

[2 ] A wide range of glazing bead variants is possible, including a glazing bead on both sides

[3 ] The basic profile is made of 100% recyclable steel and is always flush-mounted

[4 ] The unique multifunctional groove enables easy installation and fine adjustment of fittings

THAT SPEAKS IN FAVOUR OF THE NEW NOVOFIRE® STEEL TUBULAR FRAME DOORS FROM NOVOFERM

NovoFire® Steel combines decades of experience in the manufacture of tubular frame doors and in the field of fire and smoke protection in one system. The result is a system that is not only characterised by a high level of safety in an emergency, but also enables other applications such as automation, anti-panic function, access control or sound insulation.

The many advantages include

- Simple installation

- Outstanding design, great flexibility and robustness thanks to innovative profile geometry

- Generous dimensions

1-leaf: 1,560 mm x 3,000 mm

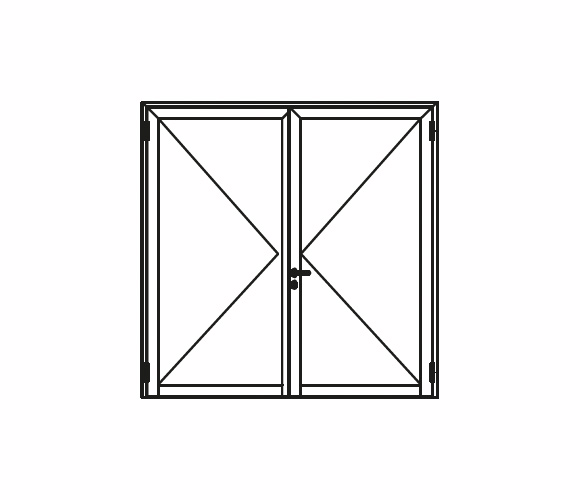

2-leaf: 3,000 mm x 3,000 mm - Widening profiles to increase the external frame dimensions

- Various fire-resistant glass and panels with different infills

- High dimensional stability in the event of fire (NovoFire® Steel T30)

Details steel systems

Details steel systems

NOVOFERM STEEL PROFILE FRAME SYSTEMS OFFER SAFETY AND COMFORT INSIDE AND OUTSIDE

Novoferm profile frame systems made of steel are ideal components for safe and at the same time aesthetically sophisticated applications in the field of smoke and fire protection closures.

The static properties of the basic material allow for unrivalled filigree structures with elegantly narrow face widths.

In addition to "Presto RS" for smoke protection and "Fuego light" for fire protection applications - both designed for interior use - we also offer "Unico", a profile construction for the construction of exterior door systems.

What's special about it: with its innovative thermal break, which completely dispenses with plastic, this system is fully recyclable.

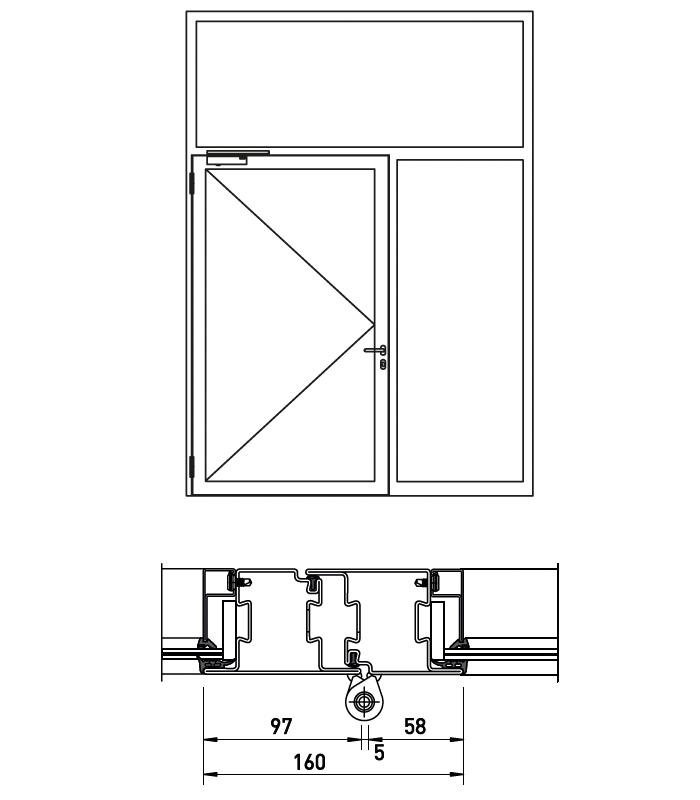

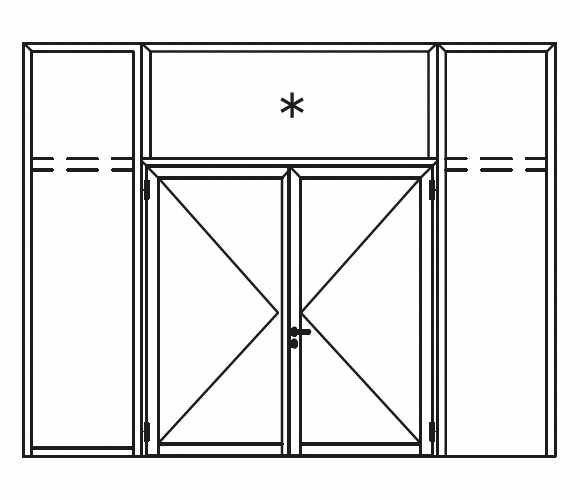

SYSTEM DESCRIPTION "PRESTO" AND "FUEGO LIGHT "*

Door element made of galvanised precision steel tubes. The door is tested as a smoke protection door using an automatically lowerable floor seal in accordance with DIN 18095. Face width of frame and sash 130 mm, plinth height 50, 70 - 420 mm, installation depth 50 mm. The leaf dimension of the inactive leaf must not be less than 500 mm for double-leaf doors. Units prepared for push-through or weld-on installation.

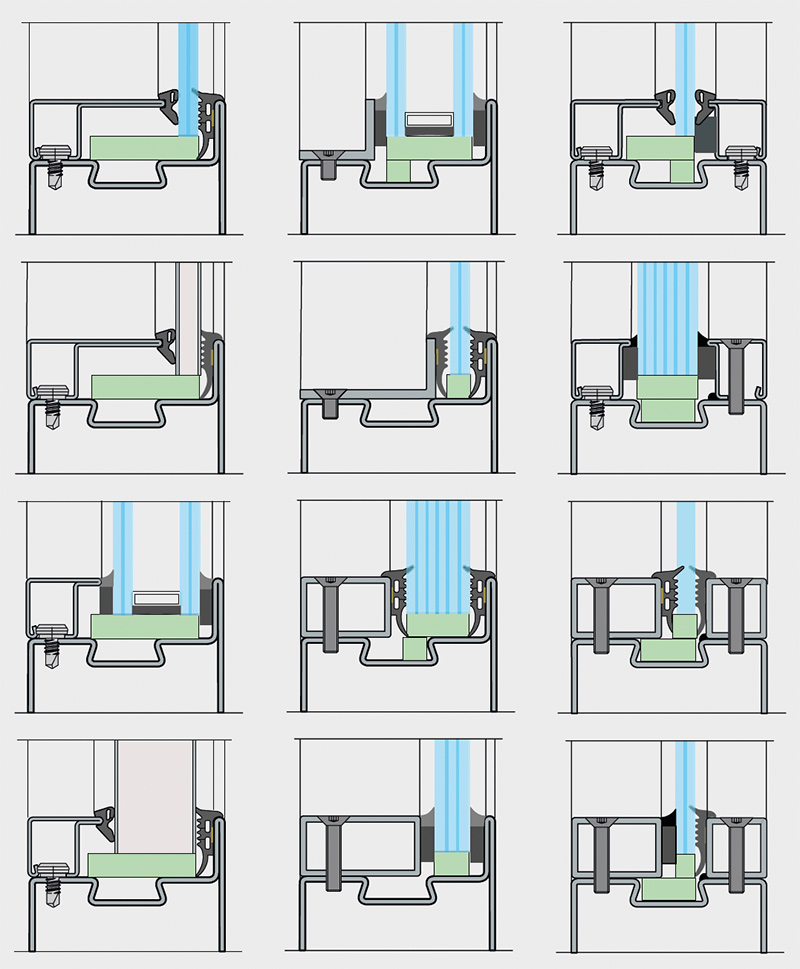

FITTINGS

Drop-in lock, prepared for profile cylinder, lever handle or interchangeable fittings with oval rosette in aluminium, stainless steel or PVC-U possible. Inactive leaf held by the top locking mechanism of the active leaf as standard, alternatively anti-panic function in accordance with DIN EN 179 or DIN EN 1125 possible. Overhead door closer with guide rail to DIN EN 1154, e.g. GEZE TS 5000 / Dorma TS 93, integrated door closing systems (GEZE Boxer / Dorma ITS 96), swing door drive to DIN 18263 / DIN 18650.

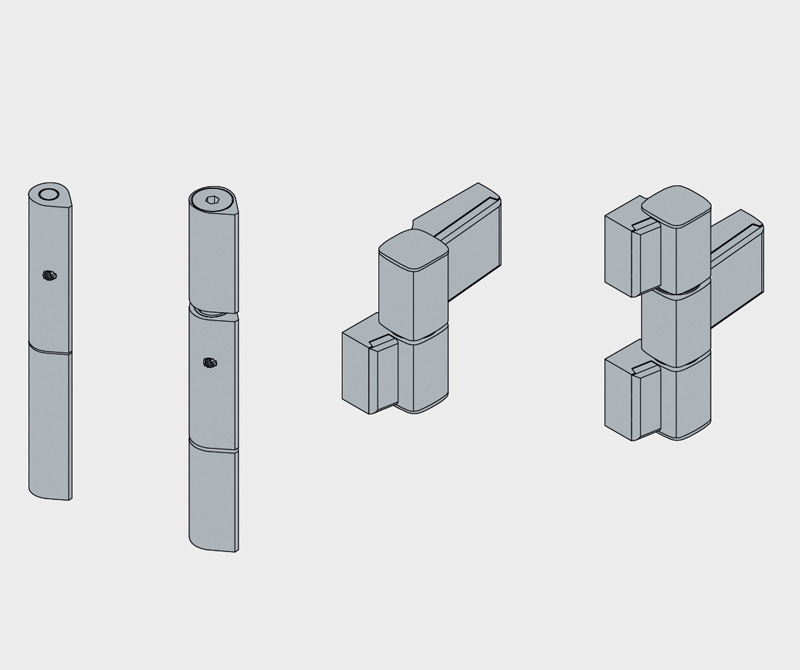

Hinges

Two 2-part steel weld-on hinges per leaf, adjustable in three dimensions; if the door is fitted with a swing door drive, we recommend three hinges. Other hinge variants such as screw-on hinges, roller hinges, integrated hinges possible.

SURFACE

Powder-coated primed RAL 9002 (grey-white) or optionally final painted (RAL Classic of your choice).

GLAZING

Safety glass VSG or ESG. Glazing variants and panel infills, profiles with single-sided glazing rebate and glazing beads on the opposite hinge side, dry glazing with EPDM seals.

FIXED GLAZING

Flush connections to the door, alternatively stand-alone possible, optionally bevelled or T-connections. The frame uprights must run uninterrupted over the entire height of the fixed glazing.

Steel as a material for quality and the environment

Steel as a material for quality and the environment

STEEL AS A MATERIAL - AN ADVANTAGE FOR QUALITY AND THE ENVIRONMENT

The construction industry is always looking for new strategies to work in the most environmentally friendly way possible. Examples include prioritising renovation over new construction or giving preference to raw materials from the region in order to keep transport routes short. However, the reusability of materials also plays an important role. Steel is particularly suitable here, as this material can be 100% recycled.

This is one of the reasons why Novoferm has launched NovoFire® Steel fire and smoke protection doors made of steel, which utilise this advantage and offer added sustainability.

THE THREE MOST IMPORTANT ADVANTAGES OF STEEL

100%RECYCLABLE

Steel can be reused an unlimited number of times, as this material can be recycled as often as required without any loss of quality. Old steel components are therefore not waste that needs to be disposed of, but the basis for new products.

EFFICIENT USE OF MATERIAL

Steel offers a high level of robustness even with very delicate geometries. This is partly due to its high modulus of elasticity and partly because steel can be welded. This means that very durable products can be manufactured using comparatively little material.

DURABILITY

Thanks to their excellent durability, steel systems remain in use for a long time. This significantly reduces the material and energy consumption that would be incurred if the system had to be replaced.

SUSTAINABILITY FROM NOVOFERM

Consume less, achieve more:

Efficient use of energy and other resources is an integral part of our corporate culture, as is continuous product and process optimisation in terms of sustainability. This enables us to offer our customers solutions with which modern sustainability requirements can be reliably realised.

Just like with NovoFire® Steel:

This system is not only made of recyclable steel, but also conserves important resources thanks to its system compatibility, simple retrofitting options and durability.

FOUR TIMES SUSTAINABILITY WITH NOVOFIRE® STEEL

SYSTEM COMPATIBILITY

The use of standardised fittings from the proven NovoFire® aluminium system saves resources, optimises cost-effectiveness and guarantees security based on many years of experience with the relevant technology.

UPGRADEABILITY

NovoFire® Steel can be easily retrofitted with various components. This allows the system to be subsequently adapted to changing requirements. A complete replacement is not necessary.

ROBUSTNESS

NovoFire® Steel is produced using a special manufacturing process. The profiles are made from hot-dip coated sheet metal, which guarantees high corrosion resistance, even in the hollow chambers.

ENVIRONMENTAL PRODUCT DECLARATIONS

Novoferm steel profile frame systems are produced in an environmentally friendly manner, as evidenced by various product declarations or verifications, including ISO 14025, EN 15804, ISO 14001 and in accordance with BREEAM, DGNB and LEED criteria.

Highlights “NovoFire Steel”

This animation presents the highlights of the Novoferm steel tubular frame doors "NovoFire Steel" in a visually appealing and condensed form.

You can find further animations at

Your plus points at a glance

- Tubular steel frame doors developed and manufactured in-house at attractive prices

- Available as fire protection door NovoFire Steel T30 / EI 30, Forster Fuego T90 / EI 90 and as smoke protection door NovoFire Steel RS

- Simple installation and fine adjustment with well thought-out details (e.g. unique multifunctional groove enables easy installation and fine adjustment of fittings, ...)

- Sustainability thanks to base profiles made from 100% recyclable steel

Steel profiles with a construction depth of 65 mm and a material thickness of 1.8 mm

- The intumescent "fire protection strip", which is integrated into the rubber profile of the door rebate, ensures reliable fire protection

- Available up to a size of BRM 1,560 x 3,000 mm (single leaf) or 3,000 x 3,000 mm (double leaf)

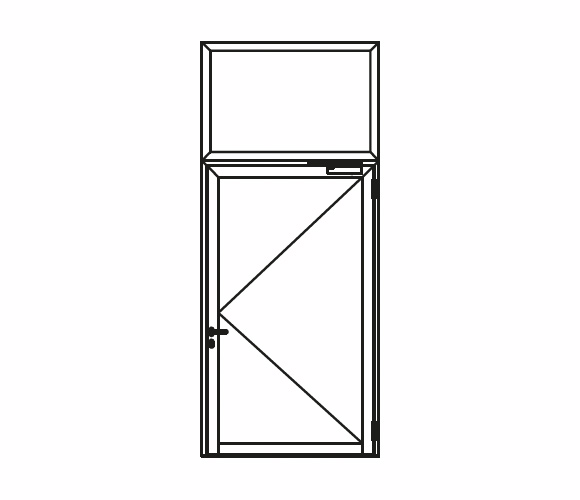

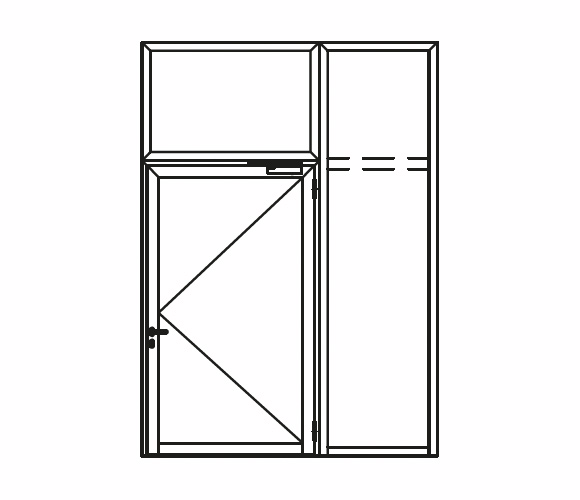

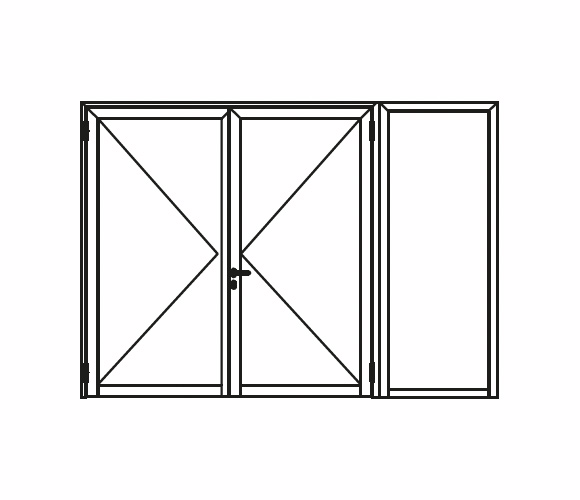

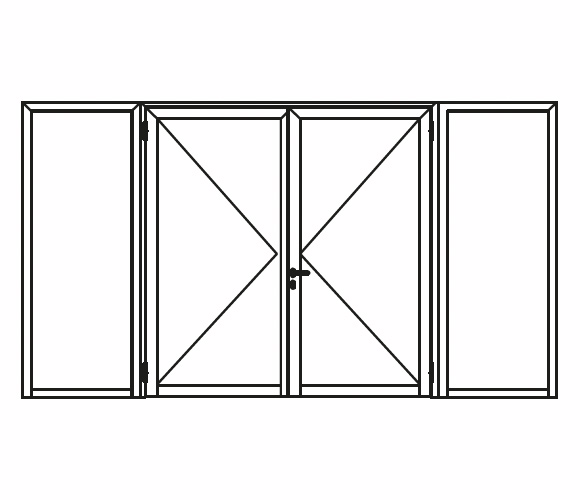

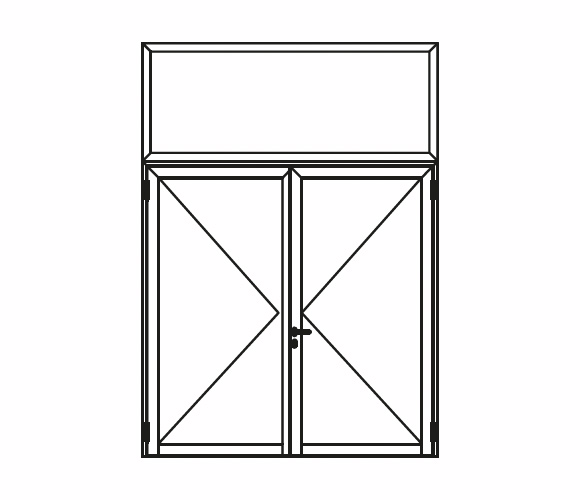

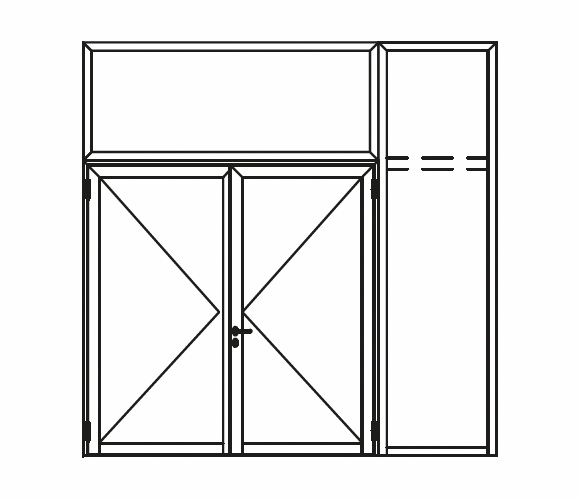

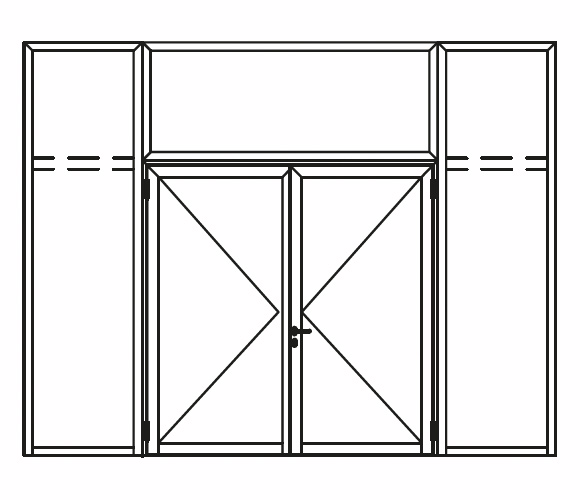

- Can be combined with side panels and/or fanlights

- Various fire-resistant glass and panels with different infills

- Large selection of glazing bead variants, hardware components and other fittings

Technology and details

Technical data NovoFire Steel RS

| Resistance class | RS | ||||

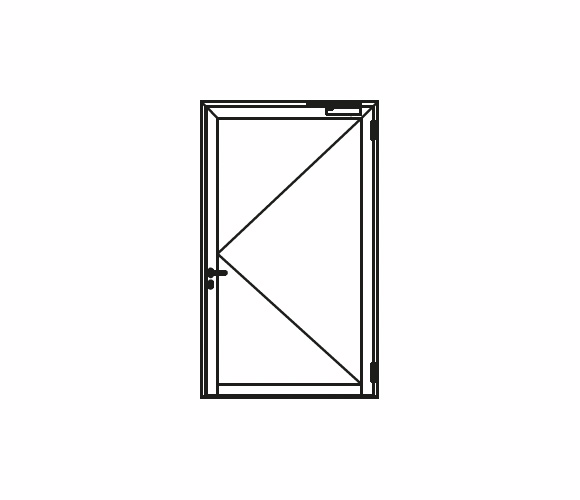

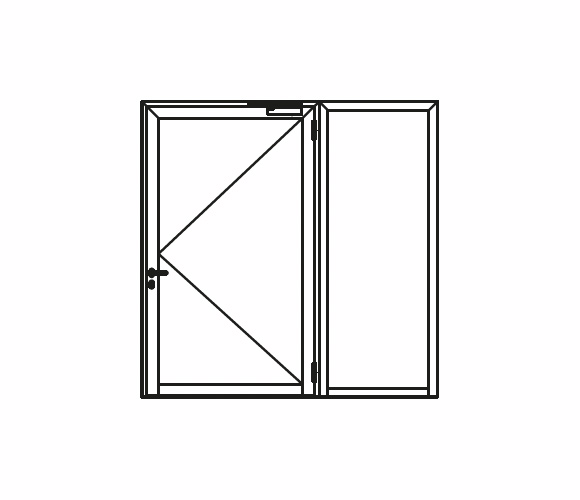

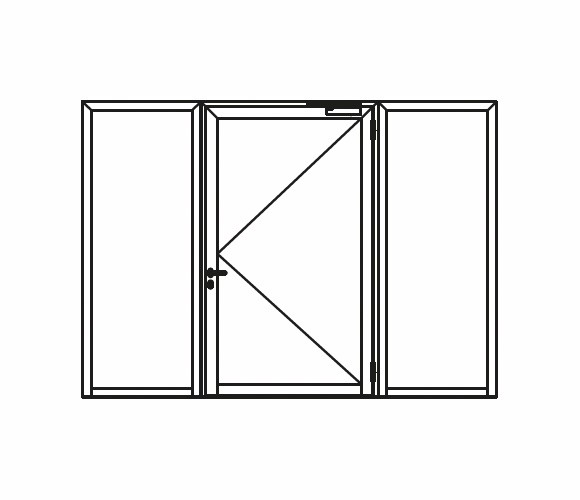

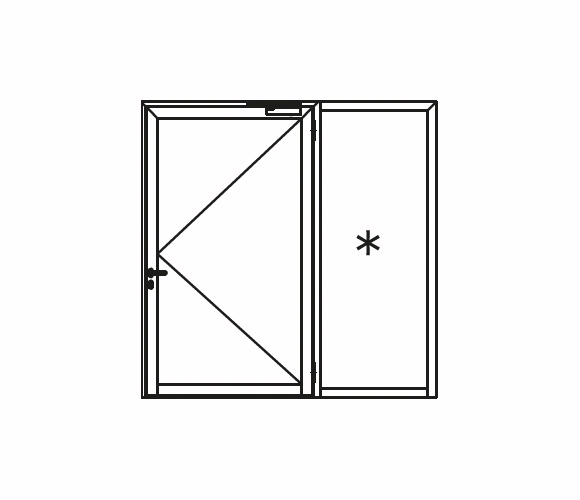

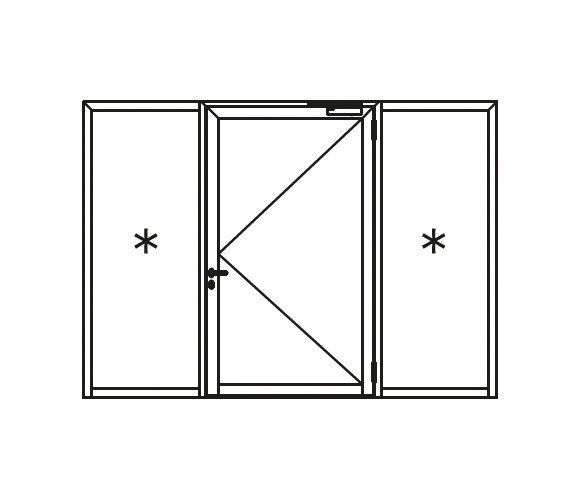

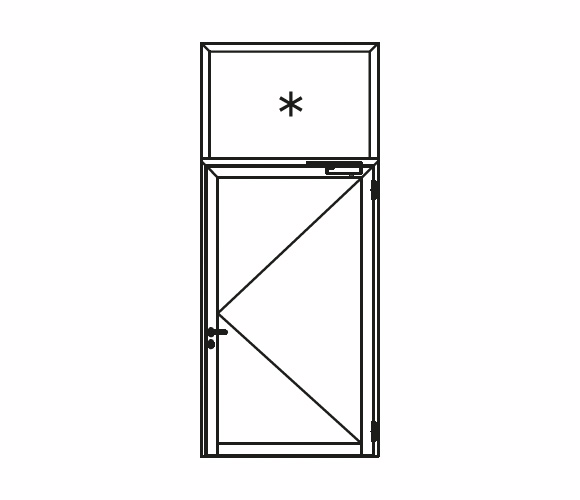

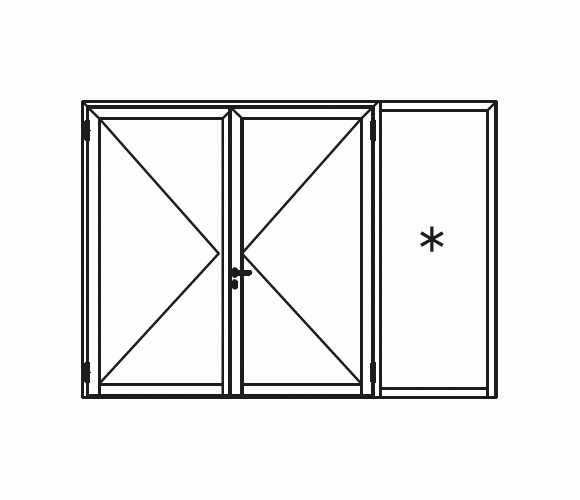

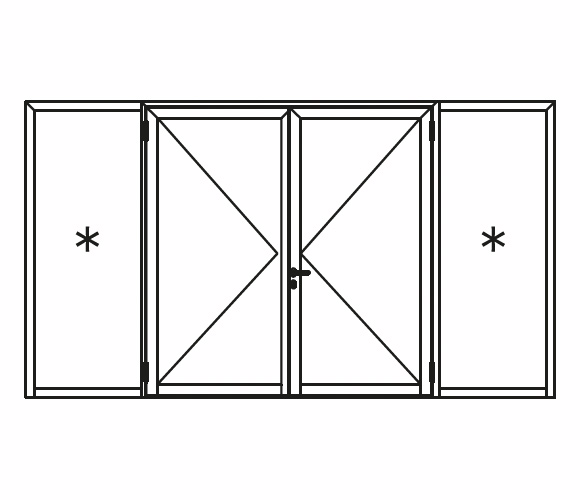

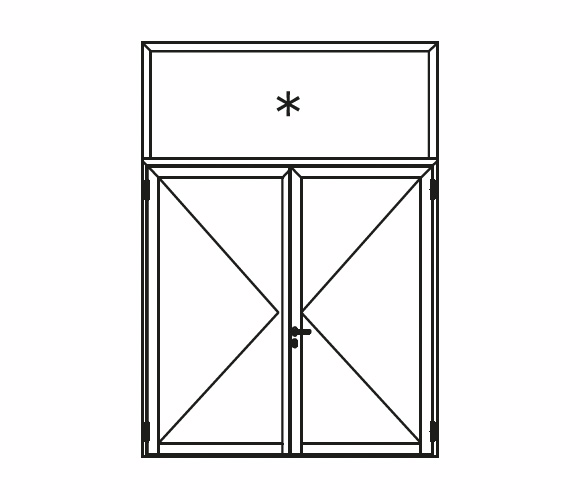

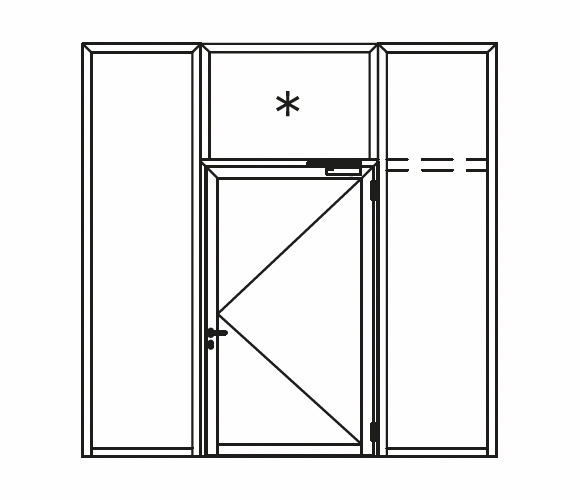

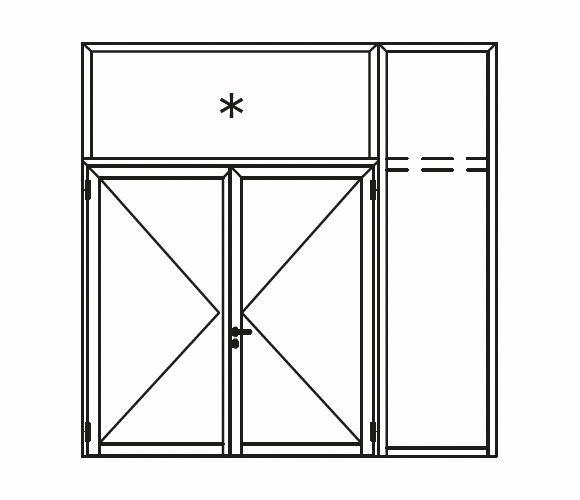

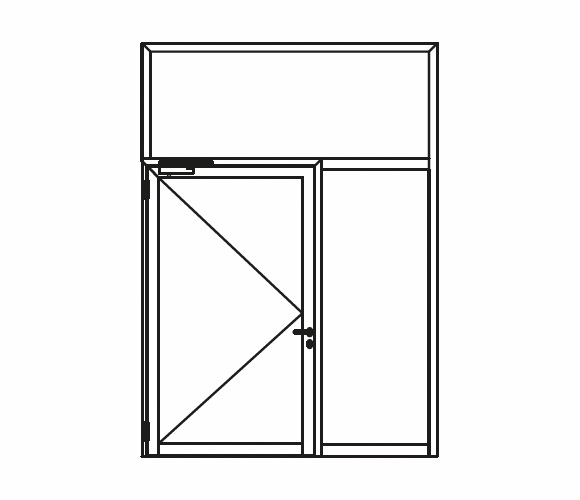

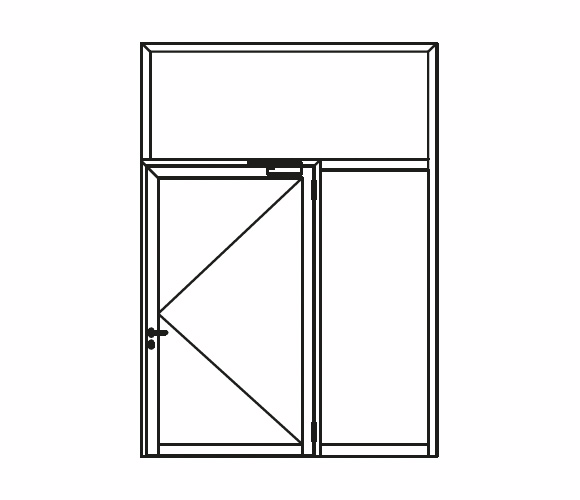

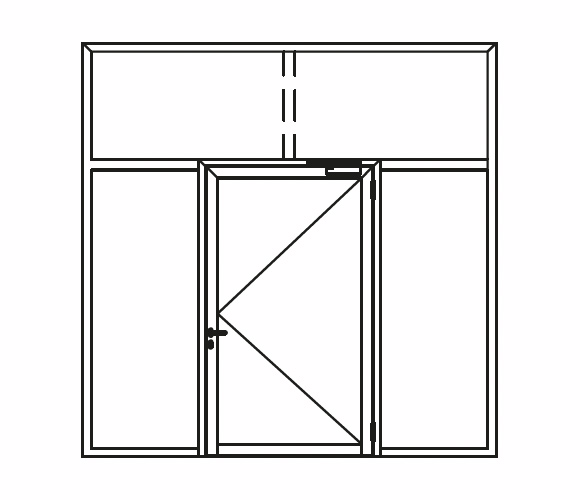

| Type designation | NovoFire® Steel RS-1 | NovoFire® Steel RS-1 combination door | NovoFire® Steel RS-2 | NovoFire® Steel RS door with fixed glazing | |

| Models | |||||

| Vertical glazing bars per sash | 1 | 1 | 1 | Any | |

| Horizontal glazing bars per sash | 2 | 2 | 2 | Any | |

| Panel division | |||||

| Slopes | - | - | - | - | |

| Round arches | - | - | - | - | |

| Recesses | - | - | - | - | |

| angle | - | - | - | - | |

| Widening | - | - | - | - | |

| Dimensions | |||||

| Overall dimensions | Width: Min. - max. | 625 - 1840* | ≤ 3840* | 1350 - 3280* | Unlimited 1) |

| Height: Min. - max. | 1750 - 3140* | ≤ 4140* | 1750 - 3140* | ≤ 4160 | |

| External frame dimensions | Width: Min. - max. | 585 - 1800* | 2585 - 3800* | 1310 - 3240* | Unlimited 1) |

| Height: Min. - max. | 1730 - 3120* | 2730 - 4120* | 1740 - 3120* | ≤ 4000 | |

Clear passage with | Width: Min. - max. | 431 - 1406 | 431 - 1406 | 1156 - 2846 | - |

| Height: Min. - max. | 1653 - 2923 | 1653 - 2923 | 1653 - 2923 | - | |

| Min. opening width GF: | - | - | 500 | - | |

| Max. Opening width GF: | - | - | 1474 | - | |

| Door leaf | |||||

| Construction depth | 65 | 65 | 65 | 64 | |

| View | 140 | 140 - 160 | 140 | 73 | |

| Plinth height | 93 | 93 | 93 | 73 - 93 | |

| Glued rung/ transom profile | 20 - 100/ 93 | 20 - 100/ 93 | 20 - 100/ 93 | 20 - 100/ 93 | |

| Walls | |||||

| Masonry | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Concrete | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | |

| Aerated concrete blocks or flat blocks (strength class 4) | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Aerated concrete slabs according to approval (strength class 4.4) 1) | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Assembly walls (height ≤ 5 m) steel, with panelling on both sides 2) | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | |

| Timber stud frame (height ≤ 5 m) with panelling on both sides 2) | ≥ 130 | ≥ 130 | ≥ 130 | ≥ 130 | |

| Clad steel supports | - | - | - | - | |

| Clad wooden columns | - | - | - | - | |

| Combination glazing/door | - | - | - | - | |

| Z-frame | - | - | - | - | |

| Fillings | |||||

| VSG or ESG | - | - | - | - | |

| Panel | - | - | - | - | |

Sealing to the glass | Dry glazing (rubber seal) | - | - | - | - |

| Wet glazing (facing tape) | - | - | - | - | |

| Design variants | |||||

| With fanlight and side panel | - | - | - | - | |

| With fanlight | - | - | - | - | |

| With side panel | - | - | - | - | |

| Sound insulation design max. Rw,P (Rw,R) | 42 (37) | - | 42 (37) | - | |

| AbP no. General building authority test certificate | P-5022 DMT DO | P-5022 DMT DO | P-5022 DMT DO | 1) | |

- = Possible - = Not possible RAM = External frame dimensions All dimensions in mm. * Including frame widening (max. 120 mm, right left and top). | |||||

Technical data NovoFire Steel T30 / EI 30

| Resistance class | T30 | ||||

| Type designation | NovoFire® Steel | NovoFire® Steel | NovoFire® Steel | NovoFire® Steel | |

| Models | |||||

| Vertical bars per sash | 1 | 1 | 1 | Any | |

| Horizontal glazing bars per sash | 2 | 2 | 2 | Any | |

| Panel division | |||||

| Slopes | - | - | - | - | |

| Round arches | - | - | - | - | |

| Recesses | - | - | - | - | |

| angle | - | - | - | - | |

| Widening | - | - | - | - | |

| Dimensions | |||||

| Overall dimensions | Width: Min. - max. | 625 - 1840* | ≤ 3840* | 1350 - 3280* | Unlimited |

| Height: Min. - max. | 1750 - 3140* | ≤ 4140* | 1750 - 3140* | ≤ 4160 | |

| External frame dimensions | Width: Min. - max. | 585 - 1800* | 2585 - 3800* | 1310 - 3240* | Unlimited |

| Height: Min. - max. | 1730 - 3120* | 2730 - 4120* | 1740 - 3120* | ≤ 4000 | |

Clear passage with | Width: Min. - max. | 431 - 1406 | 431 - 1406 | 1156 - 2846 | - |

| Height: Min. - max. | 1653 - 2923 | 1653 - 2923 | 1653 - 2923 | - | |

| Min. opening width GF: | - | - | 500 | - | |

| Max. Opening width GF: | - | - | 1474 | - | |

| Door leaf | |||||

| Construction depth | 65 | 65 | 65 | 64 | |

| View | 140 | 140 - 160 | 140 | 73 | |

| Plinth height | 93 | 93 | 93 | 73 - 93 | |

| Glued rung/ transom profile | 20 - 100/ 93 | 20 - 100/ 93 | 20 - 100/ 93 | 20 - 100/ 93 | |

| Walls | |||||

| Masonry | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Concrete | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | |

| Aerated concrete blocks or flat blocks (strength class 4) | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Aerated concrete slabs according to approval (strength class 4.4) 1) | ≥ 150 | ≥ 150 | ≥ 150 | ≥ 150 | |

| Assembly walls (height ≤ 5 m) steel, with panelling on both sides 2) | ≥ 100 | ≥ 100 | ≥ 100 | ≥ 100 | |

| Timber stud frame (height ≤ 5 m) with panelling on both sides 2) | - | - | - | - | |

| Clad steel columns | - | - | - | - | |

| Clad wooden columns | - | - | - | - | |

| Combination glazing/door | - | - | - | - | |

| Z-frame | - | - | - | - | |

| Fillings | |||||

| VSG or ESG | - | - | - | - | |

| Panel | - | - | - | - | |

Sealing to the glass | Dry glazing (rubber seal) | - | - | - | - |

| Wet glazing (facing tape) | - | - | - | - | |

| Design variants | |||||

| With fanlight and side panel | - | - | - | - | |

| With fanlight | - | - | - | - | |

| With side panel | - | - | - | - | |

| Sound insulation design max. Rw,P (Rw,R) | 42 (37) | - | 42 (37) | - | |

| AbP no. General building authority test certificate | Z-6.20-... 3) | Z-6.20-... 3) | Z-6.20-... 3) | Z-6.20-... 3) | |

- = Possible - = Not possible RAM = External frame dimensions All dimensions in mm. * Including frame widening (max. 120 mm, right left and top). | |||||

Technical data Forster Fuego T90 (EI 90)

| Resistance class | T90 (EI2 90) / F90 | ||||

| Type designation | Fuego light | Fuego light | Fuego light | ||

| Element layout | |||||

| Slopes | - | - | - | ||

| Round arches | - | - | - | ||

| Recesses | - | - | - | ||

| angle | - | - | - | ||

| Widenings | - | - | - | ||

| Dimensions | |||||

| Overall dimensions | Width min. - max. | 740 - 1580 | 1440 - 2530 | unlimited ¹) | |

| Height min. - max. | 1745 - 2590 | 1745 - 2590 | 4020 | ||

| Height (with fanlight) | 1845 - 4020 | 1845 - 4020 | - | ||

| Outer frame dimension | Width min. - max. | 700 - 1540 | 1400 - 2490 | unlimited ¹) | |

| Height min. - max. | 1725 - 2570 | 1725 - 2570 | 4000 | ||

| Height (with fanlight) | 1825 - 4000 | 1825 - 4000 | - | ||

| Clear passage with 180° opening | Width min. - max. | 560 - 1400 | 1260 - 2350 | - | |

| Height min. - max. | 1655 - 2500 | 1665 - 2500 | - | ||

| Door leaf | |||||

| Construction depth | 70 | 65 | 65 | ||

| View | 130 | 130 / 150 | 70 / 90 | ||

| Plinth height | 90, 140-340 | 90, 140-340 | 90, 140-340 | ||

| Transom profile | 90 | 90 | 90 | ||

| Glued rung | 30, 50 (up to 200) | 30, 50 (up to 200) | 30, 50 (up to 200) | ||

| Walls | |||||

| Masonry | ≥ 175 ²) | ≥ 175 ²) | ≥ 175 | ||

| Concrete | ≥ 140 ³) | ≥ 140 ³) | ≥ 140 | ||

| Aerated concrete block or plane blocks | ≥ 240 4) | ≥ 240 4) | ≥ 240 | ||

| Aerated concrete slabs | ≥ 150 4) | ≥ 150 4) | ≥ 150 | ||

| Stud walls Transoms and Steel studs | ≥ 100 ³) 4) | ≥ 100 ³) 4) | ≥ 100 ³) 4) | ||

| Stud walls, transoms and studs made of wood | - | - | - | ||

| Clad steel component | - | - | - | ||

| clad wood component | - | - | - | ||

| Combination door/ glazing | - | - | - | ||

| Z-frame | - | - | - | ||

| Fillings | |||||

| Pyrostop 90-102 max. Width x height | 1304 x 2364 | 1304 x 2364 | 1350 x 2800 | ||

| Panel, max. width x height | 1064 x 2184 | 1064 x 2184 | 1305 x 2185 | ||

| Glass / panel | - | - | - | ||

| Glass insert | Wet glazing | - | - | - | |

Dry glazing | - | - | - | ||

| Design variants | |||||

| with fanlight and side panel | • | - | - | ||

| with fanlight | - | - | - | ||

| with side panel | - | - | - | ||

| Smoke protection door according to DIN 18095 and DIN EN 1634 - Part 3 (in combination with DIN 4102) | - | - | - | ||

| Sound insulation design maximum Rw,P (Rw,R) | - | - | - | ||

| Burglar resistance | - | - | - | ||

| Thermal transmittance Uf | - | - | - | ||

| Test certificate/ Approval numbers | Z-6.20-1881 | Z-6.20-1881 | Z-19.14-1973 | ||

| Tested according to | DIN 4102 and DIN EN 1634 | ||||

| - possible - not possible ¹) according to static requirements ²) up to RAM 2400 x 2600 with fanlight and side section, for masonry 240 RAM up to 4500 x 3500, up to height 4000 only with fanlight ³) up to RAM 4500 x 3500 with fanlight and side section, up to height = 4000 only with fanlight 4) Hollow steel profile min. 50 x 50 x 4 required | |||||

| All dimensions in mm, RAM = external frame dimensions | |||||

Technical steel external closures

| Resistance class | Thermally insulated external closures | |||

| Type designation | 1-leaf door | 2-panel door | Glazing ²) | |

| Element layout | ||||

| Slopes | - | - | - | |

| Round arches | - | - | - | |

| Recesses | - | - | - | |

| Angle | - | - | - | |

| Widening | - | - | - | |

| Dimensions | ||||

| Overall dimensions | Width min. - max. | 6300 - 1530 | 1500 - 2400 | unlimited ¹) |

Height min. - max. | 1765 - 3015 | 1740 - 2400 | 5000 ¹) | |

| Outer frame dimension | Width min. - max. | 600 - 1500 | 1400 - 3000 | unlimited ¹) |

Height min. - max. | 1750 - 3000 | 1750 - 3000 | 5000 ¹) | |

| Clear passage | Width min. - max. | 460 - 1360 | 1260 - 2860 | - |

| with 180° opening | Height min. - max. | 1680 - 2930 | 1680 - 2930 | - |

| Door leaf | ||||

| Construction depth | 65 | 65 | 65 | |

| View | 130 | 130 / 150 | 70 / 90 | |

| Plinth height | 70, 90, 140 - 340 | 70, 90, 140 - 340 | 70, 90, 140 - 340 | |

| Transom profile | 90 | 90 | 90 | |

| Glued rung | 30, 50, (up to 400) | 30, 50, (up to 400) | 30, 50, (up to 400) | |

| Walls | - | - | - | |

| Masonry | - | - | - | |

| Concrete | - | - | - | |

| Aerated concrete block or flat blocks | - | - | - | |

| Aerated concrete slabs | - | - | - | |

| Stud walls | - | - | - | |

| Clad steel component | - | - | - | |

| clad wood component | - | - | - | |

| Combination door / glazing | - | - | - | |

| Z-frame | - | - | - | |

| Fillings | ||||

| Glazing thickness 4) | 20-54 mm | |||

| Panel | - | - | - | |

| Glass / Panel | - | - | - | |

| Glass insert | Wet glazing | - | - | - |

Dry glazing | - | - | - | |

| Design variants | ||||

| with fanlight and side panel | - | - | - | |

| with fanlight | - | - | - | |

| with side panel | - | - | - | |

| Joint permeability class | 4 | 4 | 4 | |

| Driving rain tightness class | up to 5A | up to 5A | - | |

| Sound insulation | 47 dB | 47 dB | 47 dB | |

| Burglar resistance | WK 1-3 | WK 1-3 | - | |

| Thermal transmittance Uf | > 1.4 - 1.9 W/m²K | > 1.4 - 1.9 W/m²K | > 1.4 - 1.9 W/m²K | |

| CE marking according to EN 14351-1 | - | - | - | |

| Tested according to | DIN 4102 and DIN EN 1634 | |||

| - possible - not possible ¹) according to static requirements ²) no façade, no tilt/turn windows ³) Other sizes possible 4) All commercially available glass is available | ||||

| All dimensions in mm, RAM = external frame dimension | ||||

Montage

SIMPLE ASSEMBLY

Below you will find an extract of the numerous advantages for simple installation and the many installation options for Novoferm NovoFire Steel tubular frame doors.

Assembly and fine adjustment

ASSEMBLY AND FINE ADJUSTMENT - ALL ADVANTAGES AT A GLANCE

GLAZING

NovoFire® Steel glazing offers maximum flexibility in terms of design, type of glass and glazing technology. The doors can be designed with one or two side panels and/or fanlights. Mono or insulating glazing or panels with infills made of other materials can be used as infills. The panel thickness is between 6 and 34 mm. NovoFire® Steel doors can be manufactured in fixed glazing individually as U-connectors, in frame construction or as a combination of both.

With regard to glazing technology, both dry glazing (black EPDM glazing gasket on the outside) and wet glazing (with a glazing tape) are possible.

DECISIONS

A large selection of tested and approved fittings leaves nothing to be desired.

The use of standardised components ensures effective and economical production and installation.

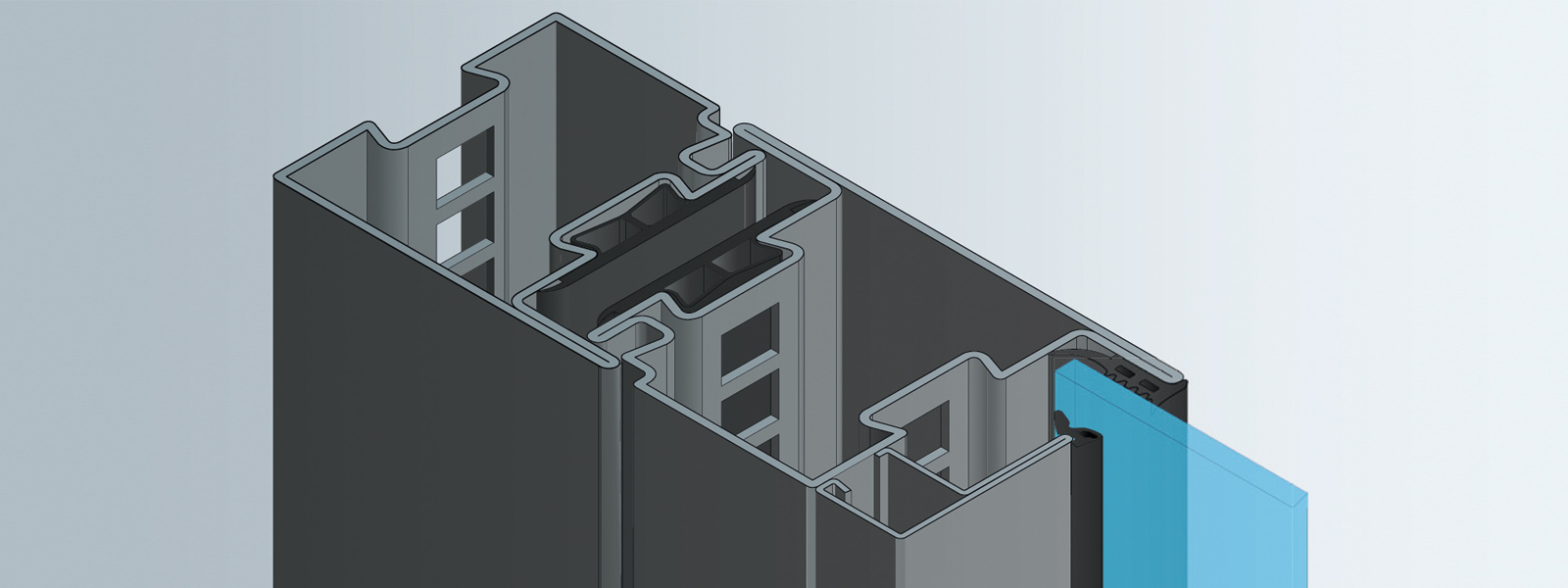

PROFIL

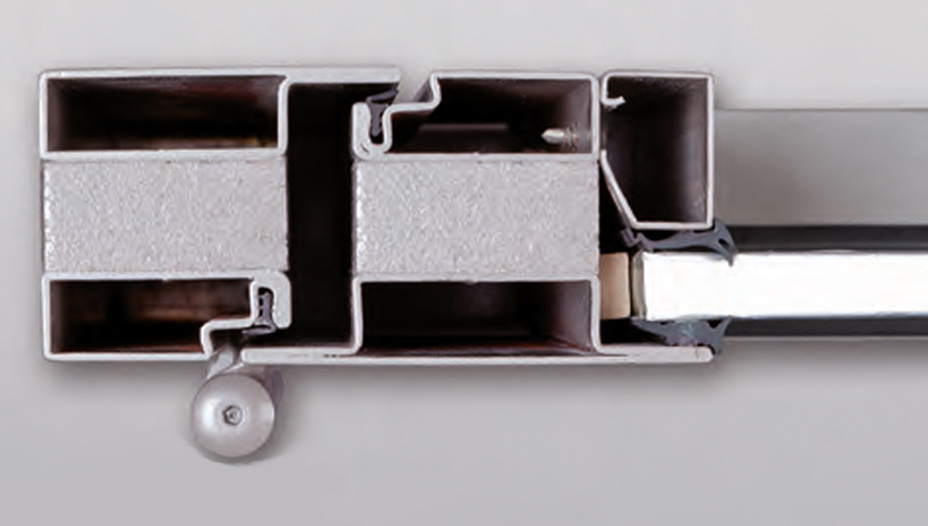

The centrepiece of the NovoFire® Steel platform is a steel profile with a construction depth of 65 mm and a material thickness of 1.8 mm.

Thanks to its new profile geometry and multifunctional groove, it is compatible with the components of our cross-system hardware platform. The regular punched holes in the profile make it easier to fasten the structure and connect it to other elements in the frame construction.

These punched holes also make it easy to lay cables for the electrification of the door, both during production and at a later date.

BANDS

The NovoFire® Steel T30/ RS utilises the newly developed weld-on door hinge, which sets new standards thanks to its maintenance-free nature and ease of adjustment even after installation.

Furthermore, there is a choice of several hinge designs to fulfil all functional requirements and perfect the door design at the same time.

DOOR FOLDING AREA

The functional cover made of EPDM ensures a good appearance in the door area. The cover is available in two versions:

As a variant for smoke protection and as a variant for fire protection. In addition to safety and design, the functional cover also improves the maintenance properties of the doors.

This is because both the material and the fact that this system has no profile edges make cleaning easier and support hygienic, germ-free cleanliness.

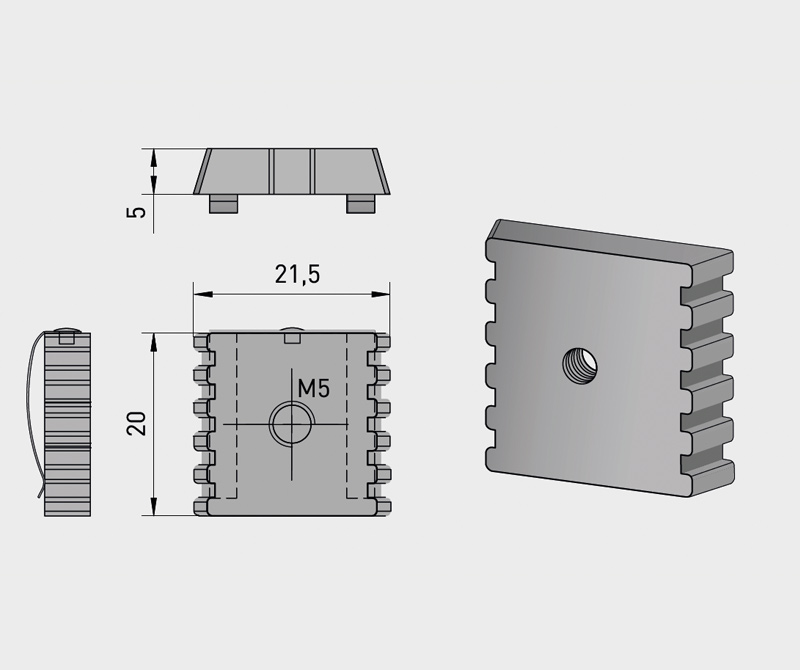

CLAMP PLATE

A clamping plate allows all installation parts to be flexibly fastened in the multifunctional groove in just a few steps.

Subsequent fine adjustment of the fittings is possible at any time.

REBATE ESPAGNOLETTE GUIDE

A unique and simple guide keeps the rebate espagnolette bar in the correct position and dampens the clicking noise caused by the locking bar when the door falls into the lock.

The guides can be retrofitted at any time, even during operation.

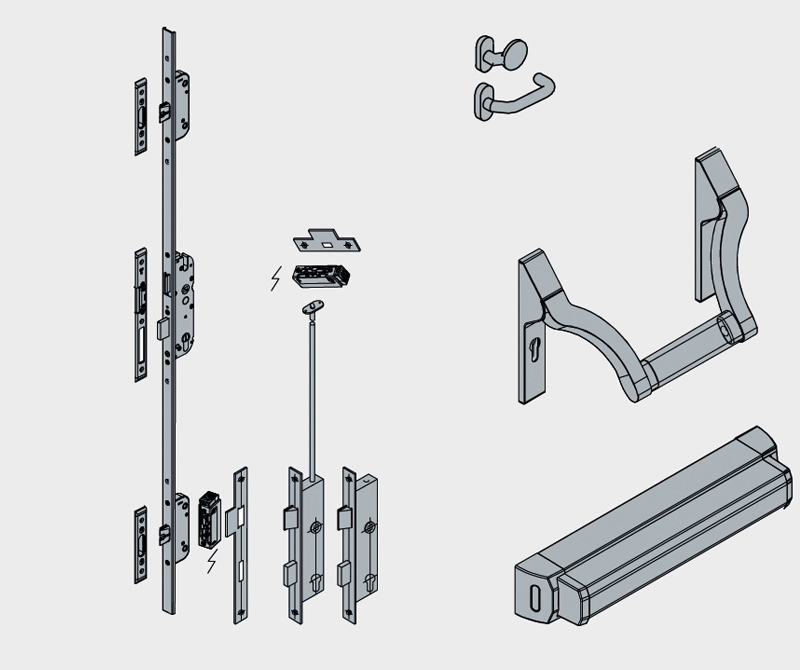

Installation variants and element coupling

Installation variants and element coupling

MONTAGEVARIANTEN

MIXED CONSTRUCTION

Combination of prefabricated elements with mounting joint (E) and (U) for easy installation in confined spaces.

DIFFERENT COUPLINGS OF THE GLAZING

ELEMENT COUPLING

U-COPLING

MIXED CONSTRUCTION

KOMBITÜR

* Fixed glazing connected to the door in a U-shape

ELEMENT COUPLING

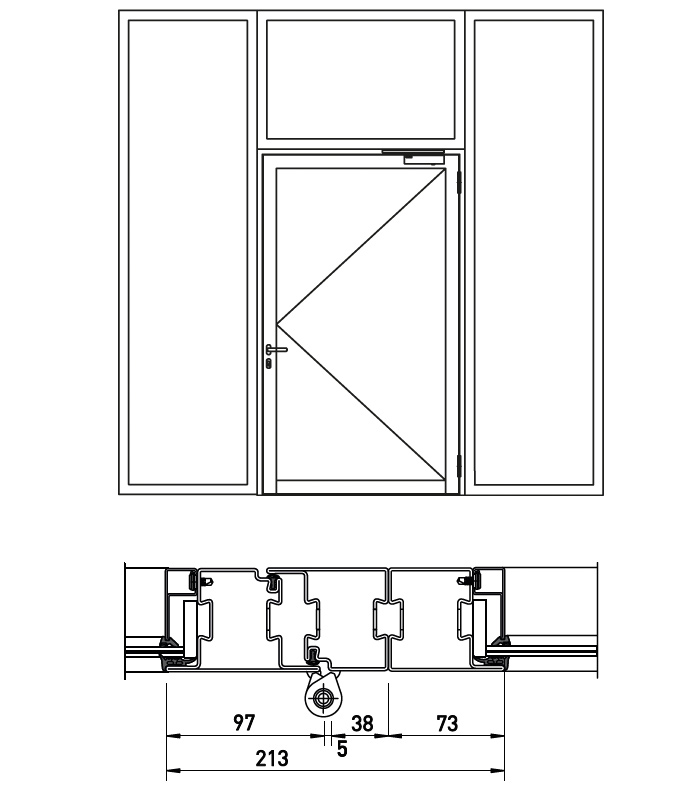

As soon as the RAM of the fixed glazing (optionally as a fanlight or side section) is < 1,000 mm, the coupling takes place element by element.

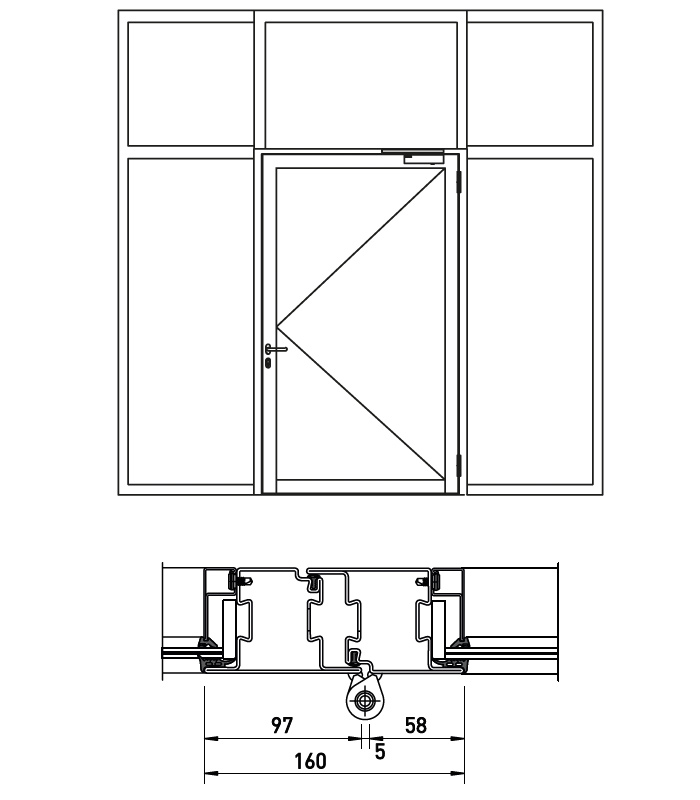

U-GLAZING

Fixed glazing (optionally as a fanlight or side panel) may only be coupled to the single or double-leaf door in a U-shape if the RAM of the fixed glazing does not exceed 1,000 mm. In addition, the side section of the fixed glazing may only be coupled to the single or double-leaf door in a U-shape if the door does not have a fanlight!

LOCKING TO THE TOP

A lock with additional locking to the top is required for clearances > 2,423 mm; a multi-point lock can be installed as an option.